- The screen is made of a new special material, which is anti-corrosion.

- Long service life and low failure rate.

- The screen’s height can be adjusted according to the actual situation, effectively controlling the flow of materials.

- The sieve hole is not easily blocked, reducing maintenance times and costs.

- Stable operation and low noise.

- Fully automatic control can be realized, making the operation simple and convenient.

- Long service life, wide range of use, not affected by bad weather.

- It is convenient and flexible to move, easy to install, and no foundation is required.

- Simple structure and easy maintenance.

- Moderate price and high-cost performance.

- Various specifications and models of sand screening machines can be customized according to user needs.

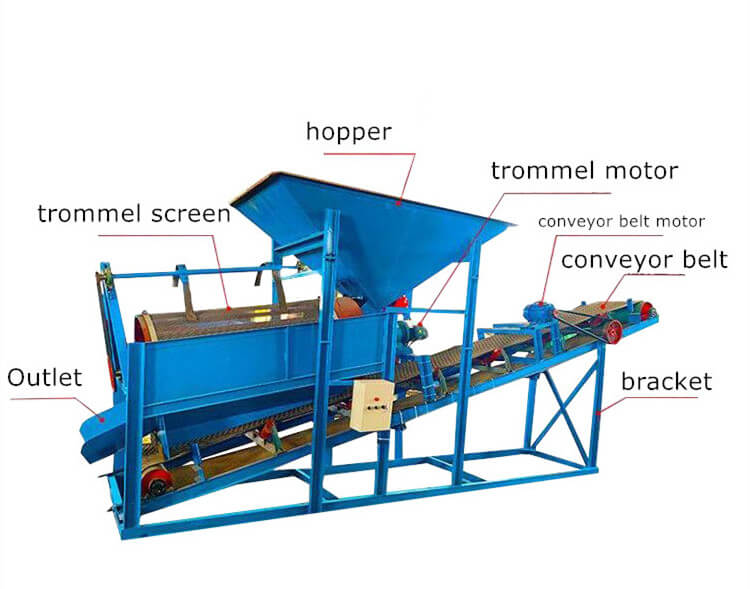

【Rotary Sand Screening Machine Structure】

The drum sand screening machine mainly comprises a cylindrical drum, rack, hopper, reducer, motor, conveyor belt, inlet and outlet.

【Rotary Sand Screening Machine Working Principle】

Imitating the working principle of manually using the inclined screen to sieve sand, after the stone enters the drum through the hopper, the motor rotates the drum through the pulley and gear transmission. When the drum rotates at a high speed, a strong centrifugal force will be generated on the surface of the drum so that the sand on the screen will be thrown out and the sand and stones will be separated.

| Model | Capacity(m3/h) | Hopper Size(m) | Screen Size(m) | Conveyor Belt Size(m) | Mesh Size(mm) | Motor Power(Main Motor + Screen Motor + Vibration Motor) | Dimensions(m) |

| JXSC-S20 | 20 | 2.3*1.1 | 1.5*0.6 | 4*0.5 | 8mm (replaceable) | 4kw + 3kw + 0.5kw | 4.3*1.1*2.2 |

| JXSC-S30S | 30-50 | 2.7*1.1 | 2*0.6 | 6*0.5 | 4kw + 3kw + 0.5kw | 6*1.1*2.4 | |

| JXSC-S30L | 60-80 | 3.5*1.5 | 3*0.8 | 8*0.8 | 7.5kw + 4kw + 0.5kw | 8.2*1.6*3.2 | |

| JXSC-S50 | 100-140 | 3.8*1.6 | 3.5*1 | 9*1 | 11kw + 4kw + 0.5kw | 9.3*2*3.5 | |

| JXSC-S80 | 130-160 | 4.1*1.7 | 4*1.2 | 11*1.2 | 15kw + 5.5kw + 0.5kw | 11*2.2*3.7 |

Rotary Sand Screening Machine Introduction

Rotary sand screening machine is also called roller sand screening machine, and drum sieving machine, which can wet and dry sieving. The drum screening machine is equipment that screens sand and gravel by means of a drum sieve. It can be used in combination with the sand washing machine and can also be used independently with the installation bracket. It is an ideal choice for small sand screening machines.

Features

- The sieve hole is not easy to be blocked.

- Stable operation and low noise.

- Simple structure and easy maintenance.

- The screening cylinder can be closed, which makes it easy to seal and collect dust.

- The whole machine has high reliability and less one-time investment.

- Adopt special screens, high screening efficiency, and long service life.

Application

- In the quarry, it is used for grading large and small stones and separating soil and stone powder.

- It is used for sand and stone separation in the sand and gravel field.

- The coal industry separates lump coal and coal powder and coal washing (a component of coal washing machinery).

- The chemical and mineral processing industries are used for grading large and small lumps and separating powdery substances.

Our Rotary Sand Screening Machine

The sand screening machine we produced has many characteristics such as simple structure, convenient movement, easy operation, heavy workload, durability, low production cost, high efficiency, and convenient maintenance. The processed sand, sand, gravel, river sand, Automatic separation of mixed materials such as weathered stones, suitable for mixing plants, road and bridge projects, construction sites, sand quarries and sand and gravel factories, large-scale projects, and small construction sites. It is an ideal equipment to save manpower and financial resources, improve project quality, speed up project progress, and increase economic benefits.

- Motor

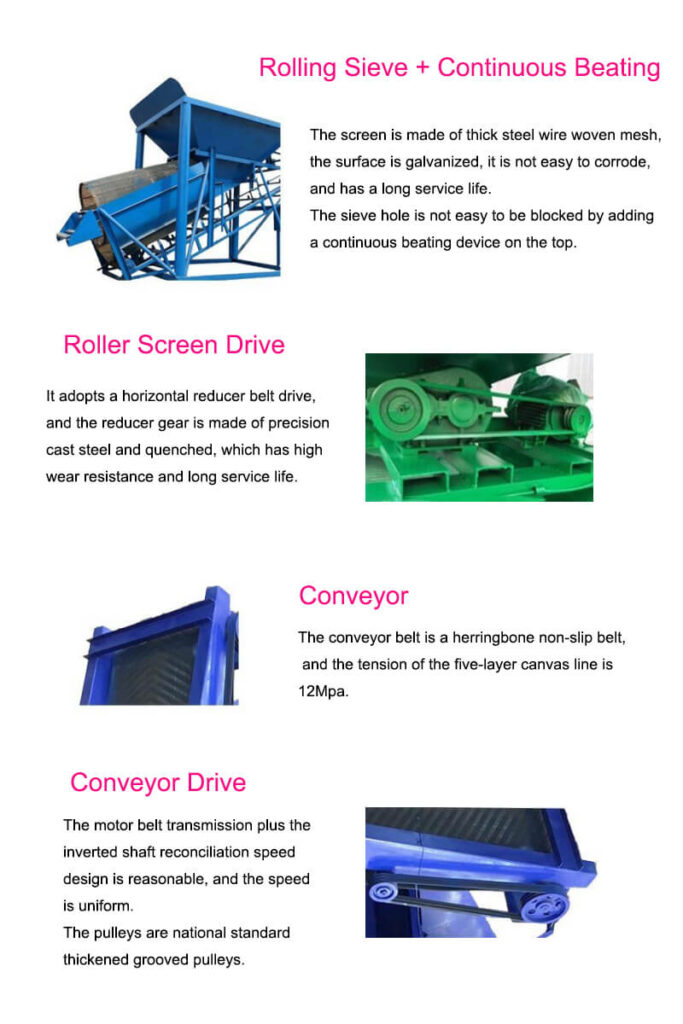

High-power three-phase motor: one motor for the conveyor, one for the roller, and 0.5 kW for the vibrator motor.

The combination of dual electric and high-power motors provides strong power. The built-in thermal protector prevents the motor from overheating and burning. The whole machine runs more stably, has high efficiency and energy saving, and can work continuously for 12 hours without pressure. - Hopper

Thickened material, more durable. Reasonable design, smoother feeding; vibration assistance, suitable for large-scale factories and mines, high output, high efficiency, and long-term work. - Driveshaft

Reasonable design, easy operation, and prolong the life of wearing parts. - Screen

The inclination and length of the drum depend on the screening accuracy; the extended drum screens fine sand and fine powder cleanly, avoiding the problem of incomplete slag screening. - Rebar Drum

The drum (single drum, multi-layer drum) supports customization and steel bar welding.