Tailings Dry Stacking

Dry stacking has been a new tailings processing method in recent years. Dry Stack Tailings (DST) systems are particularly suited to mining operations operating in areas where water conservation is critical. They also provide significant safety and other environmental benefits. There are two main forms of tailings dry stacking: the filter press dehydration process and the thickener dehydration process. Dry stacking is also divided into pure dry stacking and paste stacking.

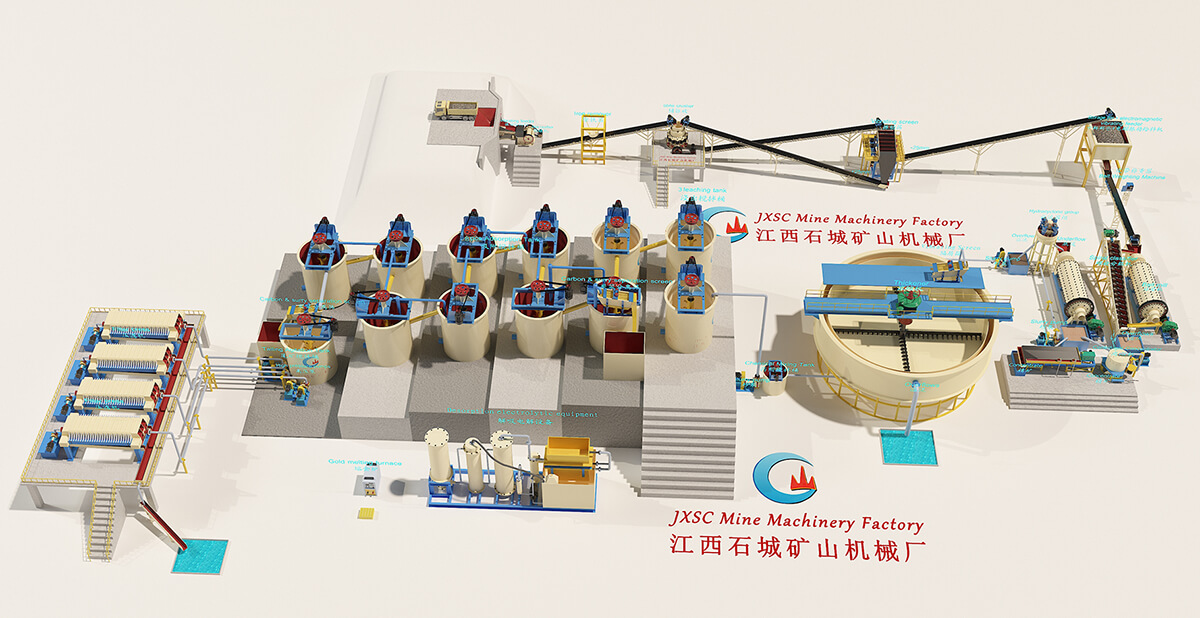

Tailings Dry Stacking Plant

Introduction

About Tailings Dry Stacking

Tailings dry stacking is a method of tailings management commonly used in mining or metallurgical sites. Large tailings are generated during mining and metallurgical processes, which may contain hazardous substances such as heavy metals and chemicals. Tailings need to be treated and managed to reduce environmental impact.

Dry stacking has been a new tailings processing method in recent years. After the multistage concentrating, the tailings pulp is sent to a series of highly efficient dewatering equipment, and slag with low water content, which is easy to cure and store, is formed. The slag can be used as building materials or transferred to a fixed location for dry storage. The tailings dry stacking technology can relieve the capacity pressure of tailings pond storage, reduce the safety hidden danger of tailings pond, and increase the means of tailings reprocessing and tailings processing technology to realize the green mine.

Advantages of dry stack tailings

- Improve structural stability of material storage

Dry stack tailings storage has been found to greatly improve the structural stability of the material stored, especially in high seismic-rated zones, near high population centers, or susceptible environmental areas. - Maximum recovery of recycled water

In the world’s most arid regions, dry stack tailings permit the recovery of the maximum amount of recycled water. The increased recycled water use can significantly lower highly regulated and scarce water sourcing costs. - Recovery of residual process chemicals

Dry stack tailings also promote the recovery of residual process chemicals that can be recovered from recycled water. - The most effective physical storage

Especially in locations with limited available space, dry stack tailings offer the most effective physical storage. The dry stack tailings minimize permitting complexity and the potential of public concerns from nearby communities.

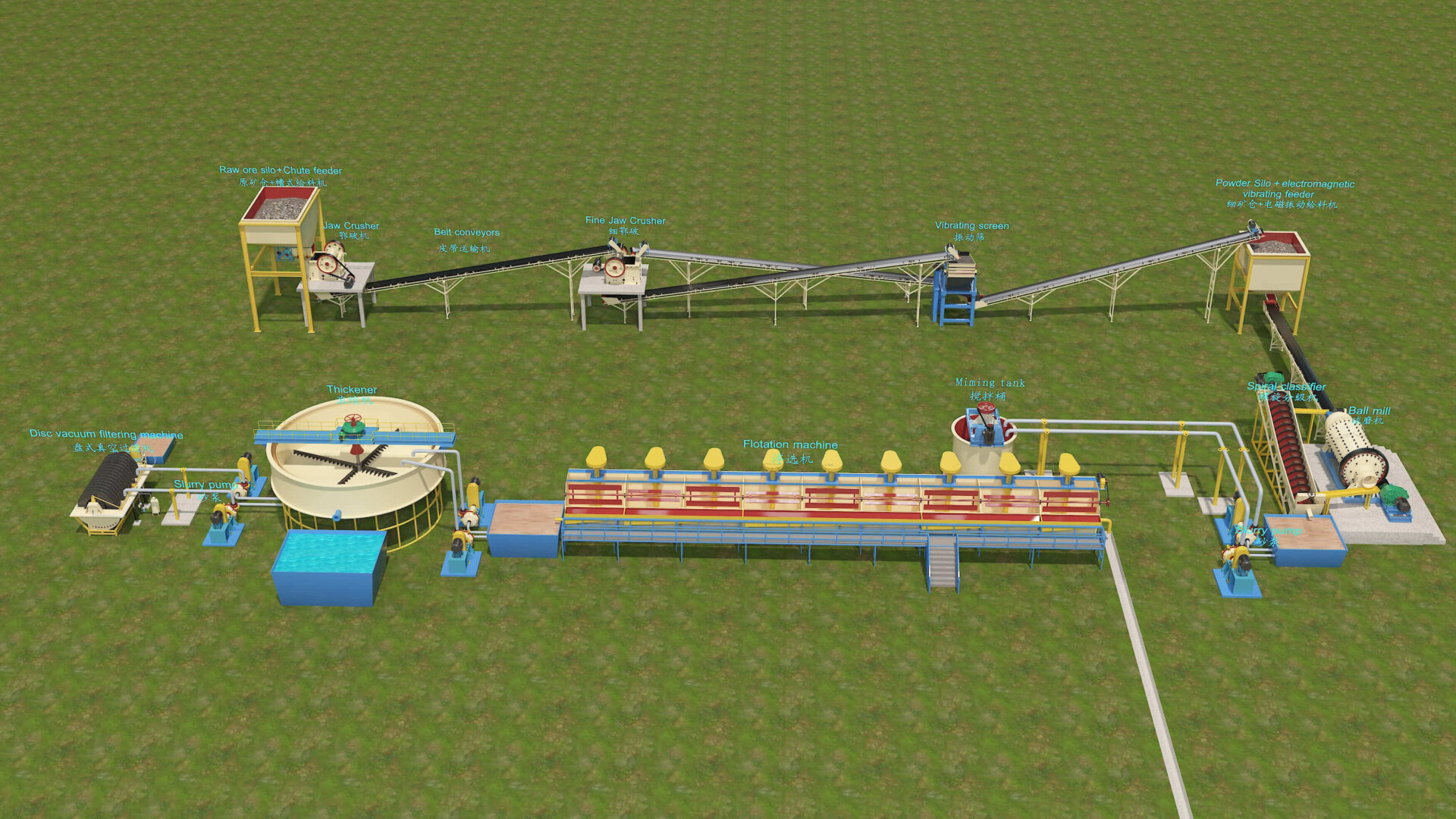

Mineral Processing

Tailings Dry Stacking Processing

The tailings dry stacking processing mainly comprises a slurry pump, hydrocyclone, efficient improved thickener, high-frequency dewatering screen, filter press, and slurry conveying device.

The tailings are transported to the hydrocyclone for concentration and classification by the slurry pump, the sand setting of the hydrocyclone enters the high-frequency dewatering screen for dehydration, and the overflow enters the efficient improved thickener for concentration. The coarse tailings treated by the high-frequency dewatering screen are transported to the material yard for stockpiling by the belt conveyor. Among them, after being concentrated by the efficient improved thickener, the tailings are transported to the filter press by slurry pump for filtration, and the filter cake of the filter press is self-discharged to the belt conveyor. The fine tailings are transported to the material yard for storage.

Tailings Dehydration Process

- Tailings Process With Hydrocyclone

As a device that uses centrifugal force for solid-liquid separation, the hydrocyclone has the characteristics of a small footprint and high underflow concentration. This concentration process mainly uses hydrocyclones and thickeners to form a series or closed-circuit process to obtain high concentrations of a concentrated product. - Tailings Filtration Process With Filter Press

Filter press dehydration is also used in the tailings treatment of gold mines. This method has the characteristics of low moisture content in the filter cake, and the filtrate can be returned for use. However, due to the low processing capacity of a single machine, it is difficult to use it alone to dehydrate large-scale ore dressing tailings.

Dry Tailings Processing Plant

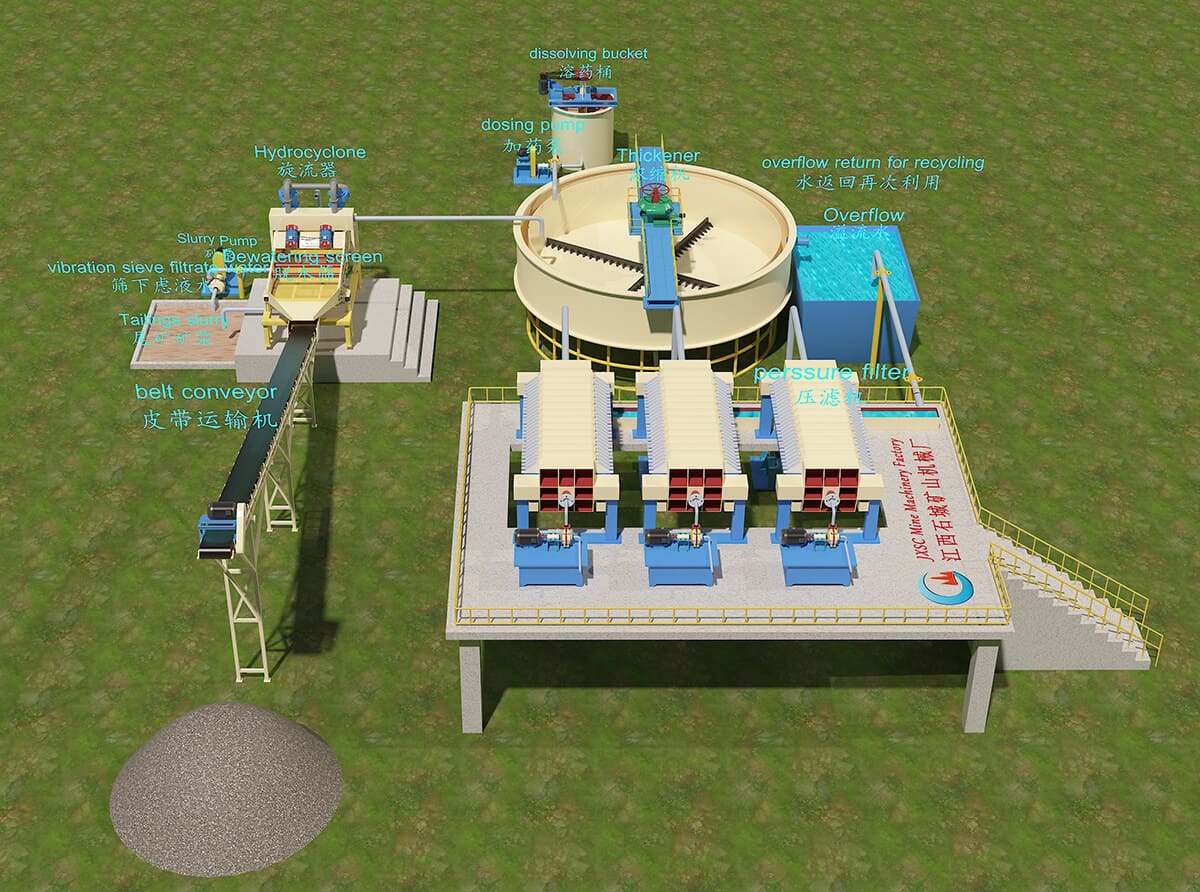

20TPH Dry Stacking Tailings Process Plant

The main configuration includes the dewatering screen, hydrocyclone, thickener, dissolving tank, filter press, belt conveyor, and related pumps.

The process is as follows:

- The tailings slurry pump to the hydrocyclone of the dewatering screen, and the underflow goes to the screen for dewatering. A belt conveyor transfers the oversized product away; the vibration sieve filtrates water and goes to the tailings slurry pool as a closed circle.

- The overflow of the hydrocyclone goes to the thickener for precipitation.

- A flocculant will also be added to the thickener. First, the flocculant will be put into a dissolving tank and pumped into the thickener by a dosing pump.

- The overflow from the thickener for recycling; the underflow from the thickener goes to the filter press.

- The filter press for filtering, the water can be re-used, the solid is dry enough and can transfer away by belt, etc.

The capacity can be customized as per request, such as 10tph, 50tph,50tph, etc.,