Dewatering Screen

Capacity: 10-250t/h

Motor Power: 2.2Kw-30Kw

Screening Sieve: PU screening sieve

Screening sieve hole size: 0.2-0.5mm

Dewatering Screen Overview

Dewatering screen, the main function is dehydration, de-sludge, de-medium, can be used for sand washing in sand and gravel plant, coal slurry recovery in the coal preparation plant, dry discharge of tailings in the mineral processing plant, etc., so it is also called sand and stone dewatering sieve, mining dewatering sieve, slime dewatering screen, tailings dewatering screen, etc.

The high-frequency dewatering screen is multifrequency with large capacity and full dehydration. It adopts a method of drilling holes on the side of the sieve plate, allowing part of the water to flow out of the hole quickly, speeding up the dehydration speed, and also avoiding the damage caused by water splashing on the motor.

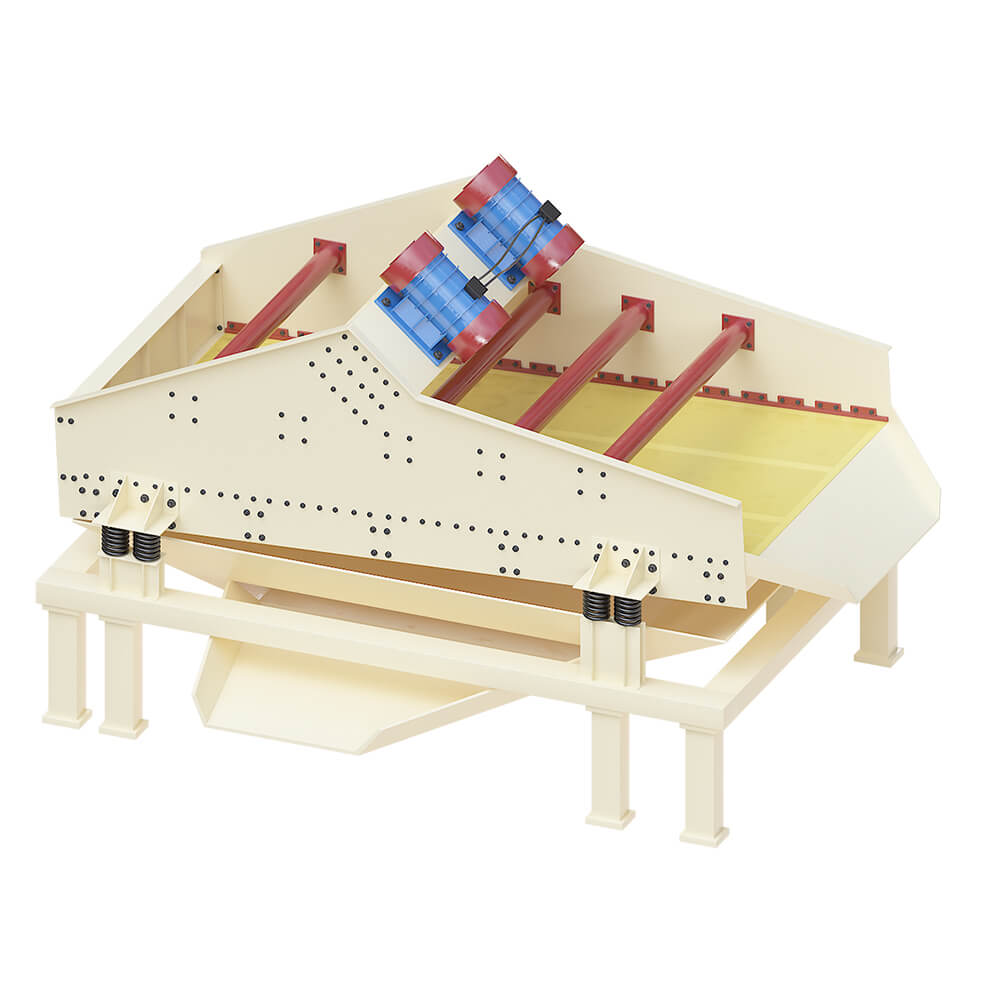

Custom High-frequency Dewatering Screen

The layer of the screen can be a single layer or multilayer. The screen material is usually chosen PU, but you can choose the other material according to your need.

Advantages

Dewatering Screen Advantages

- High efficiency, strong vibrating force and large capacity.

- Simple structure and easy operation and maintenance.

- 45° angle install increases the dewatering area.

- Vibrating frequency is adjustable to meet different ores.

- Torsional shear type high strength bolts are used between side plates and beam, no welding gap that avoids side plates cracking during vibrating.

- Polyurethane screen with better elasticity and fewer blocks. The PU side-push plates protect the equipment from the rushing material and guard the long life of the whole device.

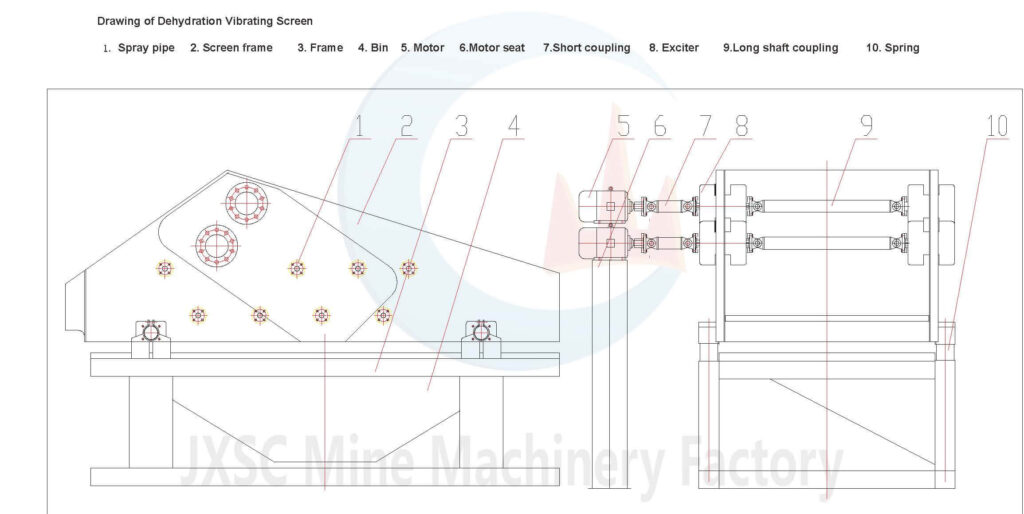

Structures & Working Principle

Dewatering Screen Structure

Dewatering Screen Working Principle

The product adopts a double vibration motor as a power supply: The two motors rotate synchronously and reversely and centrifugal force is produced by two groups of eccentric block. This makes the screen body periodical to-and-fro moving along the direction of a straight line, which is for dehydration. The screen frame is connected by high-intensity bolts, so the structure is stable and durable.

Technical Parameters

| Model | JXSC-1036 | JXSC-1236 | JXSC-1536 | JXSC-1545 | JXSC-1836 | JXSC-1845 | JXSC-2045 | JXSC-2460 |

| Capacity (t/h) | 10-15 | 18-65 | 30-90 | 30-90 | 40-120 | 40-120 | 60-160 | 80-250 |

| Screening Surface Size (mm) | 1000*3600 | 1200*3600 | 1500*3600 | 1500*4500 | 1800*3600 | 1800*4500 | 2000*4500 | 2400*6000 |

| Sieve Size (mm) | Customized according to customer requirements | |||||||

| Double Amplitude (mm) | 0-5 | 0-5 | 0-5 | 0-5 | 0-5 | 0-5 | 0-5 | 0-5 |

| Power (kw) | 2*1.1 | 2*2.2 | 2*3.7 | 2*5.5 | 2*5.5 | 2*7.5 | 2*11 | 2*15 |

| Voltage (v) | 380 | 380 | 380 | 380 | 380 | 380 | 380 | 380 |