Gold Centrifugal Concentrator

Capacity: 0-60 tph

Feeding Size: 0-6 mm

Process Material: Alluvial gold, rock gold after grinding, and other precious metals6

Gold Centrifugal Concentrator Overview

The Gold Centrifugal Concentrator is a brilliant gravity separation equipment widely used in the mining industry, especially for placer gold, fine-grain rock gold, and other precious minerals.

Gold Centrifugal Concentrator Types

- Timed automatic discharge centrifuge, customizable, higher efficiency, higher price.

- Non-automatic discharge centrifuge, common use, in stock, manually stops working and takes out the gold concentrate after a few hours of operation. We have it both in industry type and laboratory type small centrifuge.

- We customized fixed centrifugal and mobile concentrators (mobile gold wash plant usually equipped with portable trommel screen, portable gold centrifuge, portable gold shaker table, etc).

The gold centrifugal concentrator is used in combination with the vibrating chute, gold shaker table, gold wash plant, and other gold extraction equipment to increase the fine gold recovery rate.

Advantages

Gold Centrifugal Concentrator Advantages

- High recovery and high concentrating ratio.

- Center discharge design that enables fast and secure concentrate removal.

- Eco-friendly ( needs no reagents or chemical additives).

- Low energy, low water consumption.

- Durable wear parts with easy maintenance.

- Fast returns on investment, usually less than 6 months.

Structures & Working Principle

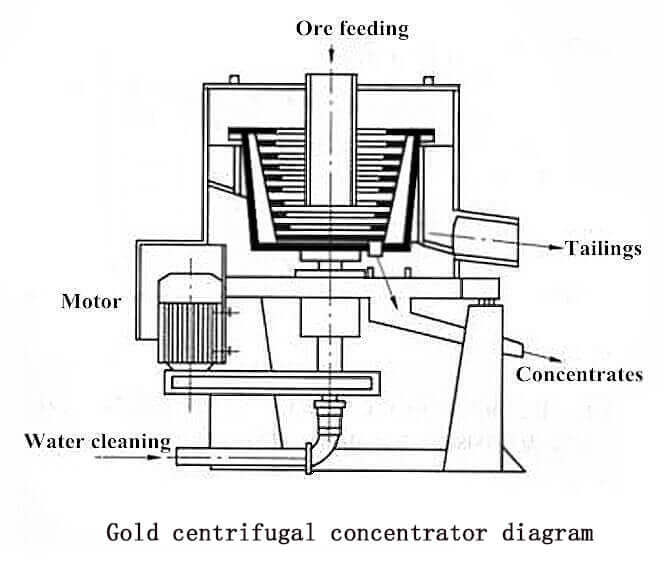

Gold Centrifugal Concentrator Structure

The main parts of a centrifugal concentrator are Feeding, rotor, groove, motor, backwash water, PU lining plate, bearing, frame, tailings concentrate discharge, etc.

Gold Centrifuge Principle

The rotor of the centrifuge rotates at a high speed. Under the action of centrifugal force, heavy minerals are stacking on the inner plate groove of the rotor core, and the light ore particles are gradually discharged. After about 4-6 hours of operation, stop feeding, and turn on the backwater to wash out the gold concentrate.

Gold centrifugal concentrator is useful in the gold recovery in all ranges of particle size. It is most especially useful for recovering fine gold which gets lost during the operation of gravity concentrators. The application has shown that the recovery of gold can be very high, as much as 99% and the concentration ratio is up to 1,000 times. In the recovery of natural gold in lode ore that has a particle size of -0.074mm, the gold recovered is about 98%, for recovery of gold in particle size of 0.004mm, it is up to 97%.

Technical Parameters

| Model | Capacity (T/H) | Feeding Size(mm) | Feeding Density(%) | Power (kW) | Cone Rotate Speed (RPM) | Back Water Required(m3/h) | Dimension(mm) |

| STLB20 | 0.5-1 | 0-2.5 | 20-50 | 1.1 | 800 | 15 | 800*560*710 |

| STLB30 | 2-3 | 0-4 | 20-50 | 2.2 | 600 | 20 | 1280*1030*1135 |

| STLB60 | 8-12 | 0-6 | 20-50 | 7.5 | 460 | 50 | 1850*1550*1600 |

| STLB80 | 10-20 | 0-6 | 20-50 | 15 | 400 | 80 | 2300*1800*2200 |

| STLB100 | 40-60 | 0-6 | 20-50 | 18.5 | 360 | 100 | 2400*2400*2250 |