Molybdenum Mining

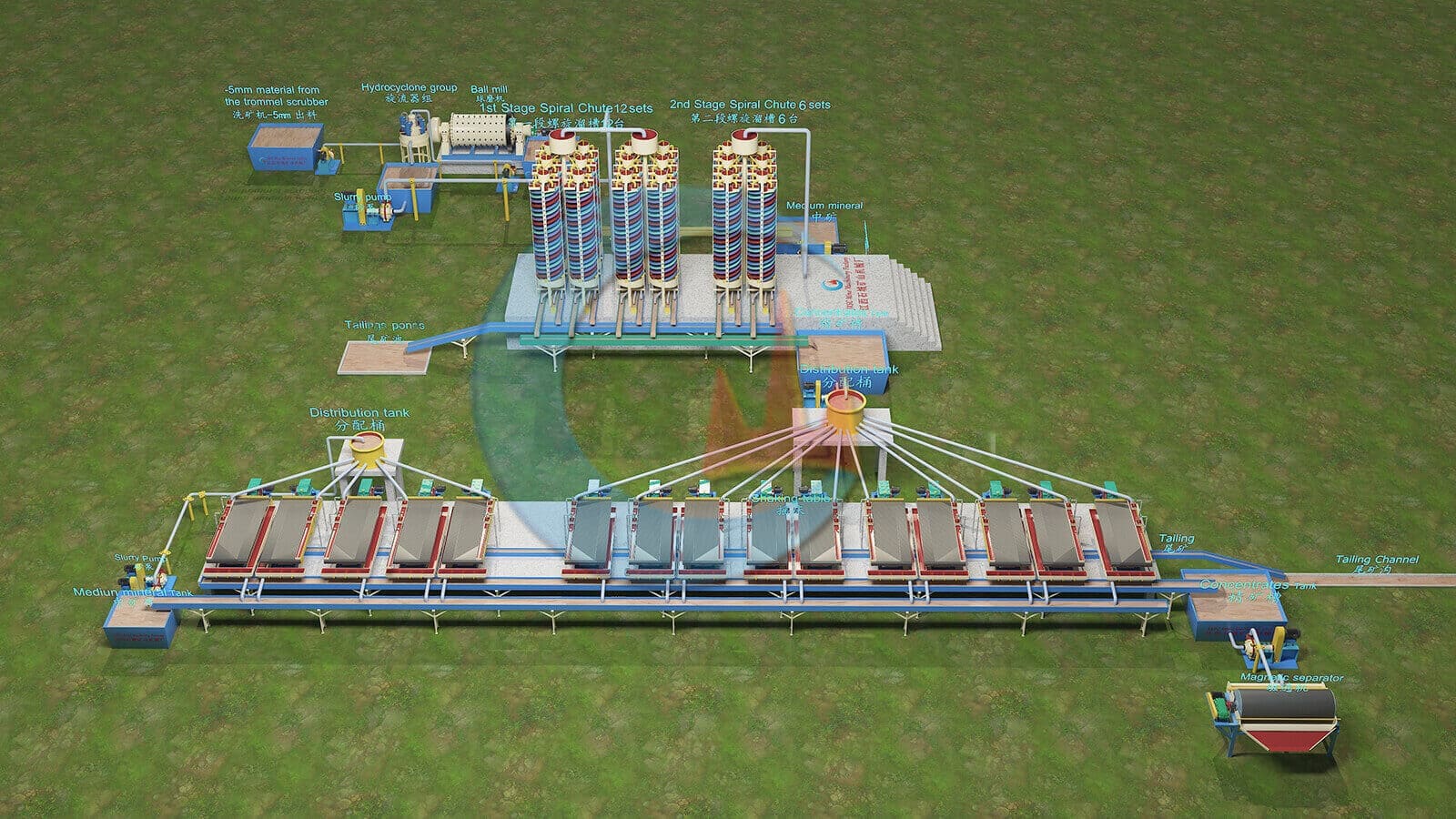

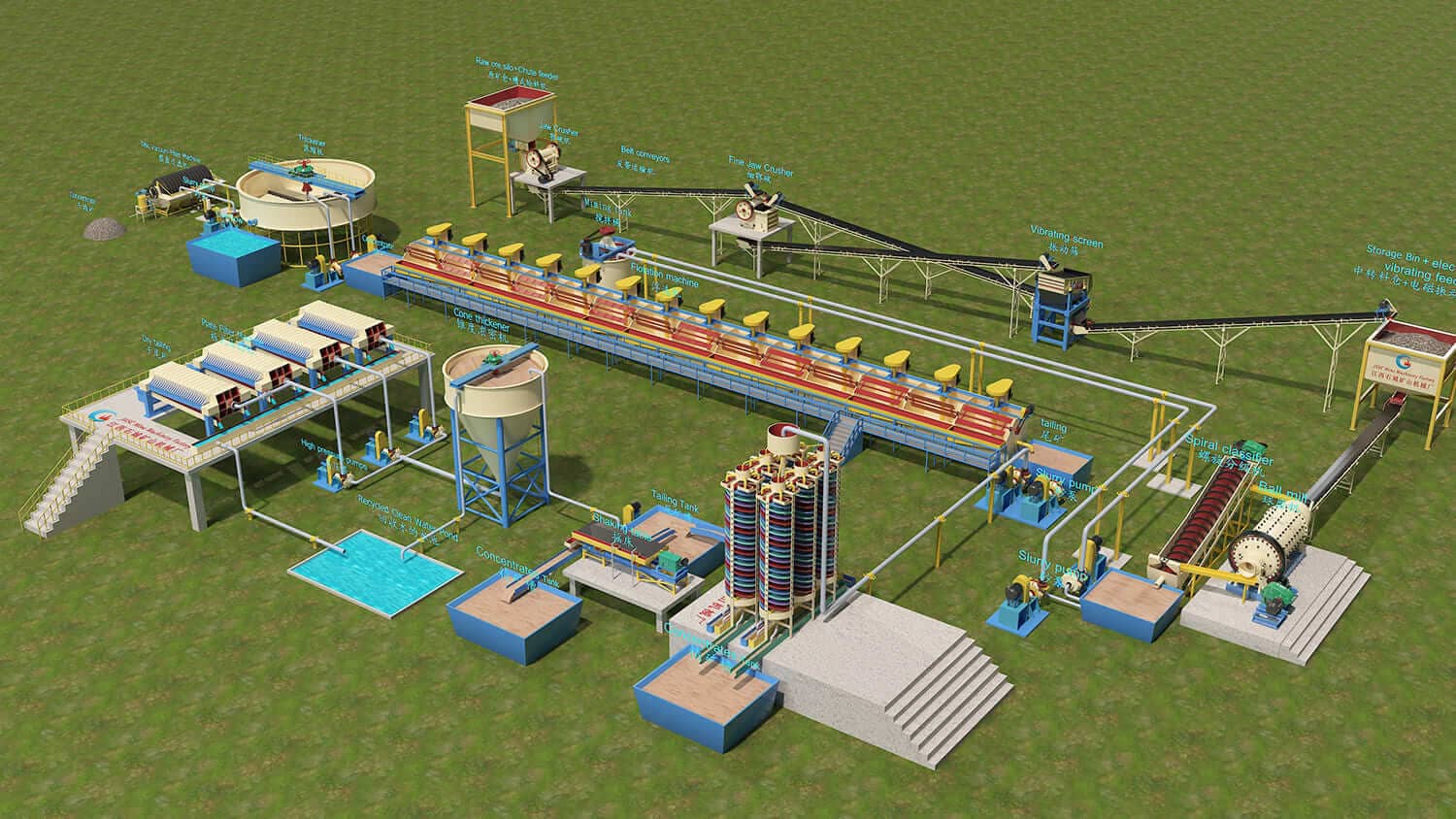

The primary beneficiation method for molybdenum ore is flotation, and the recovered molybdenum mineral is molybdenite. Sometimes to improve the quality of molybdenum concentrate and remove impurities, the molybdenum concentrate is subjected to chemical beneficiation. Molybdenum ore is an essential industrial ore; its main mineral is yellow molybdenum ore (MoS2). The conventional molybdenum ore beneficiation process mainly includes ore crushing, grinding, flotation, and concentration.

Molybdenum Beneficiation

Introduction

About Molybdenum Ore

Molybdenum (Mo) is a metallic, lead-gray element with a density of 10.2 g / cm³, with a high melting point (4,730 degrees Fahrenheit). Molybdenum occurs in nature in chemical combination with other elements. There are various molybdenum-bearing minerals, but the only one of commercial significance is molybdenite (MoS2) – a natural molybdenum sulfide. The most important ore source of molybdenum is the mineral molybdenite.

Molybdenum Ore Types

Based on the minerals contained in ore bodies and their quality, molybdenum ore is divided into three categories:

- Primary ore: The molybdenite recovery is the only goal;

- By-product ore: In which the recovery of copper ore is the main target, molybdenum recovery provides additional economic value;

- Symbiotic product ore: The commercial viability of the mine requires that both molybdenite and copper-bearing minerals be recovered.

Mineral Processing

Molybdenum Processing

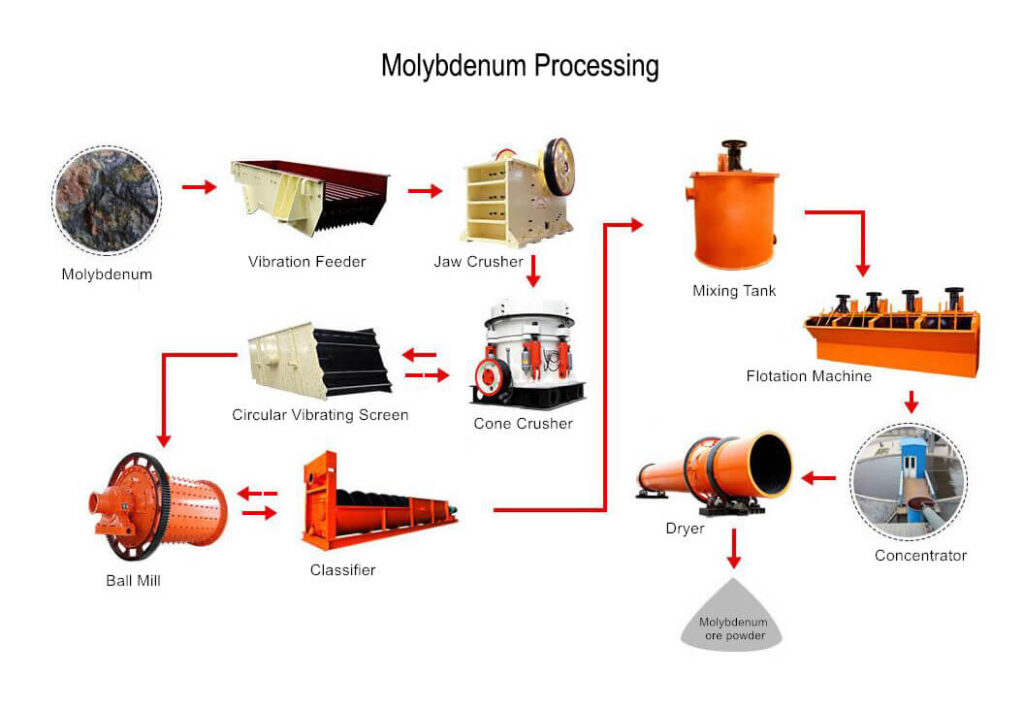

Molybdenum ore processing involves several stages to extract molybdenum concentrate, which is further processed to obtain molybdenum metal or other molybdenum compounds. The primary method used for molybdenum processing is the flotation process.

Ore Crushing

The molybdenum ore is initially crushed through a crusher, usually a jaw crusher and an impact crusher. The purpose of crushing is to break down the ore into smaller particles to facilitate subsequent grinding and flotation operations.

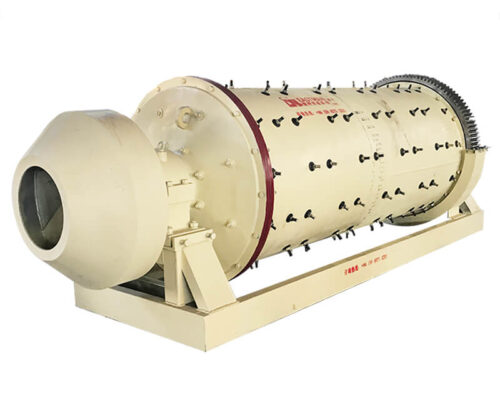

Grinding

Send the crushed molybdenum ore into a ball mill for grinding. Grinding aims to refine the ore particles further, increase the contact area between molybdenum ore and chemicals, and promote the improvement of the flotation effect.

Flotation

Molybdenum flotation generally adopts a multi-stage flotation process. First, the ground ore slurry is sent to the rougher, and through mechanical stirring and air blowing, the molybdenum-containing minerals and flotation agents are adsorbed, causing them to float on the surface of the slurry to form bubbles; then, The floating bubbles with adsorbed molybdenum minerals are collected by a scraper; finally, the collected floating bubbles containing molybdenum are selected and selected further to improve the grade and recovery rate of molybdenum.

Concentration

By adding chemicals and adjusting flotation conditions, the molybdenum ore and flotation foam are adsorbed more firmly, increasing the molybdenum concentration. Press filtration or centrifugal separation is usually used to separate the concentrated flotation foam from non-flotation materials to obtain molybdenum concentrate with higher purity.

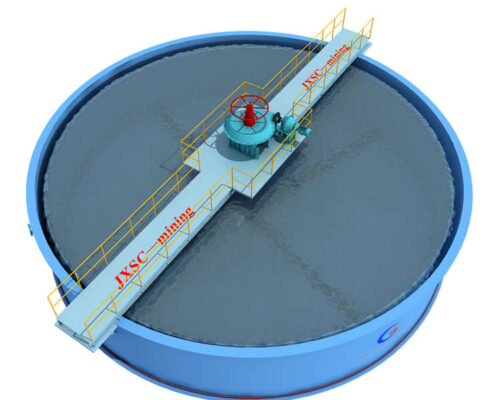

Concentrate Drying

The molybdenum concentrate slurry, after flotation treatment, first enters the concentrator for high-efficiency concentration and precipitation and then is thoroughly dried by the dryer to obtain the finished molybdenum concentrate powder.