Silver Extraction Process

There are various methods of beneficiation of silver ore, mainly including flotation, gravity separation, cyanidation, and leaching. According to the different properties of silver ore, the required mineral processing processes are also different. Independent silver ore beneficiation methods usually use flotation to beneficiate silver, while co- and associated silver ores use a single flotation method and a combined process of flotation-gravity and flotation-cyanidation, among which flotation is more commonly used.

Silver Extraction Plant

Introduction

About Silver Ore

Minerals rich in silver are called silver ores. Pure silver is silvery white, so it is also called silver. Silver has the highest electrical and thermal conductivity, good ductility and plasticity, is easy to polish and shape, and can form alloys or pseudo-alloys with many metals.

Silver Ore Types & Beneficiation Methods

- Silver ore containing a small amount of sulfide minerals: Silver is the only useful component that can be recovered. The sulfide minerals are mainly pyrite, with few other associated components with recovery value. This type of ore is often called a single silver ore. This type of ore can be beneficiated by flotation and cyanidation.

- Silver-containing lead-zinc ore: The silver, lead, and zinc in the ore can all be recovered and are the main mineral raw materials for producing silver. Use the flotation method to recover silver, lead, and zinc.

- Silver-bearing gold ore or gold-silver ore: In gold mines, silver and gold grow symbiotically, and gold and silver often form alloys, which are called silver-gold ore or gold-silver ores. Use the flotation method to produce gold and silver mineral concentrates and the cyanidation method to make alloy gold or gold and silver ingots.

- Silver-containing copper sulfide ores: Copper sulfide ores in various countries contain a small amount of silver, and silver is closely symbiotic with natural gold and copper sulfide minerals. Recover gold and silver using the flotation method.

- Silver-containing diamond ore: Silver exists in calcite, symbiotic with arsenopyrite and orthogonal iron ore in some diamond ores. This type of ore is rare, and the mineral processing process is more complicated.

- Silver-containing sharp ore: Useful components such as silver and lead can be recovered from this type of ore.

Mineral Processing

The simplest methods for refining silver ore mainly include flotation, gravity separation, cyanidation and the combination of these methods.

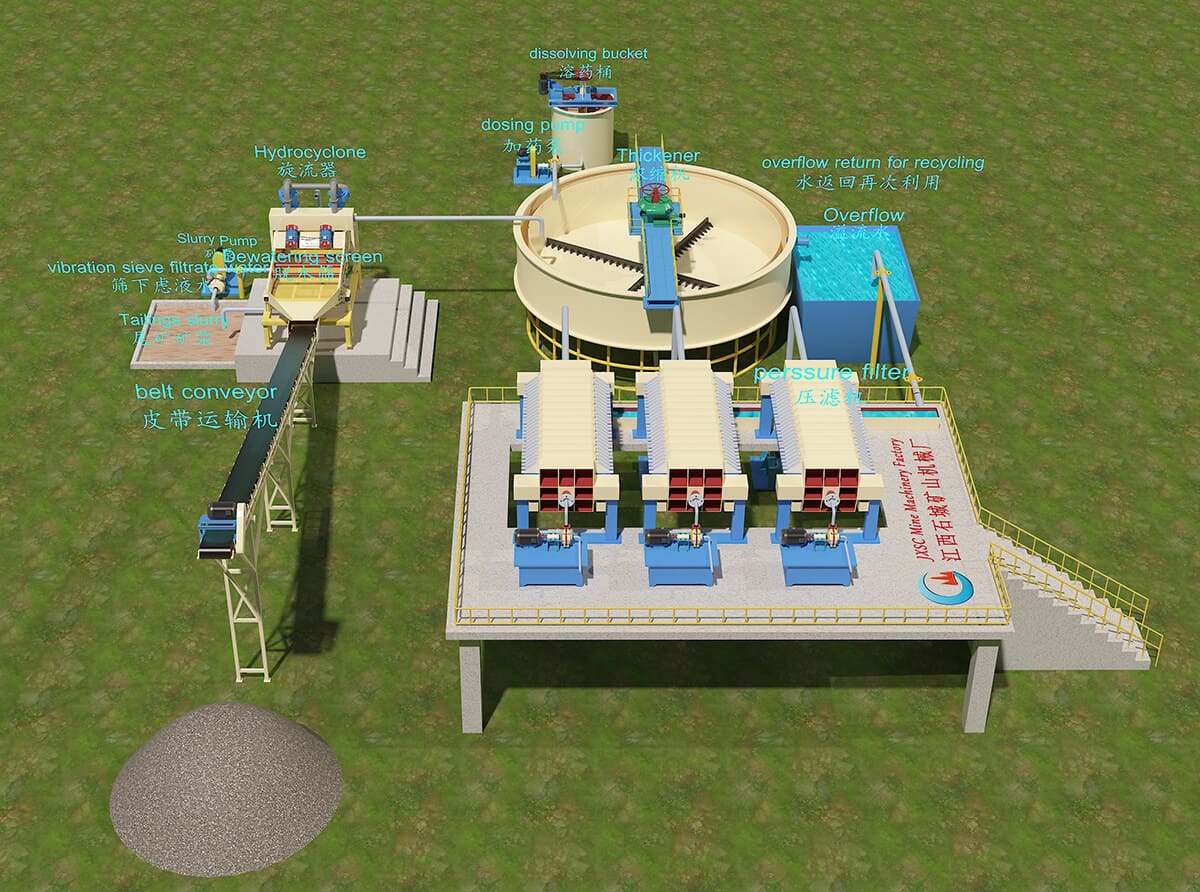

Silver Ore Cyanidation

The cyanidation process is suitable for the treatment of silver-containing sulfide ores.

The process is as follows:

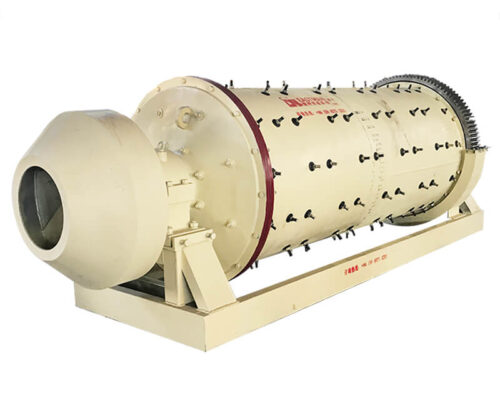

Crush and grind the silver-containing ore to an appropriate particle size. Send to with a sodium cyanide solution for reaction, and dissolve silver. Take the silver-containing solution from the leach tank or reactor and recover the silver by precipitation, immobilization, and electrolysis. After these steps, extract silver from silver-containing sulfide ores using cyanidation.

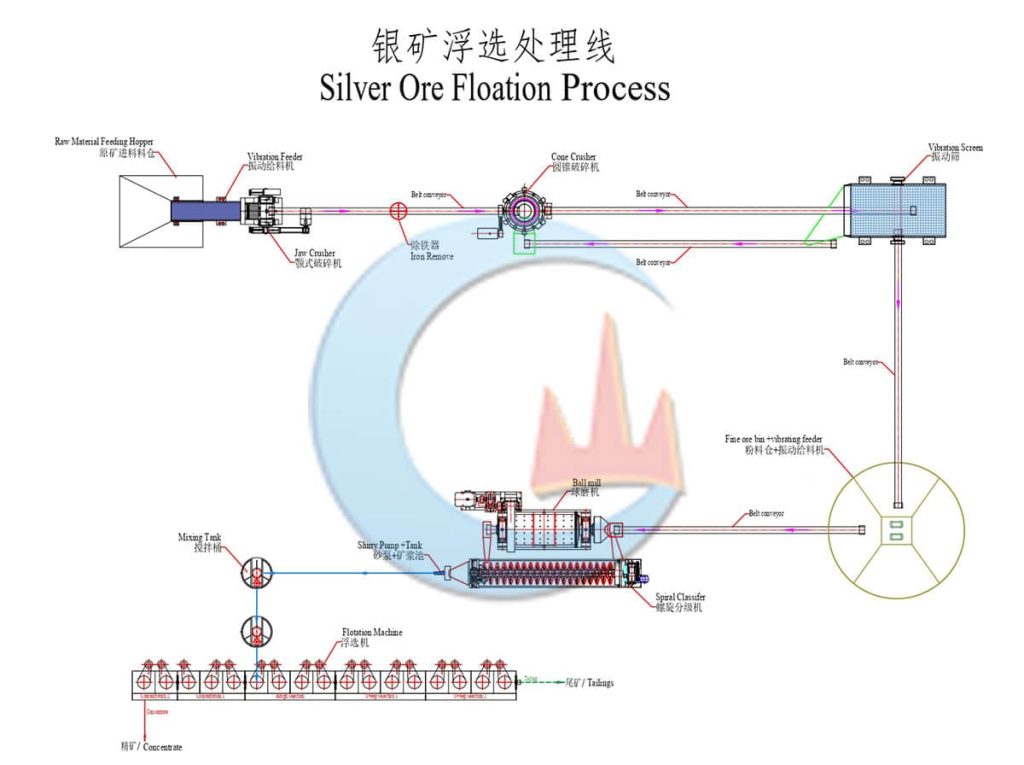

Silver Ore Flotation

Flotation is the primary method for recovering associated silver. It deals with fine-grained silver and silver minerals that are closely symbiotic with sulfide ores. Except for coarser silver, it can almost recover all monomer dissociated silver, and the silver mineral process is simple and compact; the tailings are generally non-toxic.

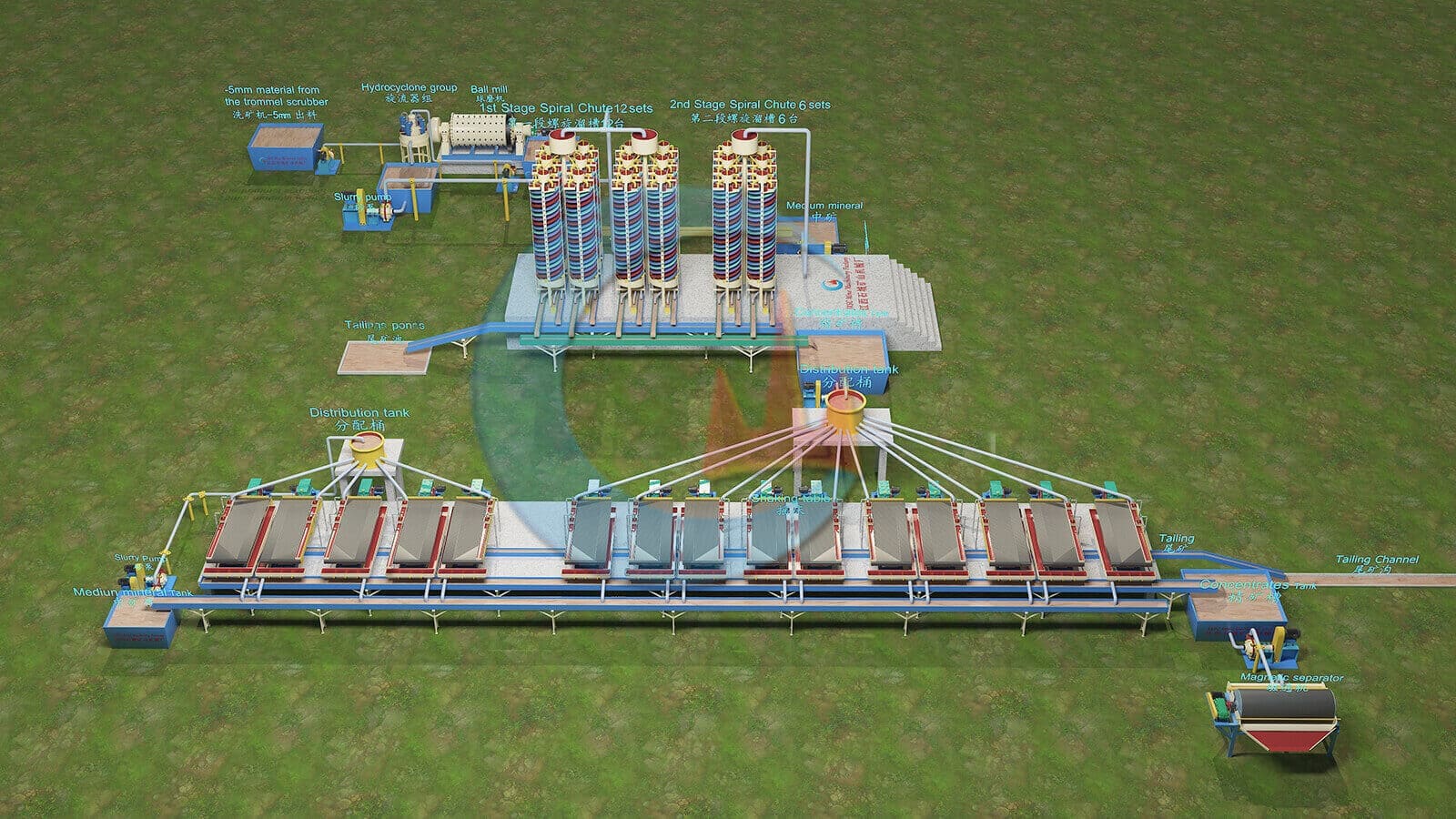

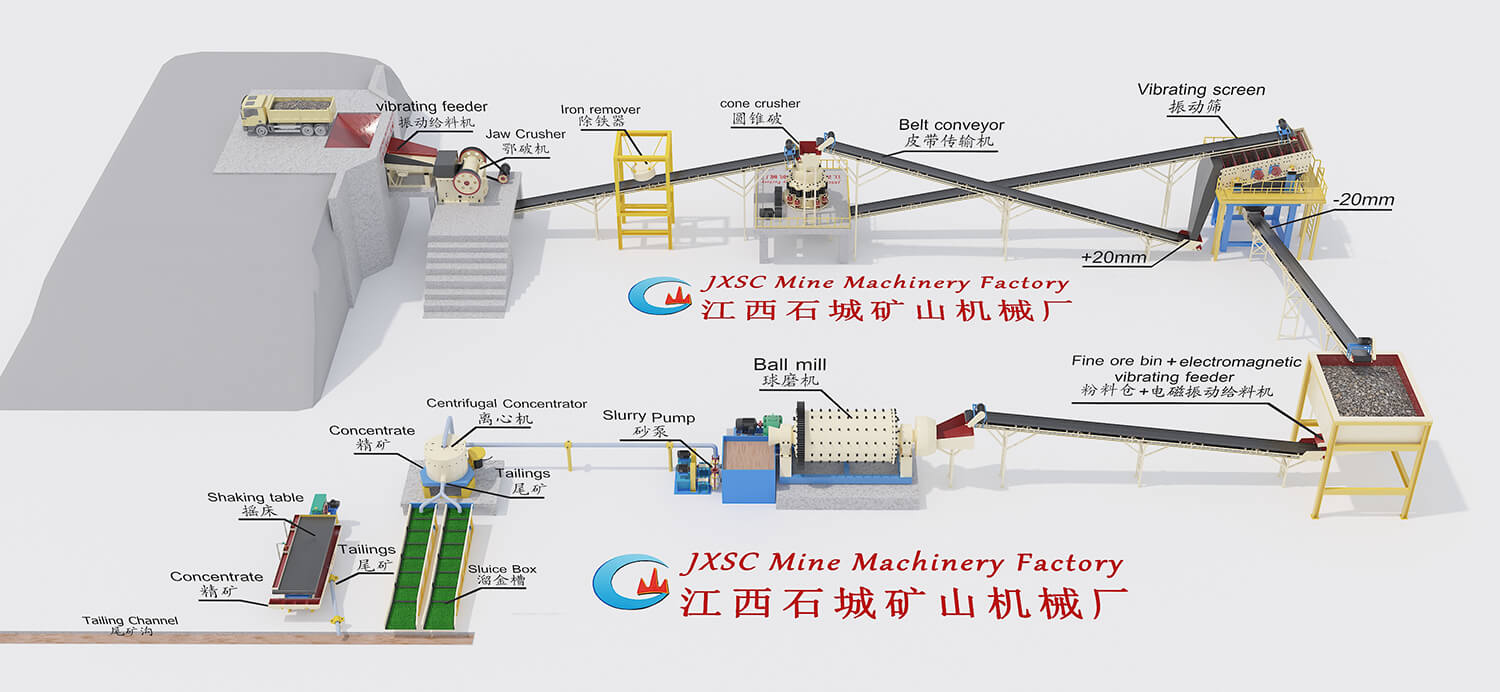

Silver Ore Gravity Separation

The gravity separation processes monomer dissociated silver ore(silver with coarse particle size and existing in a free state). It includes Nelson centrifugal concentrator, hydrocyclone, heavy medium pre-selection, jig separator, shaker, spiral classifier, etc. There is no pollution when recovering silver by gravity separation, the grinding particle size is coarse, and the grinding cost is low. The disadvantage is that the silver recovery rate is low and the water consumption is large, so flotation is often used with gravity separation.