Gold Carbon-in-pulp(CIP) Process

Gold carbon-in-pulp(CIP) is a typical gold beneficiation process for the effective recovery of gold-bearing minerals with a high oxidation degree and low grade of raw ore. Gold CIP has become a widely used gold extraction method worldwide because of its advantages of high adsorption rate, high recovery rate, and low investment cost.

Gold CIP Solution

Introduction

About Gold CIP

Gold CIP is one of the methods of gold extraction by cyanidation. It is a carbon adsorption process of monovalent gold cyanide [KAu(CN)2] after the cyanide leaching of gold-bearing materials.

CIP usually applies in flotation gold concentrate, high argillaceous oxidized gold deposit, mercury mixing, and gravity separation tailings.

Mineral Processing

CIP Process

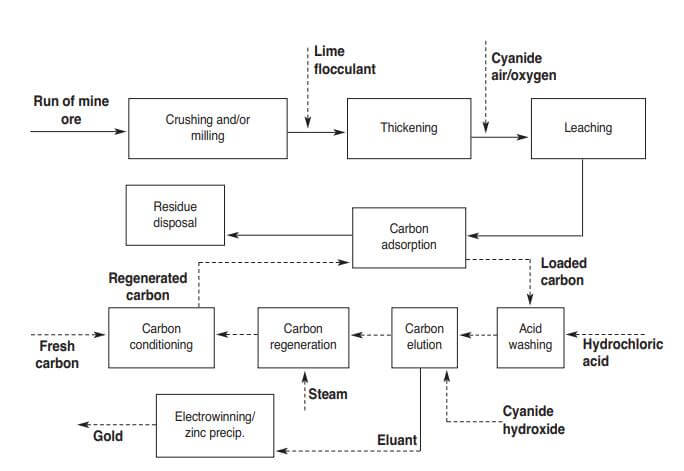

The gold CIP process includes seven operation stages: preparation of leaching pulp, cyanide leaching, carbon adsorption, gold-loaded carbon desorption, electrolysis to obtain muddy gold, de-gold carbon recycling, and treatment of leaching pulp.

- Preparation of leaching pulp

Grind the gold-containing material to a particle size suitable for cyanidation, generally less than 28 mesh. Remove impurities such as sawdust. Concentrate and dehydrate to make the concentration of the leached pulp reach 45%-50%. - Cyanide leaching

The same as the conventional cyanidation method, generally 5-8 mixing tanks. - Carbon adsorption

The cyanide pulp enters the stirring adsorption tank (carbon slurry tank). Add carbon to the leaching tank, and the carbon adsorbs the gold in the pulp to become gold-loaded carbon. After the adsorption is completed, the carbon and the pulp are separated by a carbon extraction screen. - Gold-loaded carbon desorption

In a closed system, gold-loaded carbon can be rapidly desorbed and electrolyzed into gold mud and lean carbon under high temperature and high-pressure conditions. Four methods are currently available for Desorption:

① Hot caustic sodium cyanide solution desorption.

② Low concentration caustic sodium cyanide solution plus alcohol desorption.

③ Desorption with acidic sodium cyanide solution under heating and pressure conditions.

④ Desorption of high concentration caustic sodium cyanide solution. - Electrolysis to obtain muddy Gold

In a closed system, gold-loaded carbon can be rapidly desorbed and electrolyzed into muddy gold and lean carbon under high temperature and high-pressure conditions. It can smelt the obtained muddy gold into gold ingots after simple pickling and impurity removal. - Regenerated carbon

The desorbed lean carbon is first soaked in 1.5% ~ 2.0% nitric acid solution for 24 hours to remove calcium and then washed with clean water until neutral. Return to the adsorption cycle. - Treatment of leaching pulp

A filter press filters the leaching pulp, the slag stacking treatment, and the water is recycled.

Gold CIP 3D Videos

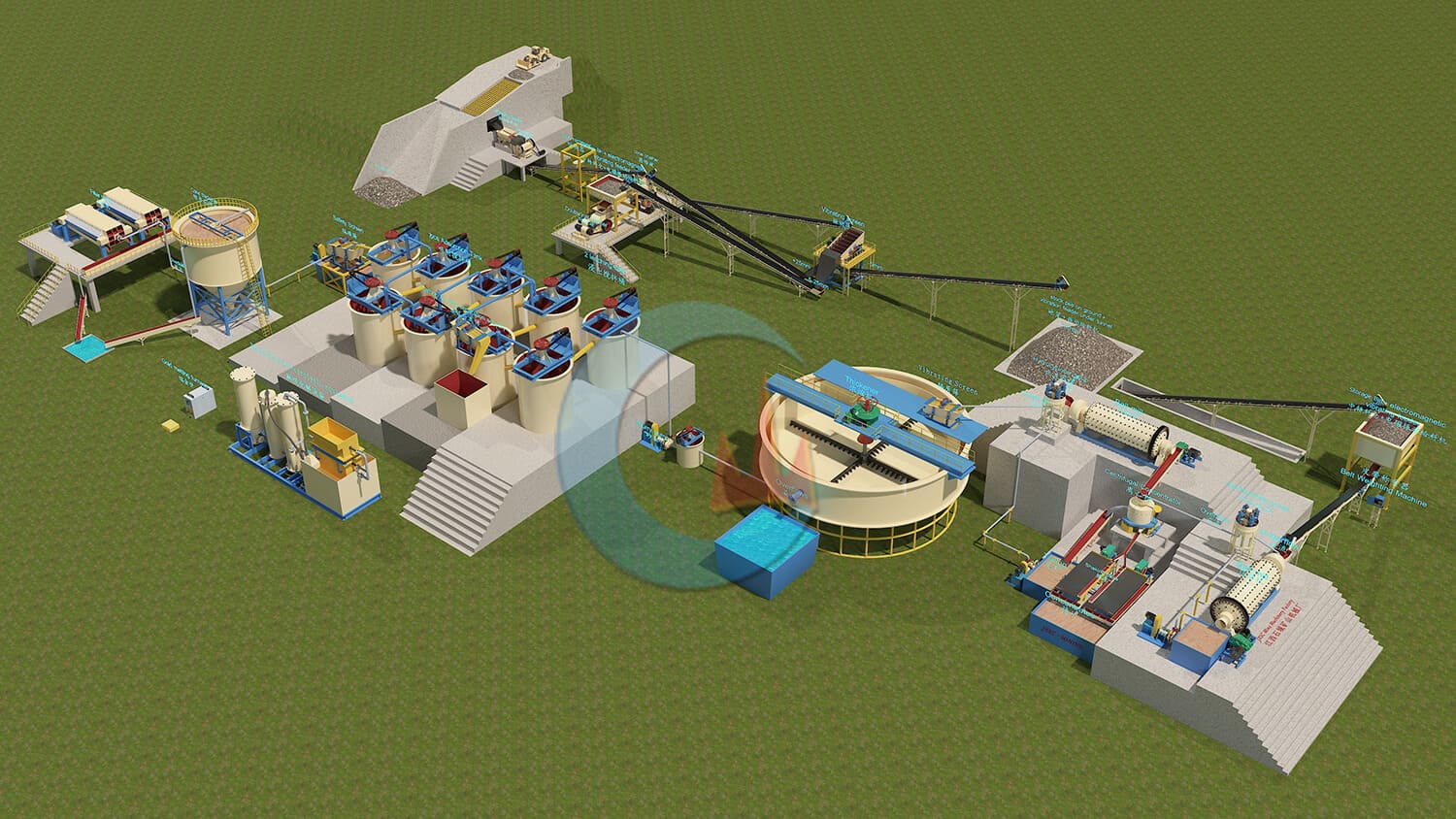

600TPD(25TPH) Rock Gold Gravity Separation & CIP Process Plant

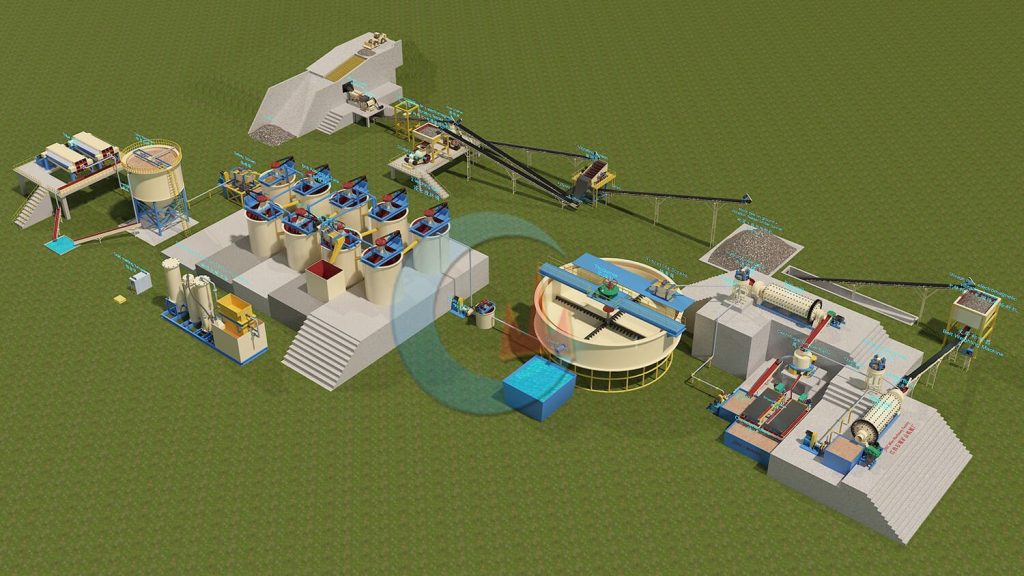

300TPD(12TPH) Complete Gold CIP Processing Plant