Home » Equipment » Gravity Separation Equipment » Jig Concentrator

Jig Concentrator

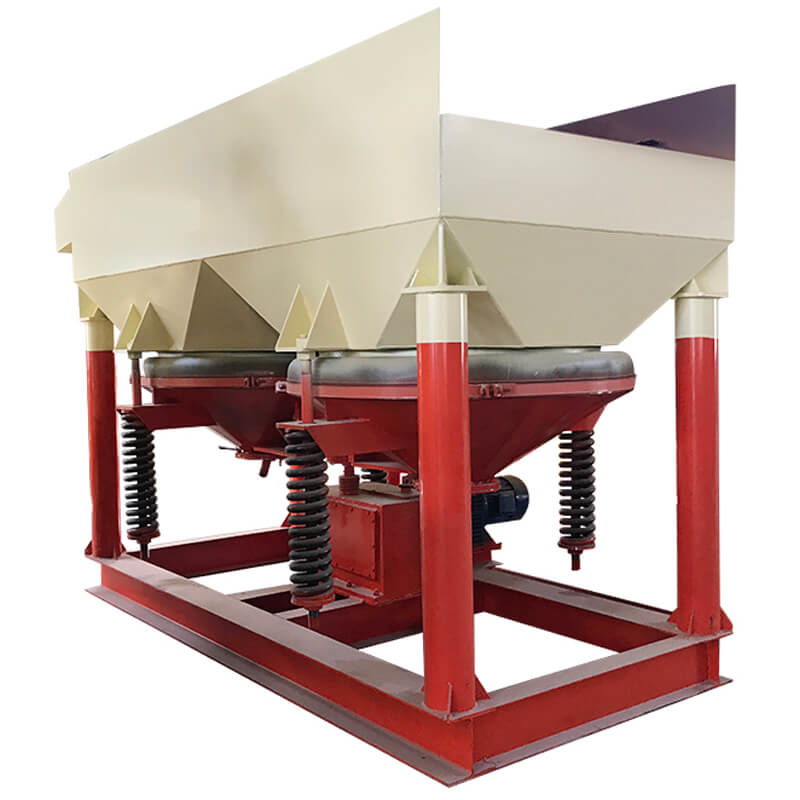

The jig concentrator (or jig separator) is a gravity-based mineral processing machine that separates particles by density using pulsating water flow. It is widely used for coal, gold, tin, tungsten, iron ore, and diamonds, efficiently recovering coarse to medium-sized heavy minerals.

Capacity: 1-25 tph

Feeding Size: <25 mm

Process Material: Alluvial gold, crushed rock gold, coltan, tin, tungsten, diamond, barite, iron, manganese, fluorite, garnet, etc.

Jig Concentrator Overview

The Jig separator concentrator is an effective gravity separation machine based on the ore material density difference. The jigging machine is mainly used for processing placer gold, coltan, tungsten, tin, etc. The higher the density difference, the better the jigging separation effect.

Jig Concentrator Types

- Eccentric jig concentrator (plunger jig separator machine and diaphragm jig separator machine)

- Hydraulic jig separator machine

- Movable sieve jig separator

- Air pulsating jig separator

- Trapezoid jig separator machine

The diaphragm jig separator machine has high beneficiation efficiency and can process coarse particle ore, separate tungsten, tin, and the like with a particle size of up to 16 mm and a minimum particle size of 0.5 mm.

The trapezoidal jig separator machine has a large processing capacity and a wide particle size of 50-0.25 mm. It has been promoted and used in tungsten, tin, and iron ore dressing plants.

According to the beneficiation medium, mineral jig divided into the hydraulic jig and dry jig, dry material feeding has a better result.

Advantages

Jig Concentrator Advantages

The jig concentrator stands out for its efficient and economical operation, requiring significantly less water compared to most centrifugal concentrators, making it ideal for resource-sensitive environments. It delivers exceptional mineral recovery rates, efficiently converting 0.5% to 30% of feed material into high-grade concentrate, maximizing both yield and profitability. Offering wide feed adaptability (up to 30mm particle size), the jig concentrator reduces the need for pre-screening and minimizes over-grinding, optimizing gravity recovery while lowering energy consumption. With its low operating costs, minimal water usage, and high recovery performance, it is a cost-effective and versatile solution for both small and large-scale mineral processing operations.

✔ Wide Particle Size Range(0.5-50mm)

✔ No Chemical Additives(Eco-friendly separation)

✔ Low Energy Consumption(Up to 30 t/h per unit)

✔ High Recovery Rates(85-95% for gold ore)

Structures & Working Principle

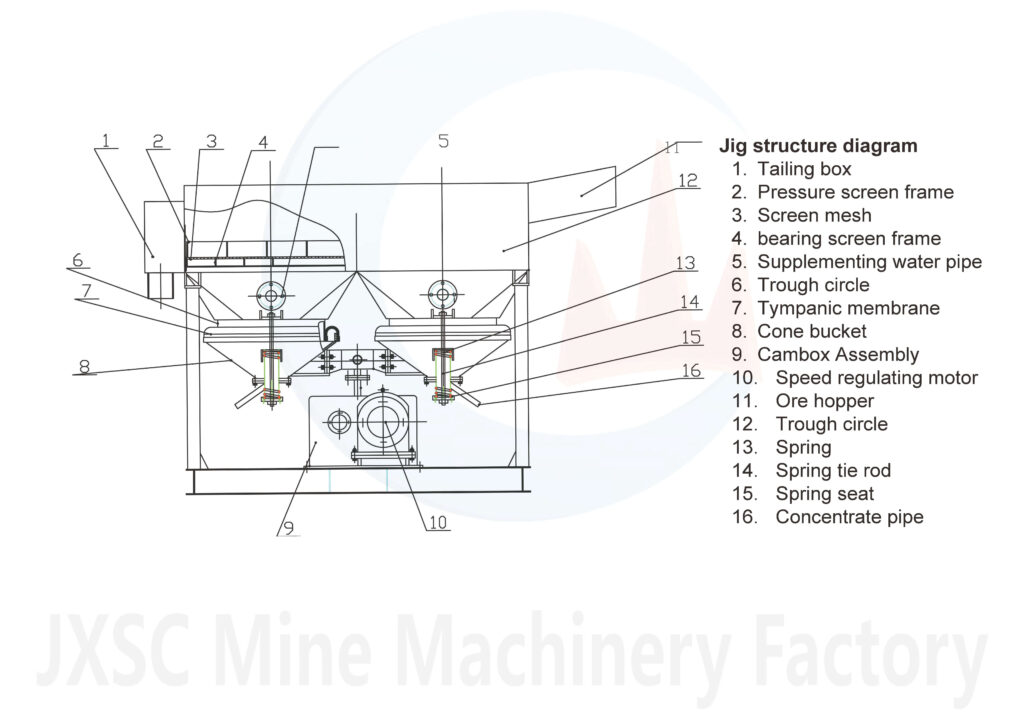

Jig Separator Structure

The main parts of a jig separator are the tailing box, pressure screen frame, screen mesh, bearing screen frame, supplementing water pipe, trough circle, tympanic membrane, cone bucket, cam box assembly, speed regulating motor, ore hopper, trough circle, spring, spring tie rod, spring seat, concentrate pipe, etc.,

Jig Separator Working Principle

The mixture of mineral particles of different specific gravities is layered by specific gravity in a vertically moving variable-speed medium flow (water or air). The ore particles with a small specific gravity are located in the upper layer, and the larger ore particles are located in the lower layer, and then they are separated into products of different specific gravity by mechanical action and water flow, and are respectively discharged.

【Mineral bed】 usually pave a 10-15cm mineral bed by using iron ore ( 50% grade ). JXSC engineer will help you to determine the bed thickness, iron size, screen mesh, and adjust the stroke, stroke frequency before delivery.

Technical Parameters

| Model | Jigging Chamber | Diaphragm | Feeding Size (mm) | Back Wash Water(m3/h) | Back Wash Water Pressure (Mpa) | Capacity(T/H) | Power(KW) | Dimensions (mm) | Weight (T) | ||

| Shape | Jig Area (M2) | Stroke | Jig Frequency | ||||||||

| JT0.57-1 | Trapezoid | 0.57 | 10-17 | 80-120 | <10 | 18-20 | ≥0.1 | 1-3 | 1.5 | 1500*780*1530 | 0.6 |

| JT1-1 | Rectangle | 1.1 | 10-17 | <10 | 20-30 | 2-5 | 2.2 | 2270*1110*1890 | 0.9 | ||

| JT2-2 | Rectangle | 2.3 | 10-17 | 60-100 | <25 | 40-50 | 4-8 | 3 | 2900*1550*2000 | 1.4 | |

| JT4-2 | Rectangle | 4.5 | 20-30 | <25 | 80-100 | 10-15 | 7.5 | 3900*2000*2460 | 3.2 | ||

| JT4-2A | Rectangle | 4.5 | 20-30 | <25 | 80-100 | 10-15 | 4*2pcs | 3900*2000*2460 | 4 | ||

| JT5-2 | Trapezoid | 5 | 20-30 | <25 | 80-100 | 10-20 | 7.5 | 4000*2050*2600 | 3.2 | ||

| JT6-3 | Rectangle | 6.8 | 20-30 | <25 | 120-150 | 20-25 | 7.5+4 | 5400*2000*2460 | 5 | ||