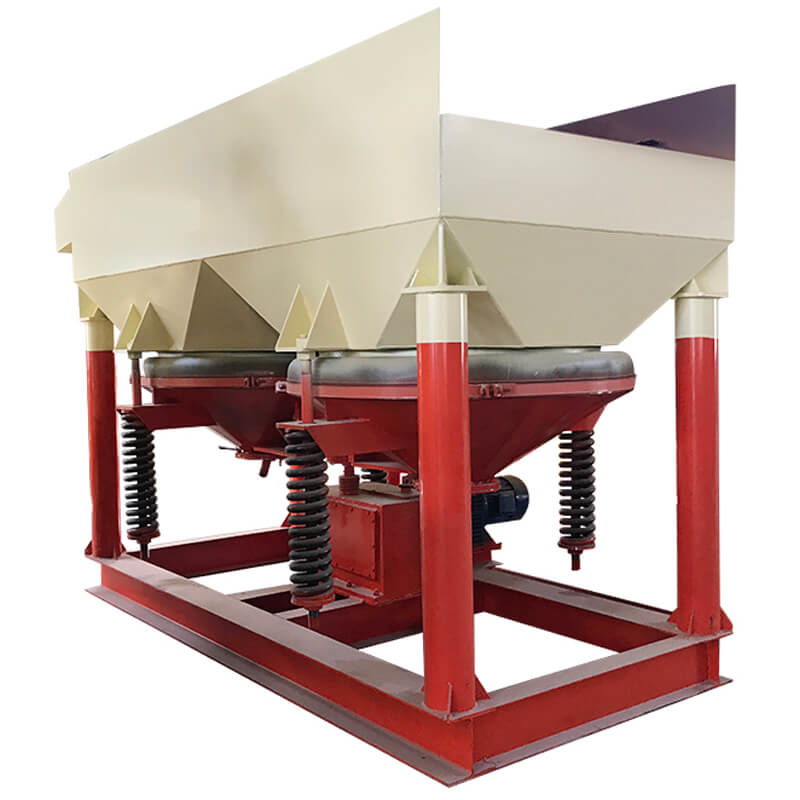

Mobile/Portable Mineral jig Separator Plant

Mineral Jig Separator

A mineral jig separator, also known simply as a jig separator or jig concentrator, is a type of gravity separation equipment used in the mining and mineral processing industry to separate materials based on their specific gravity. It operates on the principle of pulsating water flow combined with gravity to separate heavier particles from lighter ones.

Mineral jig separators are used in various mining operations, especially in alluvial and placer mining scenarios where particles have been naturally sorted by water action. They are also used in hard rock mining to separate valuable minerals from gangue or waste material.

The design and configuration of a mineral jig separator can vary based on factors such as the type of minerals being processed, the particle size distribution of the feed material, and the desired separation efficiency level. Some jig separators use mechanical mechanisms to create the pulsating motion, while others use air pulsation or hydraulic action.

Mineral jig separators are versatile tools that are particularly effective in recovering heavy minerals with a large specific gravity difference from surrounding materials. They are commonly used in gold recovery, diamond recovery, tin mining, and other mineral processing operations.

Mineral Jig Separator Highlights

- Cone Bucket

Long service life, wear-resistant, corrosion-resistant, high-quality steel.

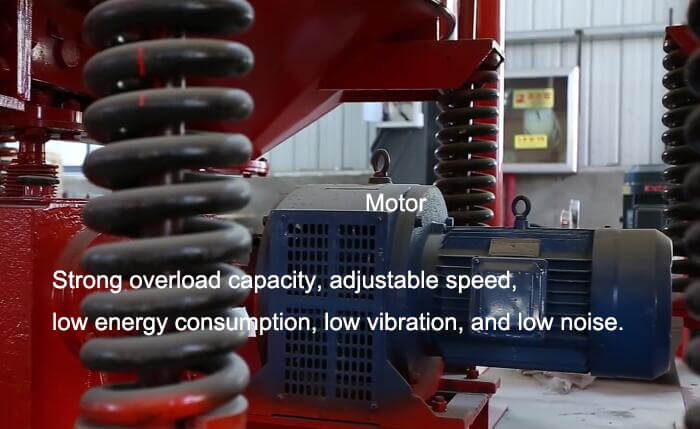

- Motor

Strong overload capacity, adjustable speed, low energy consumption, low vibration, and low noise.

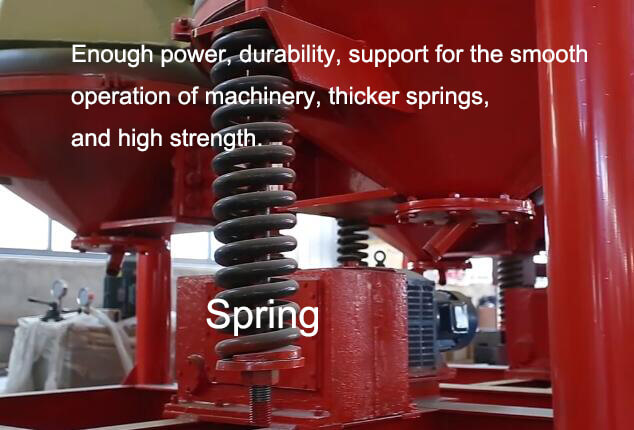

- Spring

Enough power, durability, thicker springs, and high strength.

Stationary & Mobile Jig Concentrators

Stationary Mineral Jig Separator

Mobile/Portable Mineral Jig Separator

Key Features of Stationary & Mobile Jig Concentrator

| Items | Stationary Type | Mobile Type |

| Mobility | Fixed Installation: Stationary jigs are permanently installed in mineral processing plants. They are not designed for mobility and are typically situated within a processing circuit where materials are continuously fed for separation. | Portability & Mobility: Portability is a crucial aspect of these separators. These jig machines are often mounted on trailers, skids, or other mobile platforms, allowing them to be towed or transported to remote mining sites, allowing for on-site mineral processing without the need for extensive infrastructure. |

| Environmental Considerations | Due to their fixed installation, stationary jigs might have a more significant environmental impact on site preparation, infrastructure, and energy consumption than portable units. | Because they are designed for temporary installations, portable jig separators typically have a lower environmental impact than larger-scale stationary mineral processing equipment. |

| Mining Scale | Large-Scale Mining: These separators are often used in larger mining and mineral processing operations due to their capacity and efficiency. They can handle significant throughputs and volumes of material. | Small-Scale Mining: These separators are commonly used in small-scale mining operations and exploration projects, where larger processing equipment might not be practical or economical. |

| Customization & Versatility | Either Stationary jigs or mobile jig separators, they can be designed and configured to meet the specific requirements of the processing plant and suit various mining scenarios. Different sizes and configurations can accommodate various feed rates, particle sizes, and mineral types. | |

| Applications | Mineral jig separators are used in various applications, including gold recovery, diamond recovery, tin mining, and tungsten concentration. They are particularly effective in scenarios with a significant specific gravity difference between the separated minerals. | |

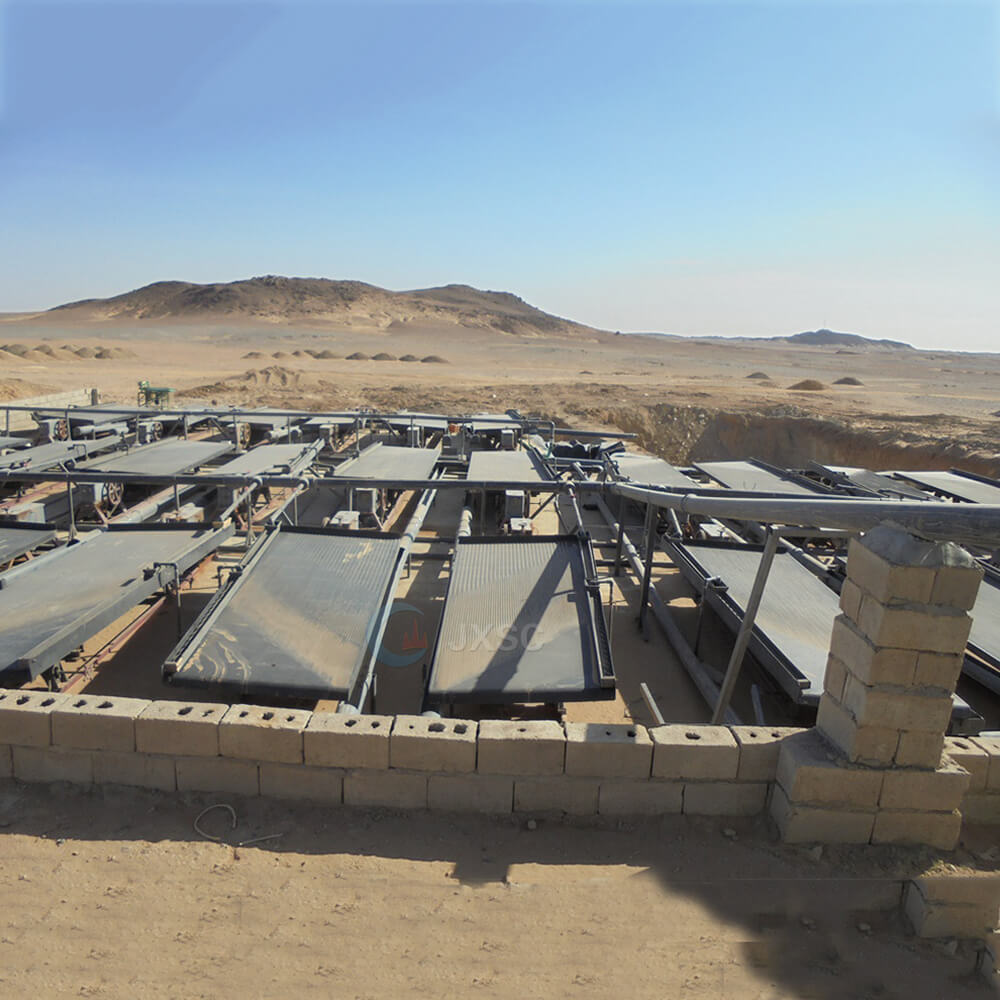

Mobile/Portable Mineral jig Separator Plant

Mobile Jig-Gold Trommel Plant

Equipment: Jig concentrator + Trommel Screen

Treatment Materials: Alluvial placer ore without sticky mud

Capacity: 1-20 TPH

A mobile jig-gold trommel plant is a combined mineral processing system incorporating a jig separator and a gold trommel into a single mobile unit. This type of plant is designed to efficiently recover gold and other valuable minerals from alluvial deposits, using a combination of gravity separation and mechanical screening.

Processing

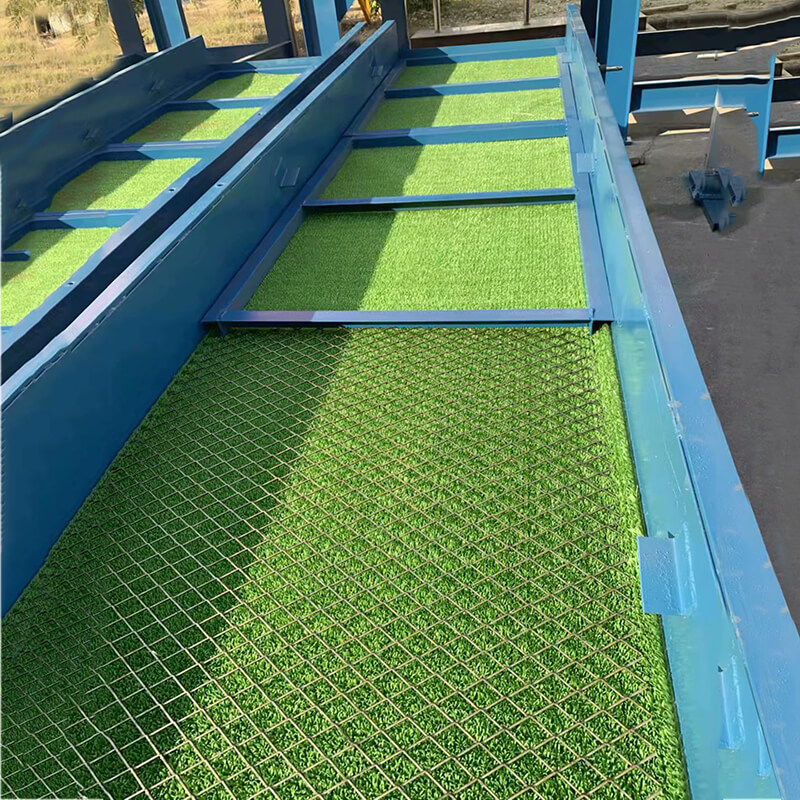

Screening & Washing: The process begins with the gold-bearing alluvial material fed into the gold trommel. A trommel is a cylindrical drum with perforated walls that rotates. As the material rotates inside the trommel, smaller particles fall through the holes, while larger rocks and debris are conveyed out the other end.

Gravity Separation: The smaller material passed through the trommel is then fed into the mobile jig separator. The jig separator uses pulsating water flow to create stratification based on the specific gravity differences of the minerals. Heavier gold particles sink to the bottom of the jig’s bed and are collected as a concentrate, while lighter gangue material is carried away as tailings.

Mobile Jig-Trommel Scrubber Plant

Equipment: Jig concentrator + Trommel Scrubber

Treatment Materials: Alluvial placer ore with sticky mud

Capacity: 1-20 TPH

A mobile jig-trommel scrubber plant is a comprehensive mineral processing system that combines the functionalities of a jig separator, a trommel scrubber, and other components into a single mobile unit. This type of plant is specifically designed for the efficient recovery of valuable minerals, especially in alluvial deposits.

Processing

Washing: The process starts with feeding the feed material into the Trommel scrubber. The trommel scrubber is a rotating drum with paddles or scrubbers that break down and disintegrate clay, soil, and other sticky materials attached to the valuable minerals. The scrubbing action helps to liberate the valuable particles from the host material.

Gravity Separation: The jig separator uses pulsating water flow to create stratification based on the specific gravity differences of the minerals. Heavier particles, including gold, settle to the bottom of the jig’s bed and are collected as a concentrate, while lighter gangue material is carried away as tailings.

Further Concentrate Collection

After the above mobile jig plants, there is a further concentrate collection if you want to improve the recovery rate. The collected concentrate from the jig separator can be further processed to recover valuable minerals, such as gold and diamond. Depending on the specific processing setup, this may involve additional steps like gold panning, sluicing, shaking tables, or using other specialized equipment for final gold recovery.

Mobile Jig Concentrator Parameters

| Model | Jig area (M2) | Feeding size (mm) | Capacity (T/H) | Stroke (R/Min) | Hutch water (T/H) | Pressure(kg/cm2) | Power (KW) | Weight (T) |

| JT0.57-1 | 0.57 | <6 | 1-2.5 | 60-160 | 1-2 | >0.3 | 1.5 | 0.612 |

| JT1-1 | 1.04 | <10 | 4-10 | 60-160 | 2-3 | 0.3mpa | 2.2 | 0.9 |

| JT2-2 | 2.28 | <10 | 8-15 | 60-160 | 2-4 | 0.3 | 3 | 1.63 |

| JT4-2 | 4 | <10 | 8-16 | 50-125 | 3-6 | 0.1 | 7.5 | 4.6 |

| JT4-2A | 4 | <10 | 8-16 | 50-125 | 4-8 | 0.1 | 5.5*2 | 4.6 |

| JT5-2 | 4.86 | <10 | 10-20 | 80-120 | 4-10 | 0.1 | 7.5 | 4.8 |