Uganda 100TPH Coltan Processing Plant

JXSC has provided a 100TPH coltan processing plant in Uganda. We design the coltan mining plant process flowchart & plant layout drawing according to ore conditions, provide a complete set of plant machines and send Chinese engineers to the mine site for plant installation & commissioning guidance.

100TPH Coltan Processing Plant Project Case

Introduction

Minerals: Coltan ore

Capacity: 100TPH

Feeding Size: ≤30mm

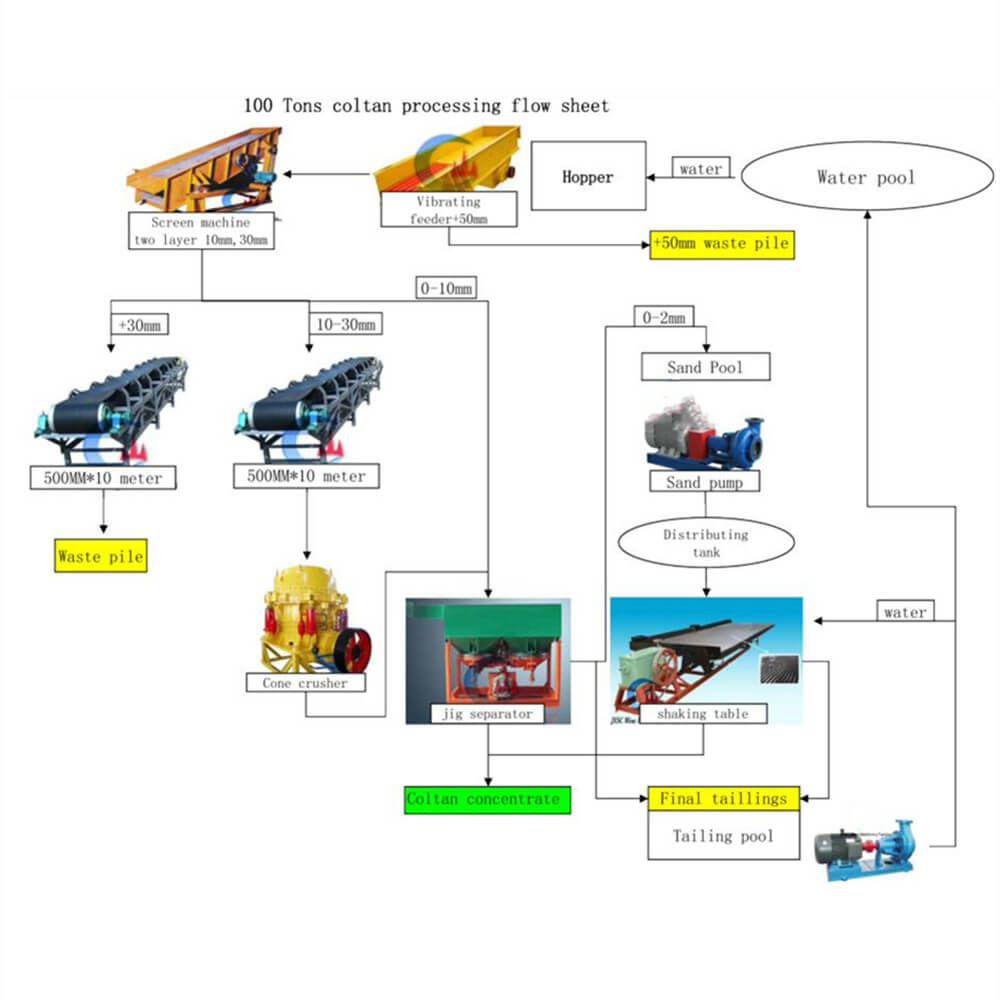

Coltan Mining Process: This Coltan mining plant adopts the sieving process to grade the raw ore, then big size fraction goes to the grinding process, then gravity separation process with jigging machines, the small concentrate would be refined by shaking table in the last step.

Solutions & Process

Coltan Process Plant

The Vibration feeder can feed coltan bearing ore evenly to the vibrating machine, the vibrating screen is used to classify the material into 3 fractions. +30mm, 10-30mm, -10 mm. 10-30mm would go to cone crush for grinding until -10mm. Jig separator is to concentrate coltan particle. +2mm coltan concentrate would generate on the sieve.

-2mm coltan concentrate would pass the jig separator screen and then re-concentrated by shaking table.