Placer Gold Mining

Placer gold mining mainly refers to mined from the land surface or river or underground. It mainly uses gravity separation because its density is much bigger than other minerals.

Introduction

About Placer Gold

Placer gold refers to the gold formed by the rock gold in the mountain washed by the river and separated from the quartz vein. Because this kind of gold is as fine as sand, it is called placer gold.

Gold mining is divided into rock cave digging and panning in rivers and streams containing gold. For example, gold taken from mines is called gold or melon seed gold, and gold panned from gravel in water is collectively referred to as placer gold Generally speaking, the gold ore is larger, and most of the placer gold is as fine as sand, which is called placer gold.

Types of Placer Deposit

According to the landform and formation conditions, placer gold can be divided into

- River gold deposit, in the river bed, bank, or shoal.

- Flood plain gold deposits, mostly large and medium-sized deposits.

- Terrace gold deposits, in the valley slope terrace area, most of them are the remaining parts of the original floodplain gold deposits that were eroded.

- Valley gold deposits are usually in coarse size, with high grade and low water content, it is a good source of gold production, but a shortage on small scale.

- Karst gold deposits are often produced in karst tunnels and caves.

Mineral Processing

Placer/Alluvial Gold Mineral Processing

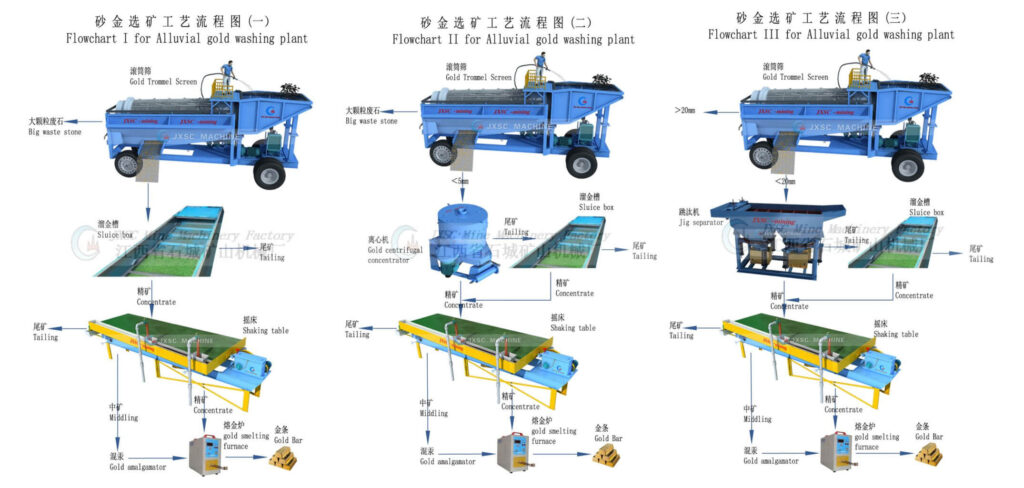

Gold Washing: This process is for wash clean the clay and mud in raw material, most popular used are the gold trommel scrubber washer and gold washing trommel screen. A gold trommel scrubber is for washing raw material with much sticky clay, trommel screen is for washing raw material with no sticky clay.

Sieving: After washing, need to sieve out some bigger waste material, the under-screen slurry will go to the next machine. This process can use a trommel screen or vibration screen or high-frequency vibration screen.

Primary Concentration: This process is for rough gold concentration, and can use a gold centrifugal concentrator or gold jig separator. The concentrated ore from them will go to the final concentration machine.

Final Concentration: The concentrated ore from the jig machine or centrifugal will go to the gold shaking table for the gold final concentration, which can get high purity gold.

Tailing Recovery: Usually will use a gold sluice box to recover tailings that come from a centrifugal machine. So can get more gold.

Refining: If some customer needs very very high purity gold and need to smelt it on the gold bar for sale, they can use a gold smelting furnace to smelt gold dust on a gold bar.