Ilmenite Mining Process

The Ilmenite beneficiation process depends on the nature of ilmenite. Common beneficiation methods for ilmenite include gravity separation, flotation, magnetic separation, electric separation, and their combined processes.

Introduction

About Ilmenite & Titanium

Ilmenite is a common accessory mineral in igneous rocks, sediments, and sedimentary rocks in many parts of the world. It is an oxide mineral of iron and titanium, also known as titanium magnetite, and its composition is FeTiO3. Ilmenite is a heavy (specific gravity 4.7), moderately hard (Mohs hardness 5.6 to 6), opaque black mineral with a submetallic luster. The crystals are generally plate-shaped, and the crystals are aggregated together as massive or granular.

The content of ilmenite TiO2 is 52.66%, which is the main mineral for extracting titanium and titanium dioxide. Titanium is a metal needed to make a variety of high-performance alloys. Titanium dioxide(TiO2) is an important pigment, whiting, and polishing abrasive.

Titanium is a chemical element with the symbol Ti and atomic number 22. Found in nature only as an oxide, and it can be reduced to produce a lustrous transition metal with a silver color, low density, and high strength, resistant to corrosion in seawater, aqua regia, and chlorine.

Titanium can be alloyed with iron, aluminum, vanadium, and molybdenum, among other elements, to produce strong, lightweight alloys for aerospace (jet engines, missiles, and spacecraft), military, industrial processes (chemicals and petrochemicals, desalination plants, pulp, and paper), automotive, agriculture (farming), medical prostheses, orthopedic implants, dental and endodontic instruments and files, dental implants, sporting goods, jewelry, mobile phones, and other applications.

Mineral Processing

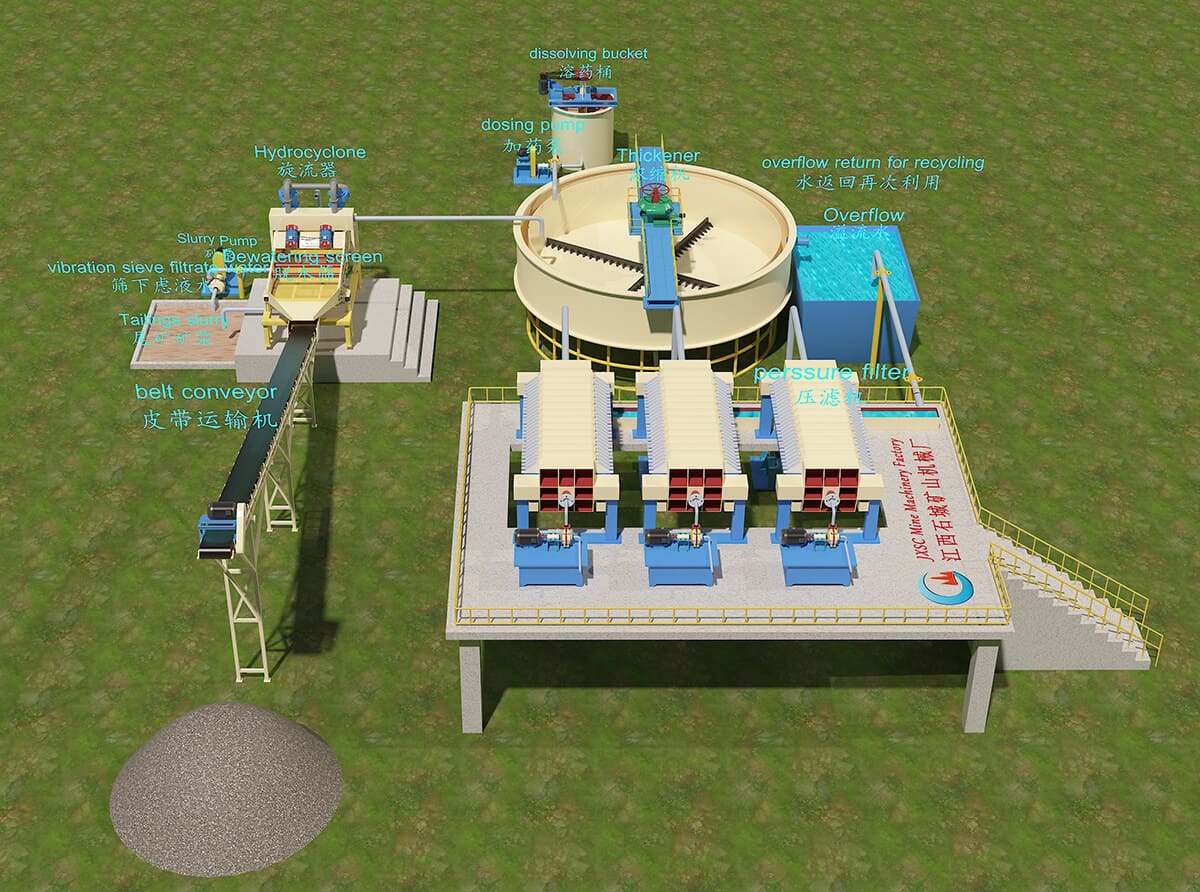

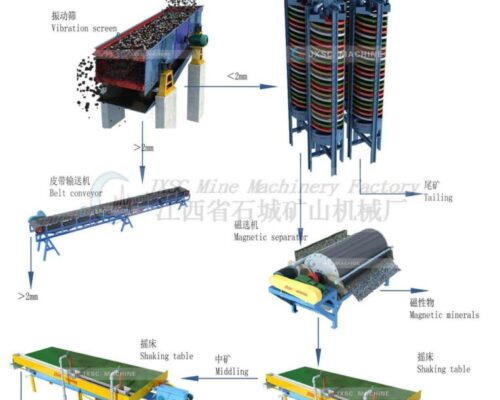

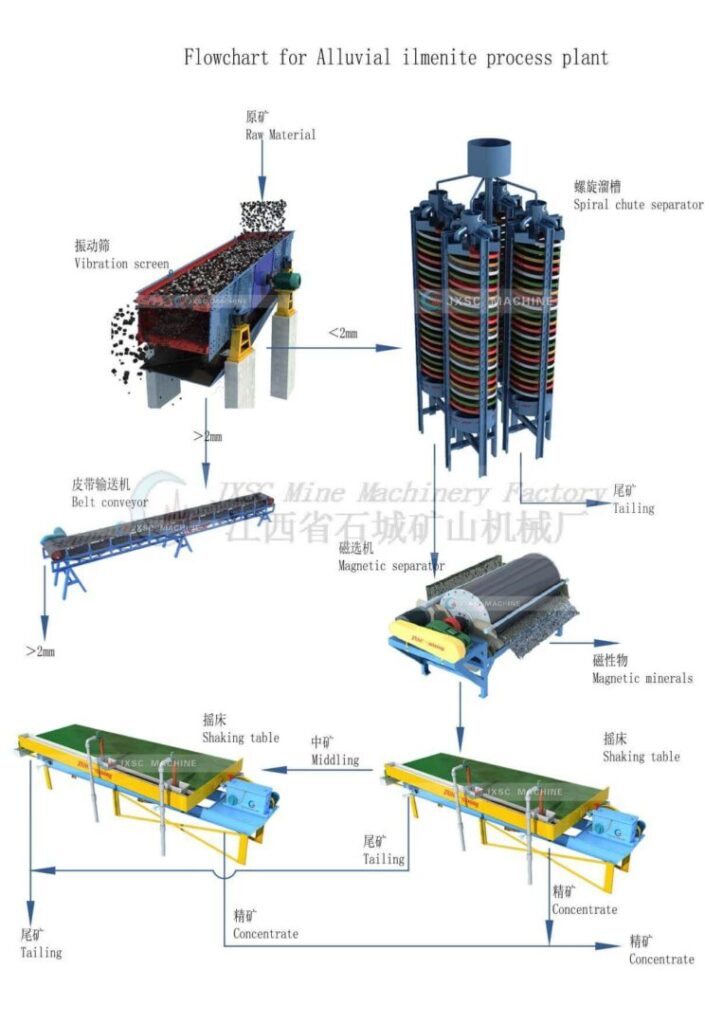

Alluvial Ilmenite Process Plant

Rock Titanium Process Plant

Ilmenite Beneficiation Process

Ilmenite gravity separation

The gravity separation method is suitable for processing coarse-grained and fine-grained aggregate disseminated ilmenite. After crushing, the raw ilmenite ore is separated and discarded by gravity separation equipment, such as the shaking table, spiral chute, etc. A large number of gangue minerals and slime are discarded. The gravity separation method has low investment, a good separation index, and little environmental pollution, so it is widely used in small-scale mines.

Ilmenite Flotation

The flotation method is suitable for the separation process of fine-grained ilmenite and the beneficiation of primary titanium-containing ore. It has the advantages of high separation accuracy and good separation effect. The flotation process includes conventional flotation, agglomeration flotation, flocculation flotation, etc.

Ilmenite Magnetic Separation

Ilmenite is a weak magnetic mineral. Under the same volume, the volume magnetization of ilmenite is much larger than that of gangue minerals. Strong magnetic separation can realize the effective separation of ilmenite and gangue minerals and achieve the purpose of enrichment. Ilmenite magnetic separation is often used in the concentration process, and it is better for separating coarse-grained and fine-grained ilmenite.

Ilmenite Electric Separation

The electric separation method is mainly used to process the rough concentrate after gravity separation and magnetic separation containing non-conductive impurities and is mainly used for concentration operations. Pretreatments such as radiation irradiation and heating are required before electro-selection to ensure the regular progress of the electro-selection process, avoid unnecessary situations, and improve the efficiency of ore dressing.

Combined Ilmenite Process

The beneficiation process of ore is determined by its nature. When the ilmenite composition is complex, using a beneficiation method to achieve a good separation effect is difficult. Therefore, it is necessary to use a combined process. The common ilmenite combined technological process includes magnetic separation-flotation, magnetic separation-gravity separation, gravity separation-flotation, gravity separation-magnetic separation-flotation-electric separation, etc.