Raymond Grinding Mill

Capacity: 1-25 T/H

Feeding Size: <40mm

Discharge Size: 0.045-0.6mm

Process Material: The material below scale 6 of Mohs hardness and 250-odd sorts of non-inflammable and non-explosive stuff for high fine powder generation and processing, such as talcum, barite, marble, limestone, charcoal blacks.

Raymond Grinding Mill Overview

The Raymond grinding mill Machine is mainly suitable for the processing of materials in the building materials, chemical industry, metallurgy, mining, abrasives, refractory materials, ceramics, iron and steel, electric power, coal, and other industries. It can grind quartz stone, barite, fluorite, rare earth, marble, ceramics, iron ore, copper ore, phosphate rock, slag, water slag, cement clinker, activated carbon, dolomite, granite, coking coal, lignite, diamond Beautiful sand, chrome oxide green, gold ore, red mud, clay, kaolin, coke, coal gangue, china clay, fluorspar, bentonite, diabase, pyrophyllite, phyllite, basalt, gypsum, graphite, silicon carbide, thermal insulation materials Various non-flammable and non-explosive mineral materials with Mohs hardness below 9 and humidity below 6%.

Advantages

Raymond Grinding Mill Advantages

- Long service life: Resilient coupling between the main engine and separator can reduce the vibration and noise and improve the service life of the equipment.

- Simple system and compact layout

- Can be an outdoor arrangement and reduce the investment cost a lot

- Seal with excellent seal performance

- Environmental protection: Unique air circulation system with Advanced dust remover carries

- Efficient and energy-saving

- Convenient impeller adjusting devices improve the precision of the finished product.

Structures & Working Principle

Raymond Grinding Mill Structure

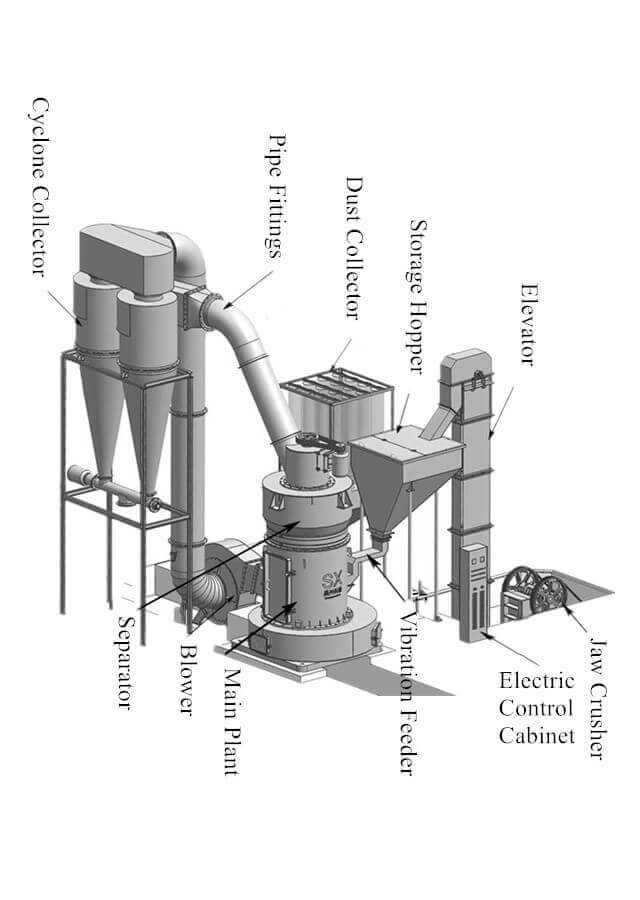

The main parts of a raymond grinding mill plant are a cyclone collector, pipe fittings, dust collector, storage hopper, elevator, crusher, electric control cabinet, feeder, main plant, blower, separator, etc.,

Raymond Grinding Mill Working Principle

After the bulk material is crushed to the required particle size by the jaw crusher, the material is sent to the storage hopper by elevator, and then the material is continuously fed in evenly and quantitatively through the vibrating feeder Grinding in the main machine grinding chamber, the ground powder is taken away by the airflow of the fan, and classified by the analyzer. The fineness of the powder enters the large cyclone collector through the pipe with the airflow for separation and collection, and then the powder is discharged The valve discharge is the finished powder. The airflow is sucked into the blower by the return duct at the upper end of the large cyclone collector. The entire airflow system of this machine is closed and circulating, and it circulates under the condition of positive and negative pressure.

Technical Parameters

| Model | Roller | Ring | Feeding Size (mm) | Finished Size (mm) | Motor Powder (kw) | Capacity (t/h) | Overall Dimension (mm) | |||

| Quantity (piece) | Diameter (mm) | Height (mm) | Inner Diameter (mm) | Height (mm) | ||||||

| YGM7815 | 3 | 260 | 150 | 780 | 150 | 15 | 0.613-0.033 | 18.5 | 1–3 | 4300*3500*5100 |

| YGM8314 | 3 | 270 | 140 | 830 | 140 | 20 | 0.613-0.033 | 22 | 1.2–4.6 | 5300*4100*5200 |

| YGM9517 | 4 | 310 | 170 | 950 | 170 | 25 | 0.613-0.033 | 37 | 2.1-5.6 | 7100*5900*7900 |

| YGM4121 | 5 | 410 | 210 | 1280 | 210 | 30 | 0.613-0.033 | 75 | 2.8-10.5 | 9200*7250*9700 |

| MTM160 | 6 | 440 | 270 | 160 | 270 | 35 | 0.613-0.033 | 132 | 5–20 | 12550*5700*8350 |