Mobile & Standard

Modular Mineral Processing Plant

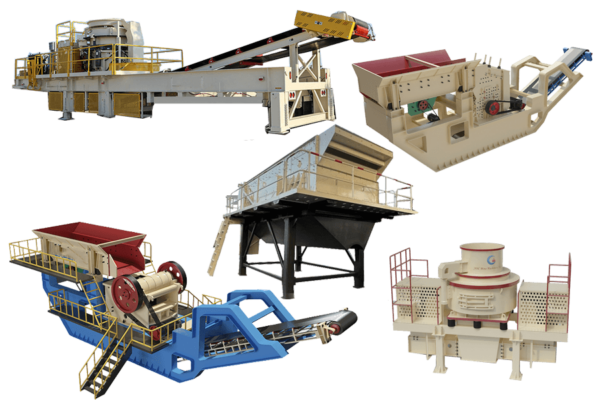

Modular Mineral Processing Plant Solutions

A modular plant is an affordable mineral processing solution that does not compromise metallurgical performance. We utilize a team of expert engineering professionals to design modular and fixed mineral processing plants. We utilize various testing methods, ranging from unit process operations to complete mineral and metal recovery solutions. We specialize in the production of complete processing equipment.

Applications

- Conveying systems

- Crushing and screening systems

- Gravity recovery systems

- Construction aggregate washing and classfication

- Mineral recovery

Features

- Shorter delivery times to production, improved speed to market

- Easy to move and transport around the world

- Easy site construction & commissioning

- Fully customizable

- Lower material cost, affordable models

- Flexible, expandable, relocatable & optional add-ons.

Standard Modular Mineral Processing Plant

Our modular plant combines simple modular design with large-scale engineering. It offers a highly efficient yet compact layout, utilizing advanced process design methodology. With a capacity from 5tph up to 1200tph, each module can be customized with a circuit to suit even the most challenging ore body.

Modular Crushing & Screening System

Customized crushing plant

Sand Washing & Recycling Machine

Capacity: 15-260 TPH

Configured Equipment

River Stone & Sand Processing Plant

500TPH Stone Crushing Plant

150TPH Limestone Jaw Crusher Plant

Sand Making and Washing Plant

Our

Modular Plant

Advantages

- Cost and Risk Reduction

- Fast Commissioning and Startup

- Quality Construction & Reliability

- Global Solutions

- Proven Standard Design

Mobile Mineral Processing Plants

A mobile modular mineral processing plant is also called a mobile mining plant, a set of flexible and efficient small and medium-sized portable concentrator systems. Because of the characteristics of some mines with high-grade gold ore, coarse embedded particle size, and small and scattered mining scale. This system adopts the design concept of modularization and integration and is mainly used for recovering gold minerals in mines with small-scale and scattered sources of raw materials.

Mobile Crushing & Screening Plants

Mobile Crusher Station Types:

Mobile Diamond & Gold Washing Plant With Jig

Applicable Materials:Alluvial Diamond/Gold

Capacity: 0-20 TPH

Modular Configuration

Capacity: 0-250 TPH

Feeding Size: <230mm

Equipment:

- Trommel Scrubber

- Sluice Box

Capacity: 0-300 TPH

Equipment:

- Gold Washing Trommel

- Sluice Box

Capacity: 0-60 TPD

Equipment:

Gold Centrifugal Concentrator

Shaker Table

Capacity: 2-3 TPD

Equipment:

- Gasoline Engine

- Water Pump

- Sluice Box