Heavy Hammer Crusher

Capacity: 50-1200 TPH

Feeding Size: ≤1200 mm

Power: 75-500 kW

Application: Suitable for crushing various medium-hard and brittle materials.

Heavy Hammer Crusher Overview

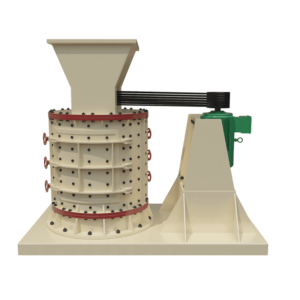

Heavy hammer crusher is also called hammer crusher. It has the characteristics of one-time shaping, a large crushing ratio, high production capacity, and uniform product size. It is suitable for fine-crushing limestone, coal, or other medium hardness in industrial sectors such as metallurgy, building materials, chemical industry, and hydropower. The brittle materials have advanced product structure, reliable performance, and low energy consumption.

The heavy hammer crusher is commonly used for crushing materials with compressive strength not exceeding 200MPa, such as limestone, gypsum, coal, marl, sandstone, and shale. It is widely used in highways, railways, airport runways, mines, coal mines, construction, garbage and construction waste recycling, hydropower projects, urban infrastructure, roads or construction sites, etc., requires relocation, and is highly mobile operations.

Features

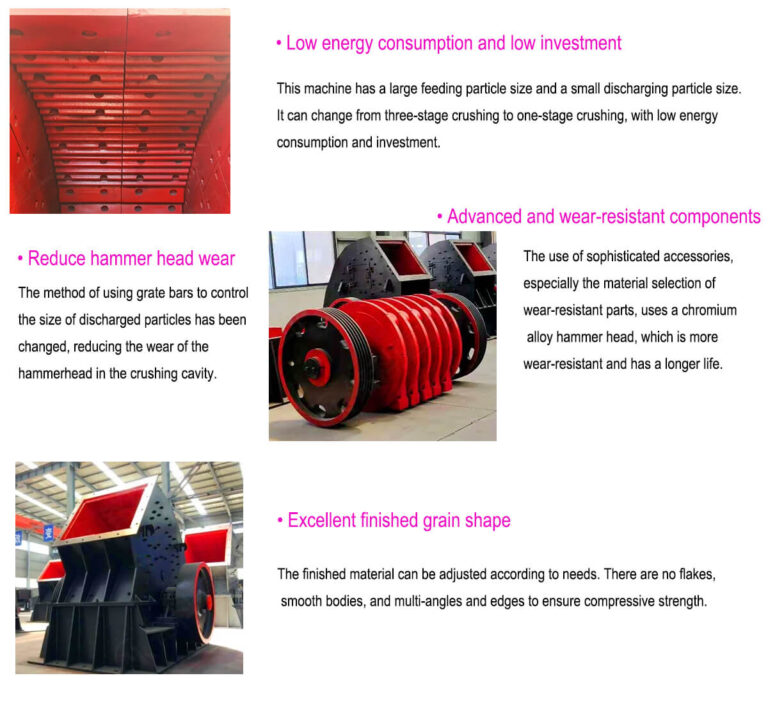

- Low energy consumption and low investment

This machine has a large feeding particle size and a small discharging particle size. It can change from three-stage crushing to one-stage crushing, with low energy consumption and investment. - Reduce hammer head wear

The method of using grate bars to control the size of discharged particles has been changed, reducing the wear of the hammerhead in the crushing cavity. - Advanced and wear-resistant components

The use of sophisticated accessories, especially the material selection of wear-resistant parts, uses a chromium alloy hammer head, which is more wear-resistant and has a longer life. - Excellent finished grain shape

The finished material can be adjusted according to needs. There are no flakes, smooth bodies, and multi-angles and edges to ensure compressive strength.

Advantages

Heavy Hammer Crusher Advantages

- Large feed particle size and high output

The feed particle size of the hammer crusher can reach 1200 mm, and the output of a single hammer crusher can reach 1200 tons.

The design of the crushing chamber conforms to the dynamic principle. The unique sieve plate-less structure increases the material throughput, can crush wet materials, and solves the problems of straightforward blockage and low output of traditional hammers. - Low energy consumption and low investment

The heavy hammer crusher has a large feed particle size and a small discharge particle size. The one-time molding system ultimately realizes low-cost operation. - Environmentally friendly and less polluting

It can crush wet materials. Add water when crushing wet materials to reduce dust pollution and protect workers’ health and the environment. - Excellent finished product particle size

The material can be adjusted according to needs to meet various specifications.

Structures & Working Principle

Heavy Hammer Crusher Structure

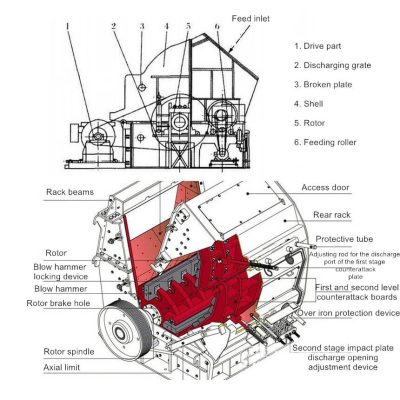

The rotor of the hammer crusher consists of a main shaft, a disc, a pin, and a hammer.

Heavy Hammer Crusher Working Principle

The motor drives the rotor to rotate in the crushing chamber at high speed. The material is fed into the machine from the upper feeding port and crushed by the high-speed hammer’s impact and grinding action. In the lower part of the rotor, there is a sieve plate. The particles smaller than the screen hole size in the crushed materials are discharged through the sieve plate. The coarse particles larger than the screen hole size are retained on the sieve plate continue to be hit and ground by the hammer, and finally pass through the sieve plate. discharged from the machine.

Technical Parameters

| Model | Rotor Dia (mm) | Inlet Size W*L (mm) | Feeding Size (mm) | Capacity (t/h) | Power (kW) | Dimension (mm) |

| ZPC0706 | 700*570 | 615*510 | <400 | 50-70 | 75 | 1950*1340*1480 |

| ZPC0808 | 800*750 | 780*610 | <500 | 80-100 | 132 | 2280*1790*1670 |

| ZPC0910 | 9000*1000 | 1070*750 | <600 | 150-200 | 110*2 | 2600*2200*1940 |

| ZPC1012 | 1000*1180 | 1255*810 | <650 | 250-300 | 132*2 | 2800*2310*2210 |

| ZPC1213 | 1200*1280 | 1350*920 | <750 | 300-350 | 160*2 | 2970*2580*2510 |

| ZPC1216 | 1200*1590 | 1530*920 | <750 | 400-500 | 200*2 | 3070*2840*2580 |

| ZPC1220 | 1220*1950 | 2000*920 | <750 | 500-600 | 220*2 | 3080*3380*2580 |

| ZPC1310 | 1310-1050 | 890*1075 | <650 | 150-180 | 160 | 2950*2250*2490 |

| ZPC1512 | 1500*1160 | 1200*900 | <750 | 250-310 | 160*2 | 3250*2624*2750 |

| ZPC1513 | 1500*1350 | 1290*900 | <750 | 300-350 | 180*2 | 3250*2624*2750 |

| ZPC1615 | 1650*1452 | 1500*1200 | <1000 | 410-500 | 220*2 | 3660*2930*3430 |

| ZPC1620 | 1660-1900 | 2000*1200 | <1200 | 800-1000 | 400*2 | 3665*3200*3435 |

| ZPC1622 | 1620*2200 | 2200*1000 | <900 | 600-800 | 250*2 | 3690*3250*3450 |

| ZPC1815 | 1850*1520 | 1500*1280 | <1100 | 520-620 | 250*2 | 3680*2915*3510 |

| ZPC1820 | 1800*1964 | 2000*1200 | <1200 | 1000-1200 | 450*2 | 3700*3270*3515 |