Nigeria 300-400TPH Granite Crushing Plant

JXSC has provided a successful 300-400TPH granite crushing plant in Nigeria. We design the ore process plant flowchart & plant layout drawing according to ore conditions, provide a complete set of plant machines and send Chinese engineers to the mine site for plant installation & commissioning guidance.

Granite Crushing Plant Project Case

Introduction

Minerals: Granite

Capacity: 300-400 TPH

Feed Size: <750mm

Output Size: 0-6mm,6-13mm,13-19mm,19-25mm

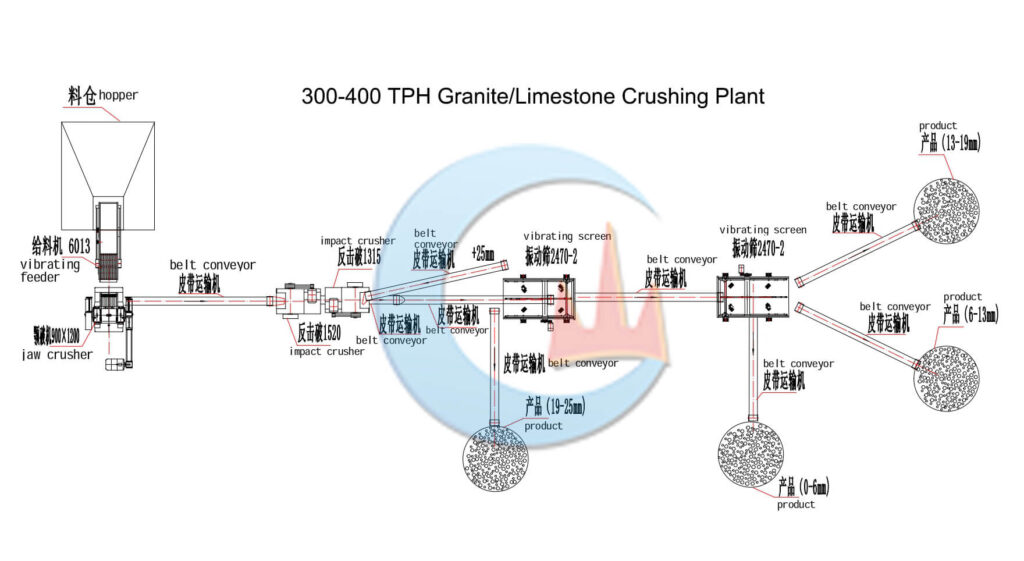

Process: Feeding ->coarse crushing -> secondary crushing -> screening

Solutions & Process

Granite/Limestone Crushing Process

Steps of the crushing plant

- Unload the raw materials to the hopper.

- Raw materials will flow evenly into vibrating feeder DN600*130, which feeds raw materials to jaw crusher PE-900*1200.

- After crushing by jaw crusher PE-900*1200, the output from the jaw crusher goes to the first impact crusher PF1520 via belt conveyor B1200*25.

- The output from impact crusher PF1520 goes to the first vibrating screen 2YD2470(screen mesh size 19mm, 25mm) via belt conveyors B1200*13& B1200*28.

- After screening by the first vibrating screen 2YD2470, the +25mm materials return to the second impact crusher PF1320 via belt conveyor B1000*21.

- The 19-25mm materials from the first vibrating screen 2YD2470 go to stockpile by the final product belt conveyor B800*20.

- The 0-19mm materials from the first vibrating screen 2YD2470 go to the second vibrating screen 2YD2470(screen mesh size 6mm, 13mm) by belt conveyor B1000*23.

- After screening by a second vibrating screen, can get 0-6mm, 6-13mm, and 13-19mm materials, will be sent to stockpiles by final product belt conveyors B800*20.

This 300-400TPH Granite crushing process is also fit for limestone crushing.