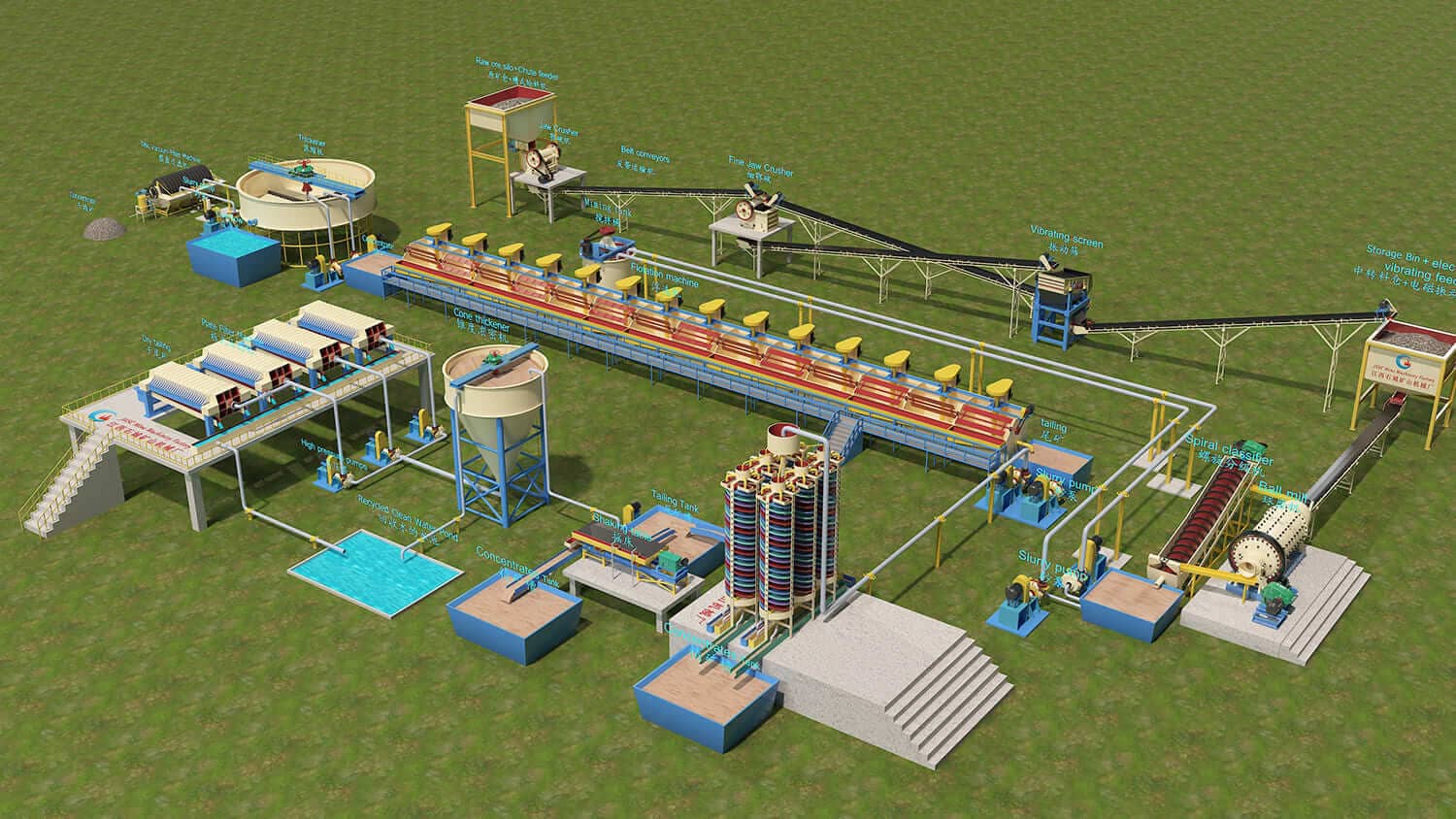

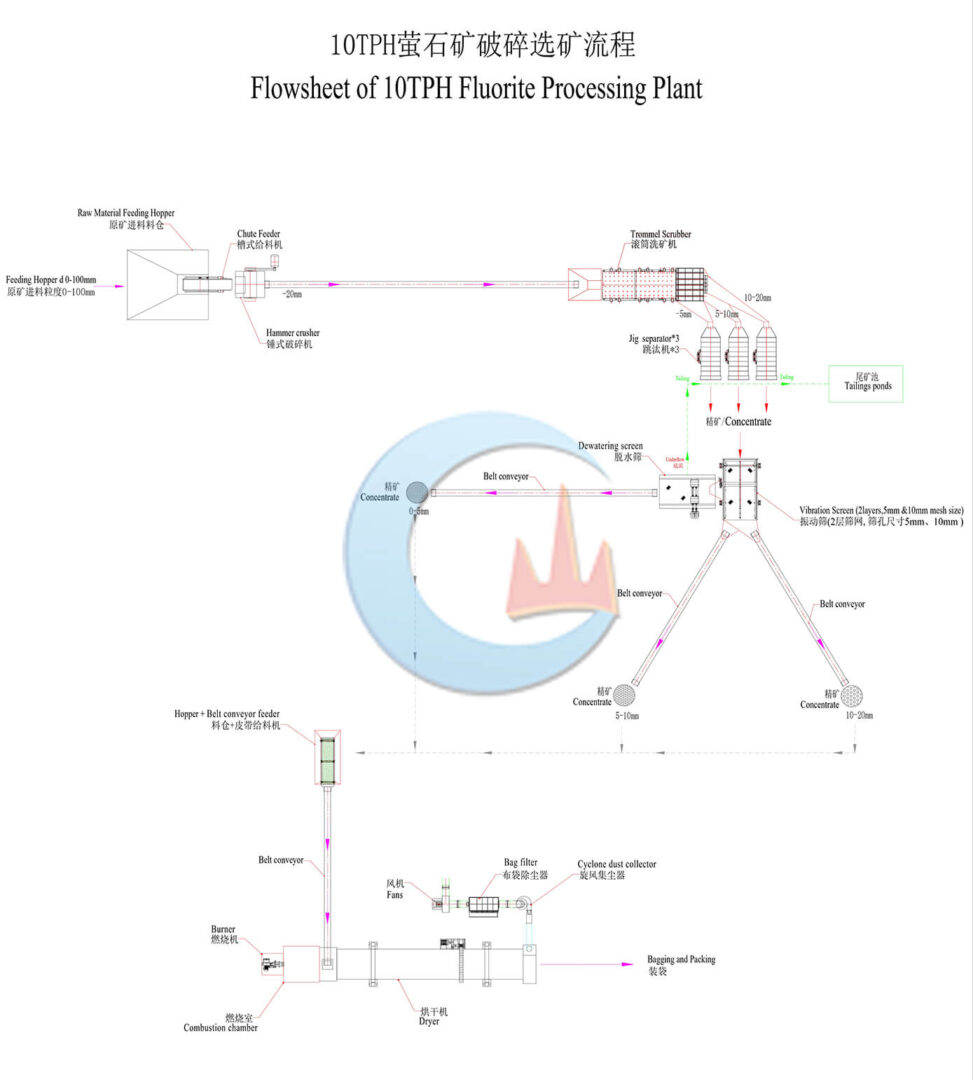

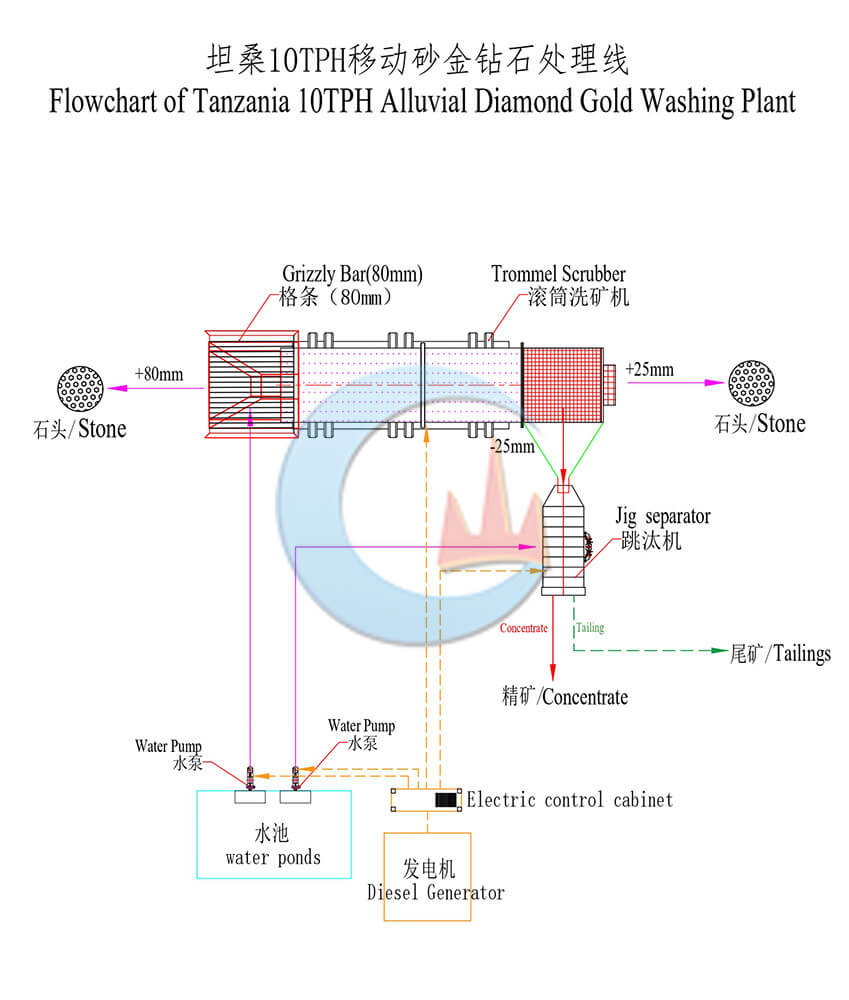

JXSC has provided a successful 10TPH alluvial diamond gold washing plant in Tanzania. We designed the ore process plant flowchart and plant layout drawing according to ore conditions. We provided a complete set of plant machines to the mine site.

EPCS

Engineering, Procurement & Construction Services

Case Study: Alluvial Diamond Gold Washing Project

Project Overview

Minerals

Allucial Diamond & Gold Ore

Capacity

10 TPH

Feed Size

<80 mm

Location

Tanzania

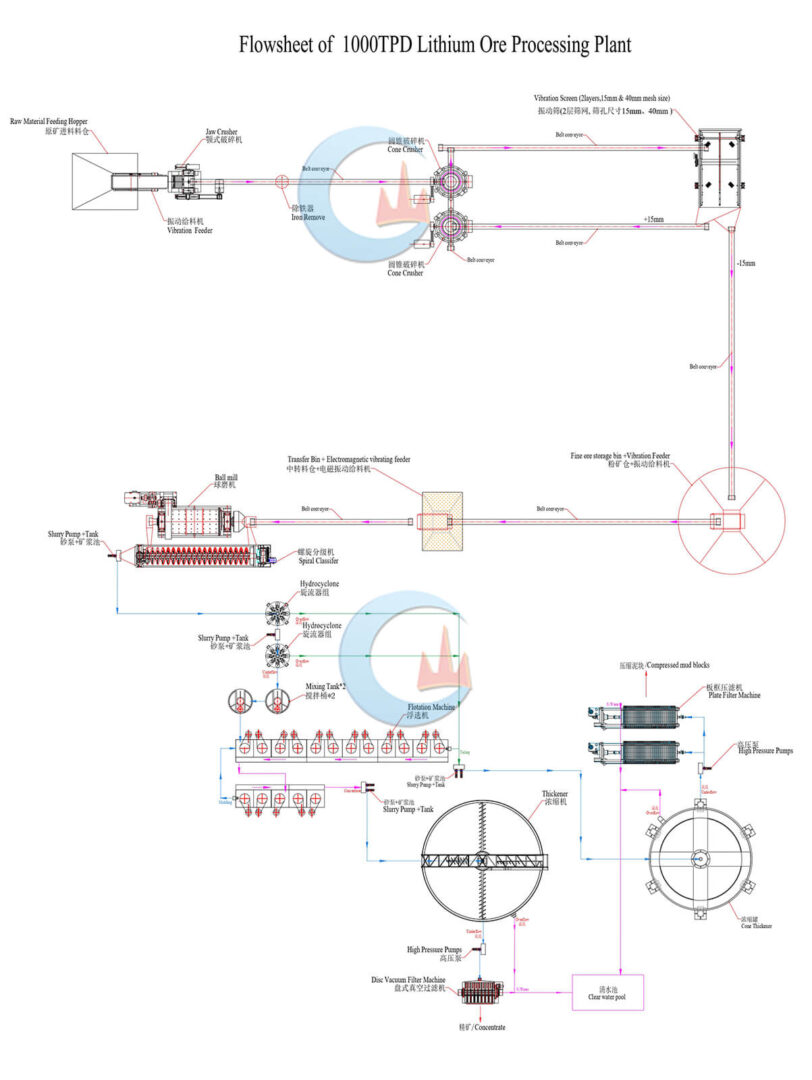

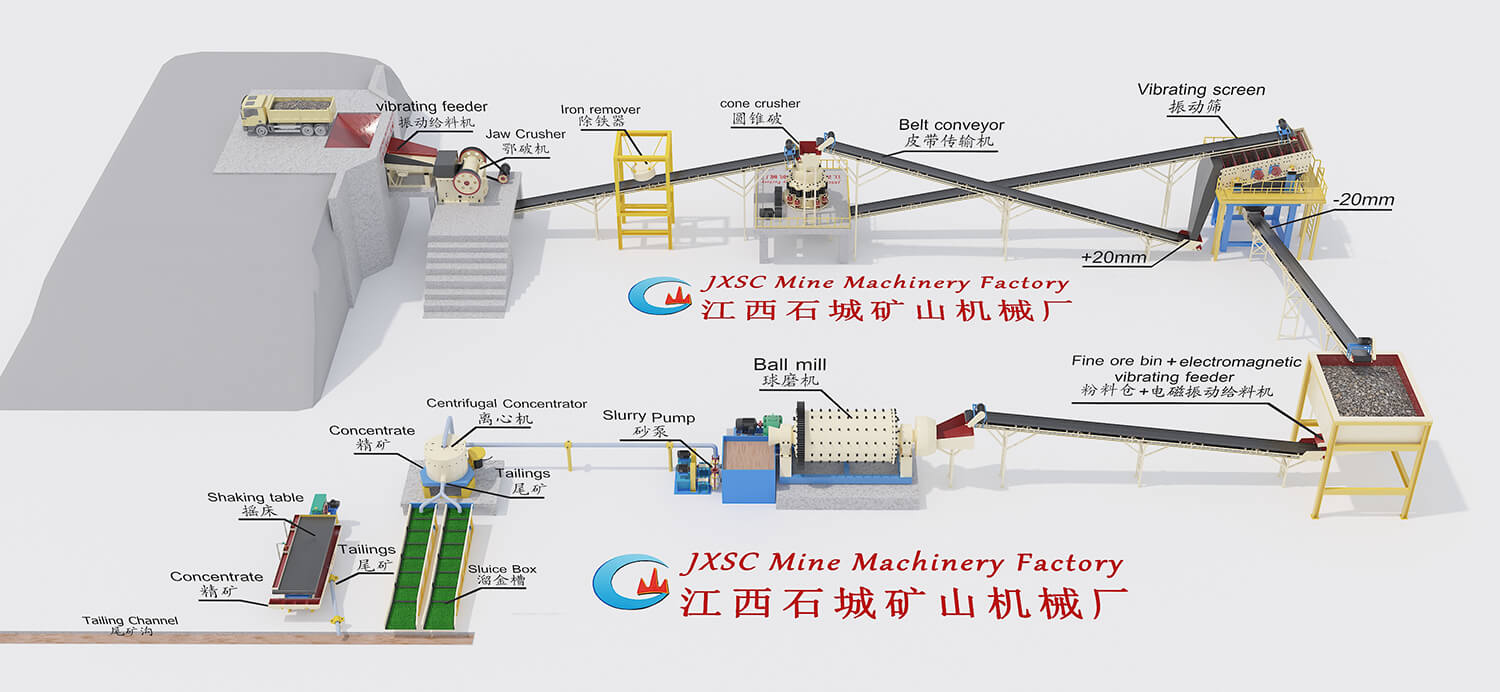

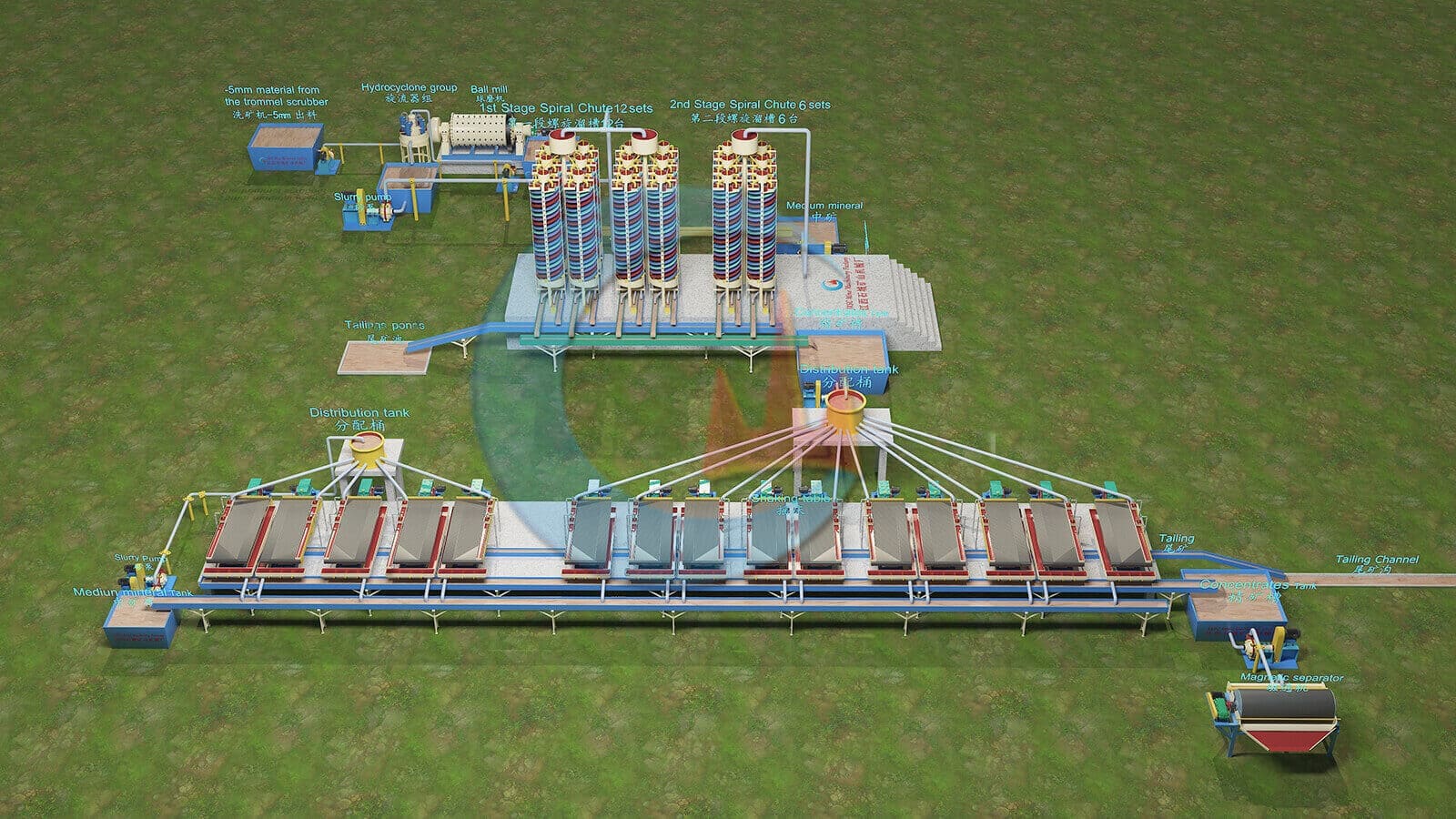

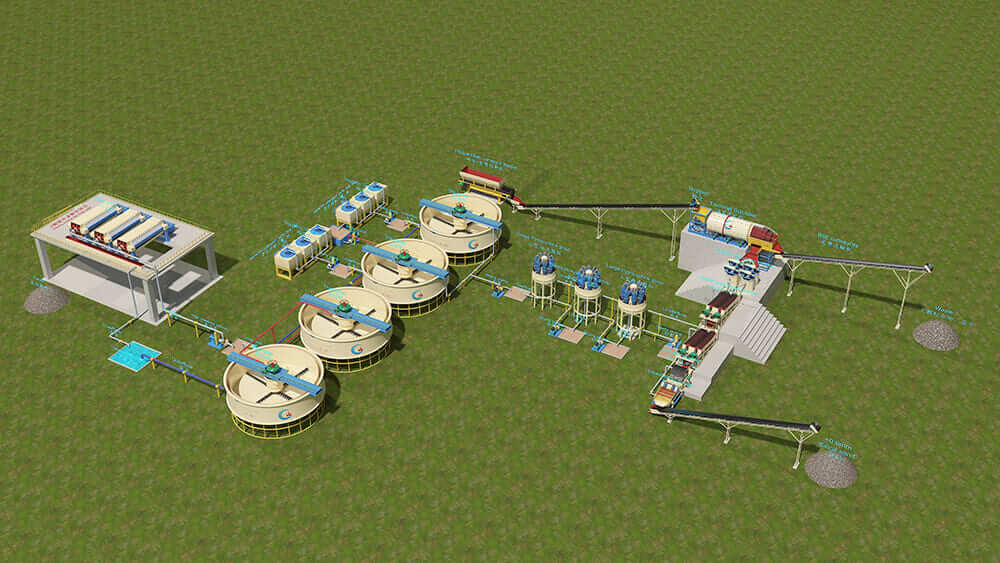

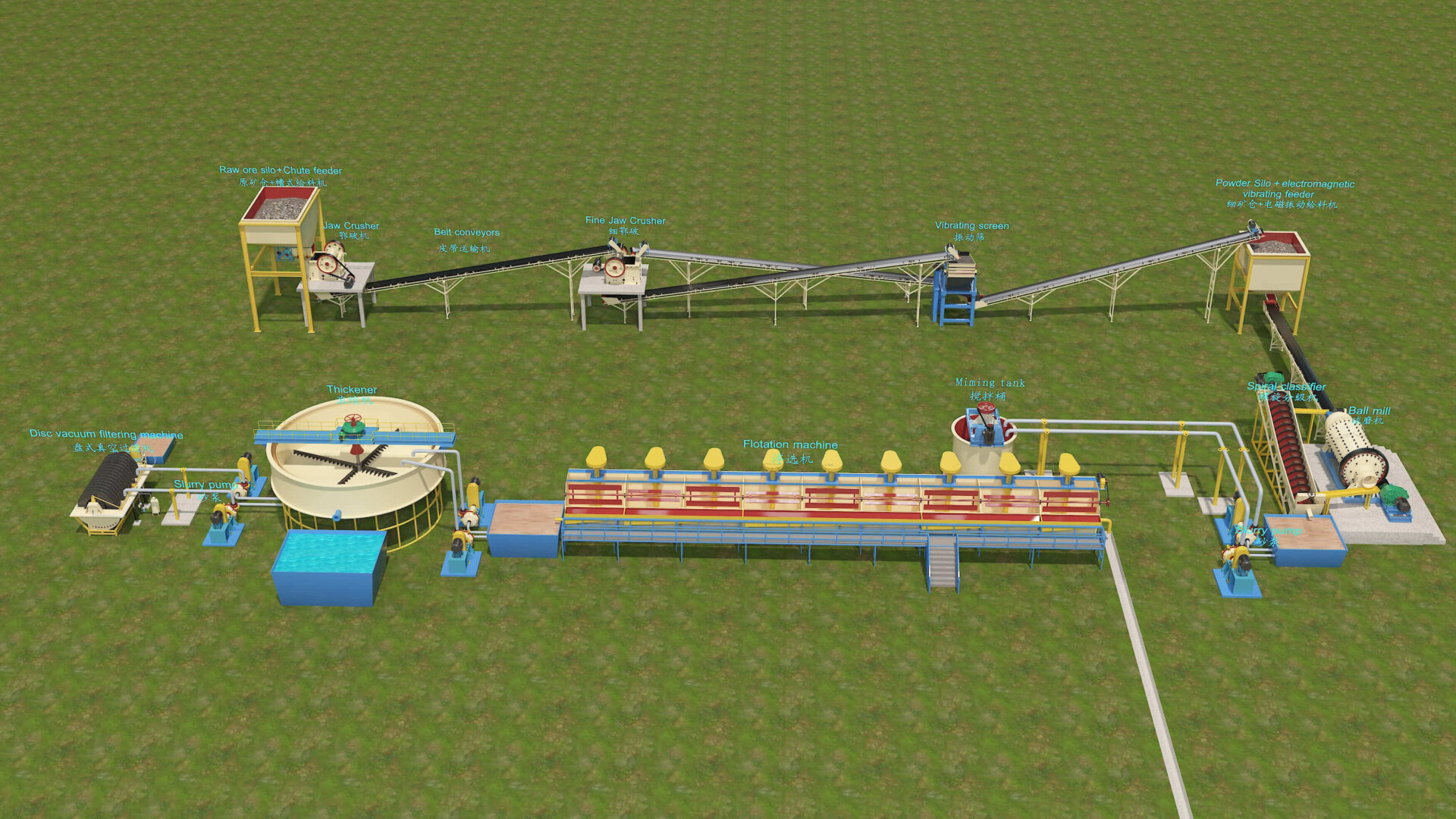

Project Process

Solutions & Process

Alluvial Diamond Gold Washing Plant Processing

This is a brief overview of the process at the Tanzania 10TPH alluvial diamond and gold washing plant, aimed at efficiently extracting gold and diamonds from sand while emphasizing environmental protection and resource management.

Raw Material Feed

The raw material (containing gold and diamonds) is fed into the beginning of the process through the feed inlet.

Grizzly Screening

- The material first enters the grizzly bar, which is used for the preliminary separation of stones larger than 80mm from smaller ore material.

- Stones larger than 80mm are discharged, while the smaller ore material progresses to the next step.

Washing Process

- The ore then flows into the trommel scrubber. In this washing machine, the ore material is mixed with water, and through rotation and water flow, dirt and impurities adhering to the surface are washed away.

- After washing, the ore is classified into different particle sizes, with smaller particles moving on to the next processing step.

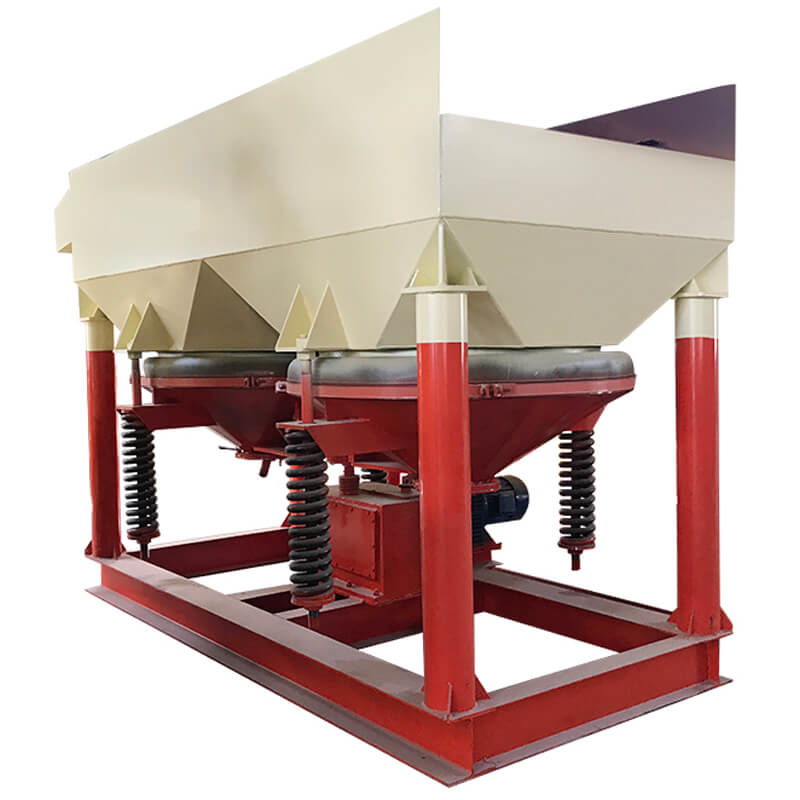

Jig Separation

- The cleaned ore is then fed into the jig separator. This device separates materials based on differences in density.

- In the jig, heavy minerals (like gold and diamonds) are separated due to their higher density, forming a concentrate, while lighter minerals and impurities constitute the tailings.

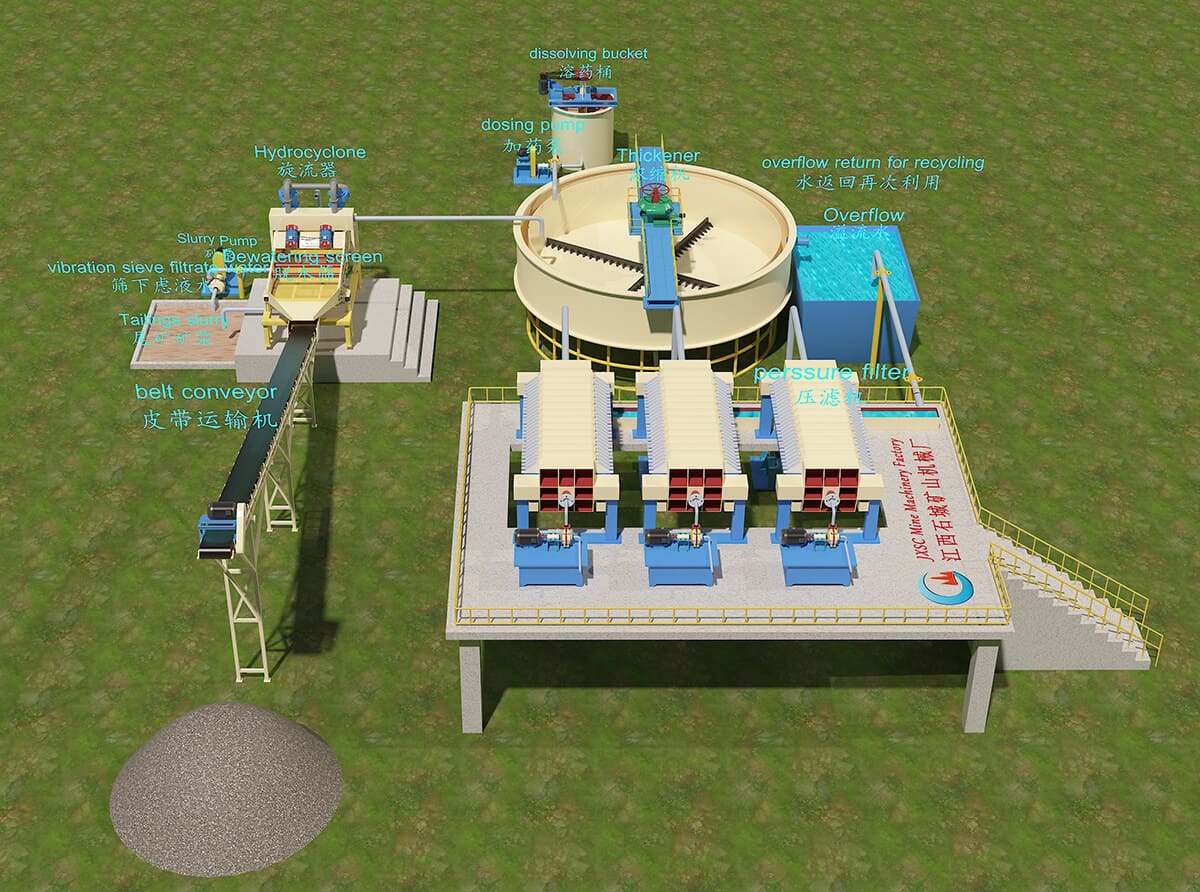

Pumping System

Throughout the entire process, the water pump is responsible for supplying the water needed by the trommel scrubber and the jig. The pump draws water from the water ponds, allowing for recirculation and ensuring efficient washing and separation activities.

Concentrate and Tailings Management

The concentrate is collected in designated containers for further treatment and purification, while the tailings are managed through effective measures to minimize environmental impact.

Power and Control

- The entire equipment system is powered by a diesel generator, ensuring the normal operation of all processing units.

- The electric control cabinet is used to manage the electrical distribution and operational status of the equipment, ensuring the efficiency and safety of the entire process.

Equipment In This Project

Related Cases

We are a leading provider of innovative and efficient mining equipment and solutions. With years of experience in the industry, we specialize in designing and manufacturing high-quality machines tailored for various mineral processing needs, including gold, diamond, copper, tin, manganese, chrome, titanium, and other ore separations. Our commitment to technology and customer satisfaction drives us to deliver customized solutions that enhance productivity and ensure environmentally sustainable practices. Explore our extensive portfolio of successful case studies and discover how JXSC can transform your mining operations, helping you maximize your profitability while minimizing your ecological footprint. Choose Us—where technology meets efficiency in the world of mining!