Blogs Related Mining Equipment, Projects & Process Plants

What Is & How to Optimize the Circulating Load in a Closed-circuit Grinding System?

Grinding systems are the backbone of mineral processing plants. But inefficient grinding can drain energy and reduce productivity. One key parameter for optimization is “circulating load.” Circulating load refers to the amount of coarse material returned to the grinding mill for reprocessing in a closed-circuit system. Optimizing this load improves

Ore Washing Technology and Equipment in Mineral Processing

In mineral processing, ore rich in clay or fine silt often leads to issues such as increased flotation reagent consumption and reduced magnetic separation efficiency. As a result, ore washing has become a key step in pre-treatment, effectively removing surface attachments through crushing and separation to improve subsequent mineral processing

Unlocking Gold: A Guide to Ore Types and Their Processing Methods

Gold, as a globally strategic resource, has seen its price soar in recent years, making the efficient recovery of gold ore a top priority in the mining industry. Given the diverse types of gold ores—each with unique mineral compositions and gold occurrence states—tailored beneficiation processes are essential to maximize extraction

What Do You Know About Ore Dressing Equipment – Hydrocyclone

The world of mineral processing has many techniques and tools, but hydrocyclones stand out. Have you ever wondered how they work or what they can do for your operation? Let’s dive into the mystery behind these fascinating devices. Hydrocyclones are vital tools in ore dressing, primarily separating solids from liquids

Single Molybdenum Ores vs. Copper-Molybdenum Ores Beneficiation

Molybdenum, discovered relatively recently as a metallic element, is a vital strategic resource. Due to its advantages, such as high strength, high melting point, corrosion resistance, and wear resistance, molybdenum finds extensive industrial applications. In China, molybdenum is classified as one of the six dominant mineral resources with relatively abundant

Trio of China Phosphate Deposits: Igneous, Sedimentary & Metamorphic

Phosphate rock, a critical non-renewable resource rich in phosphorus and primarily composed of calcium phosphate minerals like apatite, is essential for agriculture, chemicals, and advanced materials. Phosphate China, which holds the world’s second-largest phosphate reserves, features diverse deposit types—igneous apatite, sedimentary phosphorite, and metamorphic phosphorite—each presenting unique mineralogical and processing

Science and Applications of Spiral Gravity Concentrators

Gravity separation is an ancient physical separation method that uses the density difference between different minerals and external forces such as gravity to separate and extract useful minerals. Before the 1980s, gravity separation was one of the most important separation methods for mineral extraction in China. In recent years, with

How to Choose a Suitable Jig Machine When There is Not Enough Space on The Sand Dredgers?

Space on sand dredgers is limited, yet efficient mineral processing is necessary. The right jig machine makes all the difference between wasted potential and smooth operation. This guide shows you the smart solution for tight spaces. Choosing a Circular Jig solves space constraints on sand dredgers. Its compact annular design

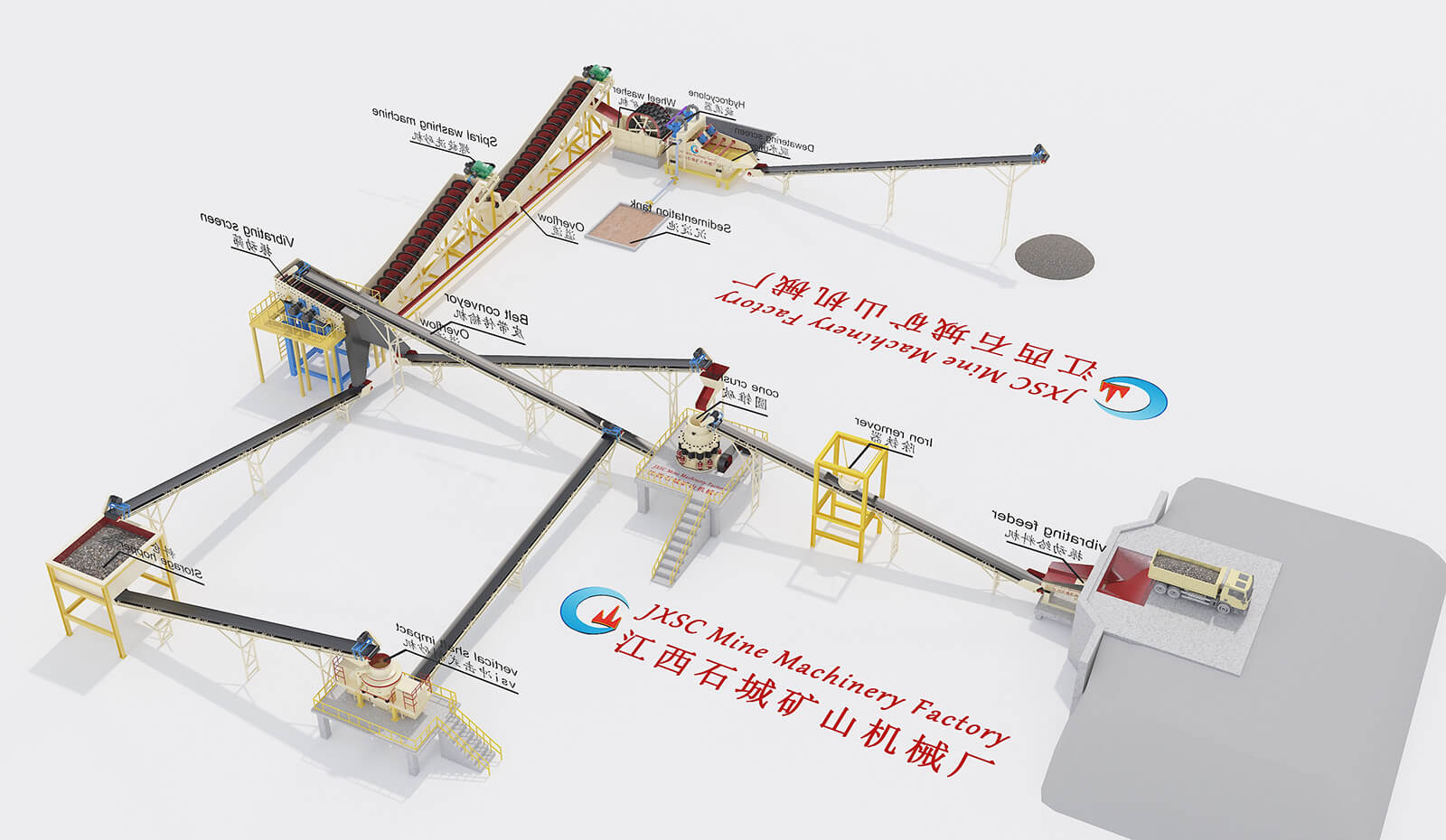

JXSC Customized 100 TPH Sand Making Plant

The increasing demand for high-quality construction materials has made manufactured sand (M-sand) a sustainable and efficient alternative to natural river sand. A 100-ton-per-hour (TPH) sand-making plant is an ideal solution for mid- to large-scale sand production, offering automation, consistent output, and environmental benefits. 100 TPH Sand Making Plant JXSC, a

Factors Affecting The Separation Effect of Spiral Chute & How to Optimize it?

The beneficiation effect of the spiral chute directly affects the technical and economic indicators of the beneficiation production line. Its separation efficiency determines the concentrate grade, metal recovery rate, and stability of the overall process. Good separation effect (such as optimizing pitch, concentration, and flushing water) can improve the grade