The determination of a gold ore processing flow is a comprehensive engineering project that requires consideration of six key factors to achieve the optimal balance of technical feasibility, economic viability, and environmental friendliness. This process involves an in-depth understanding of ore characteristics, selection of appropriate mineral processing technologies, assessment of economic feasibility, and consideration of environmental impacts across multiple dimensions. This article systematically explores the six main factors to consider when determining gold ore processing flows and their interrelationships.

1.Ore Property Analysis: The Foundation of Process Design

Physical Properties

Hardness and Toughness

The hardness and toughness of the ore directly affect the design of the crushing and grinding processes. Quartz-type gold ores are typically harder with higher grinding energy consumption, while shale-type or weathered gold ores are relatively softer and easier to crush and grind. These characteristics determine whether to choose autogenous mills, semi-autogenous mills, or ball mills, and the number of crushing stages.

Specific Gravity Characteristics

The gravity difference between gold and gangue minerals is the basis for gravity concentration. Natural gold has a specific gravity of 19.3, significantly different from most gangue minerals (specific gravity 2.5-4.0), which makes gravity separation possible. The specific gravity distribution of the ore affects the selection of different types of gravity separation equipment, such as shaking tables, hydrocyclones, or centrifugal concentrators.

Particle Size Distribution

The natural particle size distribution of the ore and its grindability influence grinding process parameters. For example, brittle oxidized ores and hard-to-grind primary ores require different grinding parameter designs. Additionally, the particle size distribution of gold particles directly relates to the selection of liberation grinding size and subsequent processes.

Chemical Composition Analysis

Gold Grade and Variation

The average gold grade of the ore and its spatial distribution determine the overall economics of the process flow. High-grade ores may allow for more complex processes, while low-grade ores require higher throughput and stricter cost control.

Associated Element Content

The presence of associated elements such as silver, copper, lead, and zinc affects process selection. For example, high copper content will increase cyanide consumption; high sulfide mineral content may necessitate flotation as a pre-selection process.

Interfering Elements Assessment

Elements such as arsenic, antimony, mercury, and tellurium affect cyanidation efficiency. High organic carbon content in “carbonaceous gold ores” can lead to the re-adsorption of gold from the leaching solution by organic carbon (known as “preg-robbing”), requiring special processes like CIL (Carbon-In-Leach) to resolve.

2.Gold Occurrence State: The Determining Factor for Process Route

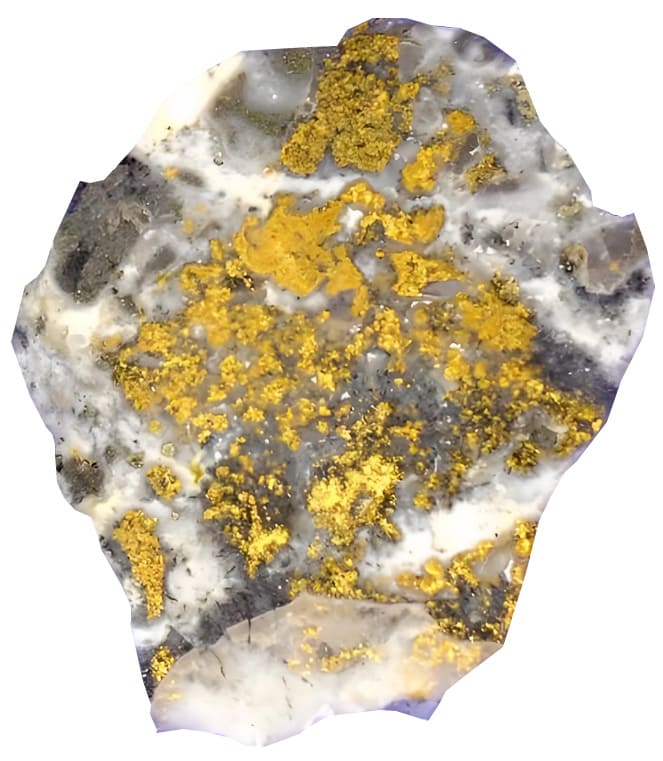

Physical Form of Gold

Natural Gold Particle Size

- Coarse gold (>74μm): Suitable for gravity separation.

- Medium-sized gold (20-74μm): Can be recovered by gravity separation or direct cyanidation

- Fine gold (<20μm): Usually requires flotation or direct cyanidation.

- Ultra-fine gold (<5μm): Often requires ultra-fine grinding and intensified leaching conditions.

Dissemination Characteristics

The dissemination pattern of gold particles, such as fracture gold, encapsulated gold, or intergranular gold, determines the liberation difficulty and optimal grinding fineness. For example, finely disseminated gold may need to be ground to -200 mesh for effective liberation, while fracture gold may be liberated under coarser grinding conditions.

Chemical State of Gold

Native Gold and Electrum

Native gold is usually suitable for traditional cyanidation processes, while electrum (Au-Ag alloy) or other gold compounds may require stronger leaching conditions or pretreatment.

Refractory Gold Ores

When gold is tightly encapsulated by sulfide minerals (such as pyrite and arsenopyrite) or exists as solid solutions, it forms so-called “refractory gold ores,” requiring oxidative pretreatment such as bio-oxidation, pressure oxidation, or roasting.

Relationship Between Gold and Carrier Minerals

Association with Quartz

When gold is closely associated with quartz, finer grinding is usually required to achieve liberation.

Association with Sulfides

When gold is closely associated with sulfides (such as pyrite and chalcopyrite), flotation is often used as a pre-selection process to concentrate gold-bearing sulfides before cyanidation.

Association with Oxide

Minerals When gold is associated with iron oxides (such as hematite, and limonite), direct cyanidation is usually applicable, sometimes combined with gravity separation processes.

3.Mineral Processing Technology Selection: The Core of Process Combination

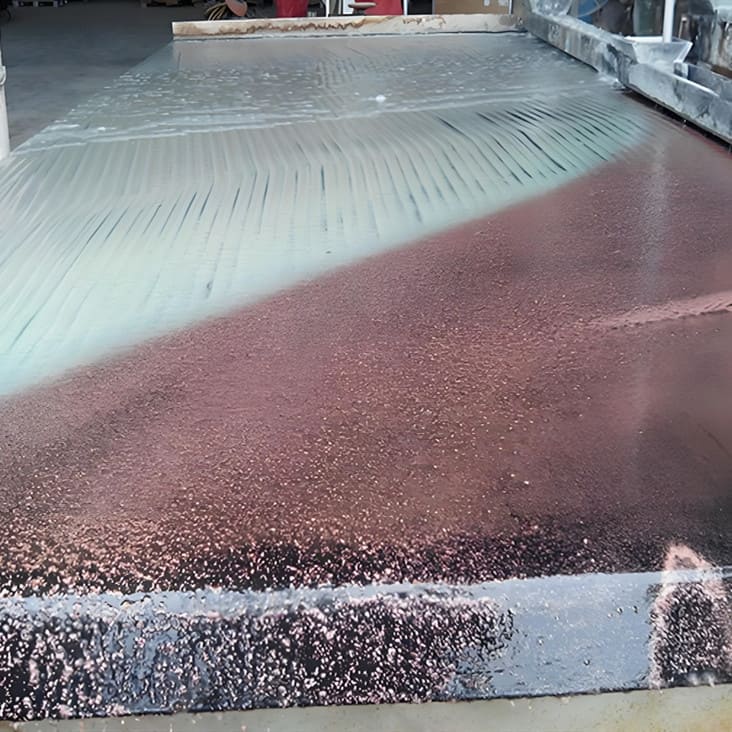

Gravity Separation Technology

Applicable Conditions

Suitable for ores containing a certain proportion of coarse native gold, especially effective when gold particles are larger than 40μm.

Equipment Selection

Select appropriate equipment based on gold particle size and ore characteristics:

- Coarse gold: Jigs, shaking tables

- Medium to fine gold: Centrifugal concentrators (such as Knelson concentrators, and Falcon centrifuges)

- Special ores: Metal detection and sorting machines (suitable for coarse nugget gold)

Position in the Process Flow

Gravity separation is usually set up in the grinding-classification closed circuit or at the early stage of grinding product treatment to recover coarse native gold as early as possible and reduce over-grinding losses.

Flotation Technology

Applicable Ore Types

Suitable for ores where gold is closely associated with sulfides, such as gold ores containing pyrite, chalcopyrite, or galena.

Reagent Regime Design

Design reagent formulations based on ore characteristics:

- Collectors: Xanthates, dithiophosphates, Z-200, etc.

- Frothers: Pine oil, methyl isobutyl ketone (MIBK), etc.

- Regulators: Lime, copper sulfate, sodium sulfide, etc.

Flotation Process Design

Design appropriate flotation processes based on ore complexity and gold dissemination characteristics:

- Basic roughing-cleaning-scavenging process

- Multiple cleaning stages to improve concentrate grade

- Multi-stage grinding and flotation for difficult-to-separate ores

Cyanidation Technology

Basic Process Selection

- Whole ore cyanidation: Suitable for most gold ores

- Heap leaching: Suitable for coarse-grained, highly permeable ores

- CIL (Carbon-In-Leach): Suitable for ores containing carbonaceous material

- CIP (Carbon-In-Pulp): Suitable for conventional ores, easier process control

Process Parameter Optimization

- Sodium cyanide concentration: Usually between 0.01-0.1%, adjusted according to ore characteristics

- Leaching time: Generally 24-72 hours, depending on the degree of liberation

- pH control: Usually maintained at 10.5-11.5 to avoid toxic HCN formation

- Oxygen supply: Stirring, aeration, or addition of peroxides to increase the dissolution rate

Pretreatment Technologies for Refractory Gold Ores

Bio-oxidation

Utilizes acidophilic bacteria such as Thiobacillus to oxidize sulfides, suitable for refractory gold ores with lower arsenic content, lower investment, and longer processing time.

Pressure Oxidation

Oxidizes sulfides under high temperature and pressure conditions (180-225°C, 1.5-3.5MPa), suitable for high-arsenic, difficult-to-treat ores, high efficiency, but a large investment.

Roasting Technology

Roasts ore at 500-750°C, suitable for high-sulfur ores, but has high environmental requirements.

4.Economic Factor Assessment: Key to Process Decision-Making

Investment Cost Analysis

Equipment Investment

Different process routes require significantly different equipment. For example, gravity separation processes have relatively lower investment, while pressure oxidation pretreatment requires specialized equipment such as autoclaves, resulting in higher investment.

Infrastructure Requirements

Cyanidation plants need to build supporting facilities such as tailings dams and detoxification systems, which are important investments to consider in process decisions.

Development Cycle

Process complexity affects the project construction period. Simple processes may be built and put into production in 1-2 years, while complex processes may require 3-5 years or longer.

Operating Cost Considerations

Energy Consumption

Grinding is typically the largest energy-consuming stage, accounting for 40-60% of total energy consumption. Different process routes have different grinding fineness requirements, directly affecting energy costs.

Reagent Consumption

The cost of main reagents such as sodium cyanide, activated carbon, and lime constitutes a significant portion of operating costs. Elements like copper and zinc in the ore increase cyanide consumption, affecting economics.

Human Resource Requirements

Complex processes require more technical personnel and higher skill requirements, increasing labor costs.

Recovery Rate and Economic Benefit Balance

Marginal Recovery Cost

Increasing recovery rates usually comes with rising costs, requiring an assessment of whether marginal revenue exceeds marginal cost. For example, improving the last 5% of gold recovery may require disproportionate costs.

Gold Price Sensitivity

Process decisions need to consider gold price fluctuation risks. In a low gold price environment, simpler low-cost processes may be needed; a high gold price environment can accept more complex but higher recovery rate processes.

5.Environmental and Social Factors: Considerations for Sustainable Development

Environmental Impact Control

Cyanide Management

Cyanidation processes require strict cyanide management and detoxification treatment, including CNWAD (Weak Acid Dissociable Cyanide) monitoring and SO2/air detoxification methods.

Wastewater Treatment Requirements

Different processes produce wastewater with different characteristics, requiring appropriately designed treatment systems to ensure discharge compliance or closed-circuit recycling.

Tailings Disposal Plans

Consider appropriate disposal methods based on tailings characteristics, such as dry stacking, conventional slurry disposal, or paste backfilling, balancing costs and environmental risks.

Sustainability Considerations

Water Resource Management

In water-scarce areas, priority may need to be given to low-water consumption processes or efficient water recycling systems.

Energy Efficiency

Optimize grinding system energy efficiency and consider potential renewable energy utilization.

Mine Closure Planning

Process selection should consider the difficulty and cost of environmental restoration after future mine closure.

6.Process Combination and Flow Optimization

Common Process Combination Models

Gravity Separation-Cyanidation Combined Process

First recover coarse gold through gravity separation, then subject gravity tailings to cyanidation treatment. Suitable for ores containing a certain proportion of coarse gold.

Flotation-Cyanidation Combined Process

Concentrate gold-bearing sulfides through flotation, then regrind and cyanide the flotation concentrate. Suitable for ores where gold is closely associated with sulfides.

Whole-Ore Cyanidation Process

The ore is directly subjected to whole-ore cyanidation after crushing and grinding. Suitable for oxidized ores or simple sulfide ores.

Pretreatment-Cyanidation Process

Refractory ores first undergo bio-oxidation, pressure oxidation, or roasting pretreatment, followed by cyanide leaching. Suitable for refractory gold ores.

Process Flow Optimization Strategies

Split Processing Strategy

Process different ore types separately based on differences in gold occurrence state. For example, separately process portions containing coarse gold through sorting.

Stage Recovery Strategy

Set up gravity separation circuits in the grinding-classification closed circuit to recover liberated gold promptly during the grinding process, avoiding over-grinding.

Pre-concentration Strategy

For low-grade bulk ores, reduce the processing volume of subsequent high-cost processes (such as cyanidation) through pre-concentration (such as flotation).

Conclusion

Determining the gold ore processing flow is a complex engineering project that requires comprehensive consideration of multiple factors. Ore properties and gold occurrence state are the basis for process selection, while technical feasibility, economic rationality, and environmental friendliness are the core criteria for decision-making. Successful process flow design needs to start from laboratory testing, through expanded trials and pilot tests, to finally determine the optimal solution.

With technological advances, the application of new environmentally friendly leaching agents (such as thiourea, chlorides, etc.), the introduction of intelligent control systems, and the development of precision metallurgy provide new possibilities for optimizing gold ore processing flows. However, regardless of how technology evolves, deeply understanding ore characteristics and selecting the most appropriate process combination based on this understanding remains the core principle in determining gold ore processing flows.