Ghana’s rich alluvial gold deposits attract miners from around the world, but the presence of sticky clay and fine gold particles presents unique challenges. For one local mining company, JXSC provided a 50TPH alluvial gold processing plant that not only addressed these challenges but also set the stage for future expansion.

This case study delves into the client’s requirements, our custom solution, and the technology behind achieving a 85-90% gold recovery rate. Discover why our trommel scrubber, centrifugal concentrator, and shaking table worked seamlessly together—and how JXSC’s 40+ years of expertise ensured success.

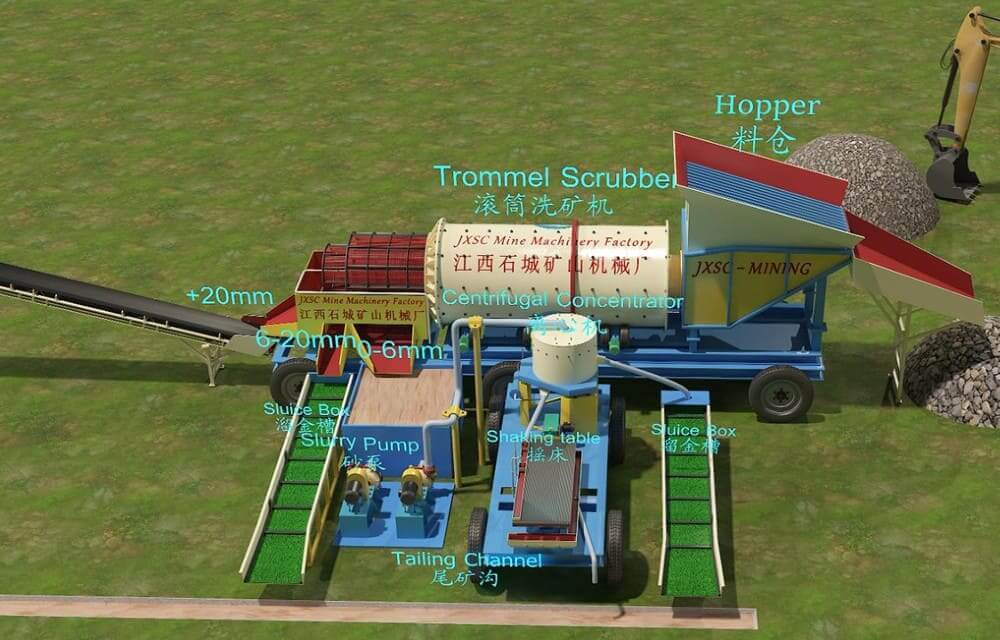

50TPH Alluvial Gold Process Plant in Ghana

1. Project Overview

This project is located in Ghana. The client is a local mining company, focusing on small-scale Alluvial gold mining. They required a reliable and easy-to-operate gold processing solution.

2. Raw Ore Information

The raw ore is alluvial gold with a maximum feed size of 150 mm. The gold particles are mainly fine gold, with sticky clay.

3. Processing Capacity Requirement

The client required a processing capacity of 50 tons per hour, with the possibility to upgrade to 100TPH or 150TPH in the future.

The Challenge: Processing sticky clay alluvium at scale.

Unlike dry mining operations, Ghana’s monsoon-heavy climate means clay sticks stubbornly to gold-bearing material. Conventional trommel screens struggled, which is why JXSC opted for heavy-duty trommel scrubbers—engineered to break up clumps before sorting.

Our Process Design & Solution

Main Equipment List:

- Trommel scrubber

- Centrifugal Gold Concentrator

- Shaking Table

- Sluice Box

- Water Pumps & Slurry Pump

- Diesel Generator & Control Panel

Process Description:

1. Loader or Excavator feed raw ore into the trommel scrubber. The trommel scrubber is to wash off clay from ore and screen out different-sized particles.

2. Overscreen materials of the trommel are transported to a far place by belt conveyor, this is waste sand.

3. Underscreen materials of the trommel are sent to the centrifugal concentrator by a slurry pump. The centrifugal concentrator is to concentrate 0-5mm fine gold.

4. Tailings of the centrifugal concentrator will be sent to the sluice box for recovering more gold.

5. Concentrates of the sluice box and centrifugal concentrator are sent to the shaking table for fine concentration of gold to increase the purity of gold content.

Customer Questions & Our Answers

1. What gold recovery rate can be achieved?

The gravity recovery rate can reach 85–90%, depending on the ore condition.

2. Why use a trommel scrubber but not use a trommel screen for washing?

We determine whether to use a trommel scrubber machine or a trommel screen based on the customer’s mining site conditions. In this customer’s case, the material at their mining site is very t sticky and is very hard to clean.

3. Why use a gold centrifuge to recover the gold first, instead of going to the shaking table directly?

The main function of the centrifuge is to initially concentrate the gold concentrate.

Because a single shaking table only has a processing capacity of 1-2 tons per hour, and this customer has a relatively large processing volume, using shaking tables after washing would require many shaking tables to meet their processing needs. Therefore, we recommend using a centrifuge to initially concentrate the gold concentrate.

4. Can you provide the flowchart drawing before the order?

Yes, before placing an order, our engineers will design a suitable process flowchart based on the customer’s mining site conditions. And once we receive your deposit payment, our engineer will design the detailed plant layout drawing, foundation drawing for you, and also each main machine’s drawing & machine operation manual.

All the technical support will be provided to assist with the installation.

5. Do your products have CE or ISO certificates?

Yes, all the equipment in this order has CE certificates and ISO certificates.

6. Could you tell me the approximate replacement cycle for the wear parts?

Yes, we can provide an estimated replacement cycle for wear parts.

7. Why is a sluice box needed to recover the tailings of gold centrifugal?

Because the client said they wanted to recover as much gold as possible, we suggested they use a sluice box to process the tailings from the centrifuge, which would maximize the recovery of more gold.

Manufacturing, Delivery & Installation Photos

Why Clients Trust JXSC?

✅ Customized processing solution

✅ The company is ISO certificate approved, and the products have CE approval.

✅ Installation & technical support

✅ 40 years of manufacturer history of all kinds of mining machinery (including crushing plant &mineral processing plant)

Client Feedback:

The client is satisfied with the plant performance and gold recovery results. The system operates stably and meets the expected production target.

Is This Plant Right for You?

This 50TPH alluvial gold rocess plant suitable for:

✅ Small to medium-scale gold mining projects

✅ Alluvial gold with stick clay and without sticky clay

✅ Capacity from 50-100TPH

Not suitable for:

❌ Rock gold process plant

❌ Very large-scale industrial plants

Contact our engineers for a customized flowsheet based on your ore assay!

Conclusion: More Than Just a Gold Plant—A Long-Term Investment

JXSC’s 50TPH Ghana gold plant proves that smart engineering overcomes sticky challenges. By combining trommel scrubbers, centrifuges, and shaking tables, we delivered high recovery with scalability—perfect for miners looking to grow sustainably.

Want a custom solution? Contact JXSC today for tailored alluvial gold processing designs.