The quest for gold extraction efficiency continues to drive innovation in mineral processing. Among the arsenal of available technologies, heap leaching and Carbon-in-Leach (CIL) have emerged as fundamentally different approaches catering to distinct mining scenarios. This technical breakdown examines these two industry-standard methods through four critical lenses: application, efficiency, cost, and environmental impact. Whether you’re evaluating a marginal deposit or optimizing an existing operation, understanding these key differences will inform smarter processing decisions and maximize resource value.

Heap Leaching

Heap leaching is a hydrometallurgical process used to extract precious metals (mainly gold, silver, and copper) from low-grade ores by percolating a leaching solution through stacked material. It allows economical recovery from ore grades as low as 0.5 g/t Au, making it ideal for marginal deposits or tailings reprocessing.

Process Principle

A gold extraction method based on leaching. Crushed ore is piled into heaps, and cyanide solution is sprayed from the top. The solution permeates the ore pile from top to bottom, dissolving gold, which is ultimately recovered from the collected leachate.

Gold Extraction Process Flow

Raw ore → Crushing (to specified size) → Heap formation → Spray leaching → Precious liquid collection → Activated carbon adsorption/zinc powder replacement → Gold recovery.

Core Advantages

This process eliminates the energy-intensive grinding stage, offering significant benefits including lower investment, reduced operating costs, and shorter construction cycles. It is particularly well-suited for processing low-grade, highly permeable oxidized gold ores.

Limitations

- Lower recovery rates (~60-75%)

- Slow kinetics (weeks-months)

- Sensitive to clay content & permeability

- Higher cyanide consumption (if not optimized)

- Environmental risks (cyanide leakage)

- Weather-dependent (temperature/rainfall)

Modern Applications

Heap leaching is widely used for:

- Low-grade oxide gold ores

- Small-scale & artisanal mining cleanup

- Reprocessing old tailings

- Copper/molybdenum/silver extraction

Heap Leaching Process Flow

Here’s a streamlined overview of modern heap leaching operations with integrated best practices:

1. Ore Preparation Stage

- Primary crushing (when processing coarse ore >25mm)

- Agglomeration drum treatment (binding fines with 2-5kg cement/tonne + lime for pH modification)

2. Heap Construction Phase

- Conveyor stacking on engineered pads (3-10m height optimal per lift)

- Liner systems (HDPE geomembrane + clay composite)

3. Chemical Leaching Cycle

- Cyanide application (0.2-1.0g NaCN/L at pH 10.5±0.5) via drip emitters

- Controlled percolation (5-10L/hour/m² typical flow rate)

4. Metal Recovery System

- Pregnant solution collection (0.5-3ppm Au concentration)

- Carbon adsorption columns (or Merrill-Crowe zinc precipitation)

- Barren solution recirculation (90%+ reuse efficiency)

Key Process Enhancements

- Pre-aeration for refractory ores

- Multi-lift stacking for improved permeability

- Real-time cyanide monitoring

- Segmented pads for continuous operation

Carbon-in-Leach (CIL) Process

The Carbon-in-Leach (CIL) process is an advanced gold extraction method that combines leaching and adsorption into a single circuit, widely used in large-scale mining operations for high recovery rates (>90%).

Process Principle

The mainstream technology in modern gold mineral processing. Cyanide leaching and activated carbon adsorption occur simultaneously in tandem stirred reaction tanks, achieving highly efficient gold recovery. This process requires gold minerals to be sufficiently liberated through grinding.

Complete Gold Recovery Workflow

Raw ore → Crushing → Grinding (to fine powder) → Slurry Preparation → CIL Leaching/Adsorption → Gold-loaded Carbon Desorption/Electrolysis → Gold Slime Smelting. This constitutes a complete whole-slime cyanidation process.

Core Advantages

High recovery rates, mature and stable technology, and strong adaptability to ore types. It serves as the standard solution for processing primary ores with fine-grained or ultrafine-grained gold distribution, complex sulfide ores, and higher-grade ores.

Limitations

- High capital cost (ball mills, tanks, carbon handling)

- Requires fine grinding (energy-intensive)

- Sensitive to organic carbon (“preg-robbing” ores)

- Higher cyanide use vs. heap leaching

Carbon-in-Leach (CIL) Process Flow

1. Ore Preparation

Crushing & Grinding: Run-of-mine ore is crushed and ground to a fine particle size (~75 μm) to maximize gold liberation.

Slurry Formation: Ground ore is mixed with water to form a pumpable slurry (~40–45% solids).

2. Leaching & Gold Adsorption (CIL Tanks)

Cyanide Leaching:

- Sodium cyanide (NaCN, 0.01–0.05%) dissolves gold (Au → Au(CN)₂⁻) under oxygen-rich conditions (air/O₂ injection).

- Maintained at pH 10.5–11.0 (lime/sodium hydroxide) to ensure safety and efficiency.

Carbon-in-Leach (CIL):

- Activated carbon (6–20 mesh) is added directly into the leaching tanks.

- Gold cyanide complexes adsorb onto carbon granules as leaching occurs (eliminating the separate adsorption stage).

- Slurry flows sequentially through 6–9 tanks (total retention time: 24–48 hours).

3. Carbon Handling & Gold Recovery

Loaded Carbon Separation: Screens/interstage filters separate gold-loaded carbon from slurry.

Carbon Stripping (Elution):

- Carbon undergoes acid washing (removes impurities) followed by high-temperature elution (~130°C, NaOH/NaCN solution).

- Gold desorbs into solution (~98% efficiency).

Electrowinning:

- Gold-rich eluate is pumped through electrowinning cells.

- Gold plates onto steel wool cathodes (Au⁺ → Au⁰).

Smelting: Cathode sludge is melted (~1,100°C) with fluxes (borax/silica) to produce gold-silver doré bars.

4. Carbon Regeneration & Tailings Treatment

Carbon Reactivation: Stripped carbon is thermally regenerated (~700°C) to restore adsorption capacity.

Tailings Detoxification: Residual cyanide in tailings is destroyed (SO₂/air, H₂O₂) before safe disposal in tailings storage facilities (TSF).

Heap Leaching vs. Carbon-in-Leach (CIL)

Here’s a structured comparison of these two gold extraction methods:

1. Process Overview

| Feature | Heap Leaching | Carbon-in-Leach (CIL) |

| Method | Low-grade ore stacked & irrigated with cyanide solution | Ground ore leached in tanks with activated carbon |

| Best For | Low-grade ore (<1 g/t Au) | Higher-grade ore (typically >1 g/t Au) |

| Scale | Suitable for small to massive operations | Primarily large-scale operations |

| Recovery Time | Weeks to months | Hours to days |

2. Recovery Efficiency

| Factor | Heap Leaching | CIL |

| Typical Recovery | 60–75% | 90–98% |

| Sensitivity to Ore Type | Struggles with clayey/fine ores | Handles most ore types well |

| Impact of Preg-Robbing | Gold lost to carbonaceous material | Carbon adsorption prevents preg-robbing losses |

3. Operational Requirements

| Aspect | Heap Leaching | CIL |

| Grinding Needed? | No (crushed only) | Yes (to ~75 μm) |

| Carbon Handling | None | Requires regeneration/recycling |

| Chemical Usage | Cyanide only | Cyanide + activated carbon |

| Automation Level | Low | High |

4. Economic Considerations

| Factor | Heap Leaching | CIL |

| Capital Costs | Lower | Higher (due to grinding, tanks, carbon systems) |

| Operating Costs | Lower (~$10–25/oz) | Higher (~$20–50/oz) |

| Payback Period | Longer (due to slower leach kinetics) | Shorter (faster recovery) |

| Labor Intensity | Lower | Higher |

5. Environmental Considerations

| Factor | Heap Leaching | CIL |

| Cyanide Consumption | Higher (due to longer exposure) | Lower (controlled leaching) |

| Tailings Risks | Higher (large heap footprint) | Better containment |

| Water Usage | Higher (evaporation losses) | Recycled in circuit |

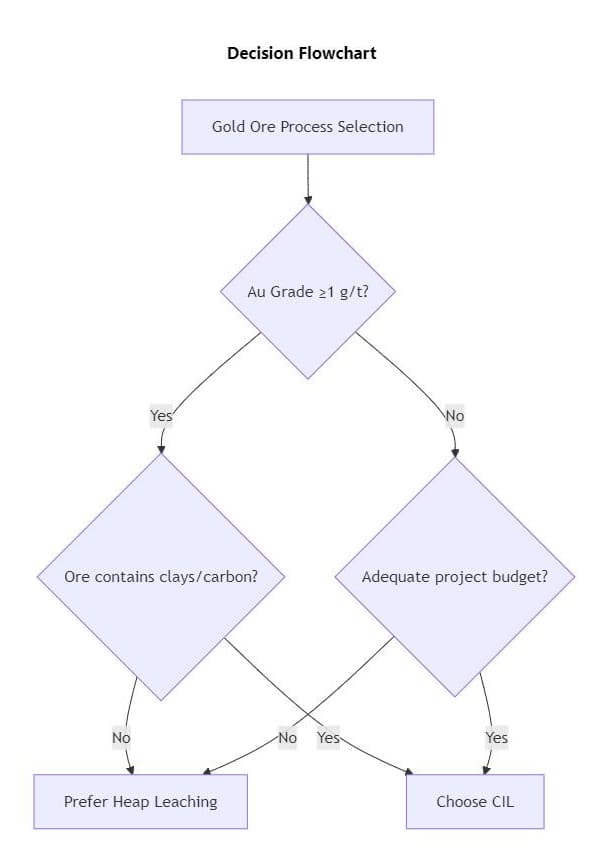

Which Should be Chosen: Heap Leaching or CIL?

When selecting gold ore processing methods, the choice between heap leaching and carbon-in-leach (CIL) processes primarily hinges on two core factors: ore characteristics and economics. Heap leaching offers low costs and simple operation, making it suitable for treating low-grade (typically <1 g/t) oxidized ores with good permeability. However, it yields relatively low recovery rates (60-75%) and is significantly affected by weather conditions. Conversely, CIL efficiently processes medium-to-high grade (>1 g/t) or complex ores through fine grinding and continuous activated carbon adsorption, achieving recoveries exceeding 90%. However, its capital and operational costs are significantly higher.

Practical selection also requires balancing environmental regulations and project conditions. In arid regions, heap leaching presents minimal water evaporation issues. For ores containing clay or carbonaceous materials, CIL better prevents gold loss. For small-to-medium-sized low-grade mines, heap leaching offers clear economic advantages; large high-grade projects typically favor CIL to maximize returns. Where necessary, hybrid approaches can be adopted—processing high-grade ore via CIL and low-grade ore via heap leaching—to achieve tiered resource utilization.

Conclusion

Ultimately, the heap leaching versus CIL decision transcends simple technical preference – it represents strategic alignment between ore characteristics and economic objectives. While heap leaching unlocks value from low-grade deposits with its streamlined infrastructure, CIL delivers premium recovery for higher-grade resources despite greater capital intensity. Contemporary operations increasingly blend these approaches through split-ore processing strategies, demonstrating that the most profitable solution often lies in methodical integration rather than exclusive selection. As gold projects face tightening margins and stricter environmental standards, this comparative framework provides miners with the essential criteria for making evidence-based extraction choices.