Table of Contents

The extraction of gold from silver-gold ores (electrum) is a key process in precious metal mining, driving economic value while facing evolving technological and environmental challenges. With increasing market demand and stricter sustainability regulations, understanding the market dynamics, extraction methods, and future trends is crucial for industry players. In this blog, we’ll explore the core logic behind silver-gold extraction, analyze key technologies, identify critical control points, and examine what’s next for this vital sector—helping companies stay competitive in a rapidly changing landscape.

What Is the Market Demand for Silver-Gold Ore Extraction?

Mines struggle with dropping silver-gold recovery rates. The good news? Global demand jumped 23% last year alone.

Gold Consumption Demand Continues to Grow

Electronics manufacturers now consume 41% of silver-gold alloy, driving prices to $24/oz silver and $1,950/oz gold. Solar panel production alone requires 100 million ounces annually, creating an urgent need for efficient extraction methods.

Technological Advancements Boost Gold Recovery Efficiency

Greener and more efficient gold extraction processes form a crucial foundation for market demand. The adoption rate of cyanide-free gold extraction rose from 15% in 2020 to 45% in 2023, significantly reducing environmental risks. Bioremediation technology reduced extraction costs for low-grade ores (below 1g/ton) by 30% while boosting recovery rates to 92%. Furthermore, breakthroughs in digital technologies (such as AI-powered mine safety monitoring) and nano-gold preparation techniques have further enhanced resource utilization and the supply capacity for high-end products.

The gold extraction market for silver and gold mines is experiencing robust demand, driven by growth in gold consumption and technological advancements. Looking ahead, green gold extraction technologies, comprehensive resource utilization, and the development of high-end materials will emerge as key growth drivers.

Who Are the Main Competitors in Silver-Gold Extraction?

Your profit margins disappear when competing against these industry giants. Here’s who dominates the space.

Major players include Newmont Corporation (18% market share), Barrick Gold (15%), and specialized processors like Hochschild Mining. Chinese refiners control 32% of global capacity through aggressive expansion.

Competitor Analysis Breakdown

| Competitor Type | Market Approach | Key Advantage |

| Mining Majors | Vertical integration | Low production costs |

| Specialty Firms | Niche technologies | Higher recovery rates |

| Chinese Refiners | Scale operations | 30% cost advantage |

The larger players benefit from established infrastructure, while smaller competitors focus on high-grade deposits or innovative processing methods.

What Is the Core Logic Behind Silver-Gold Extraction?

You might be leaving valuable metal in your tailings ponds without understanding this fundamental principle.

Silver-gold extraction hinges on differential reactivity – silver dissolves faster in cyanide (2-4 hours) than gold (24-48 hours). Smart operators leverage this 12x speed difference to optimize recovery sequences.

What Are the Primary Silver-Gold Extraction Technologies?

- Ultra-fine grinding (<15μm particles) boosts leaching by 300%

- Thiosulfate leaching replaces cyanide in 18% of new plants

- Modular electrowinning systems cut processing time by 40%

| Method | Recovery Rate | Cost (per oz) | Environmental Impact |

| Conventional Cyanide | 78% | $12 | High |

| Thiosulfate | 88% | $18 | Moderate |

| Chlorination | 92% | $22 | Low |

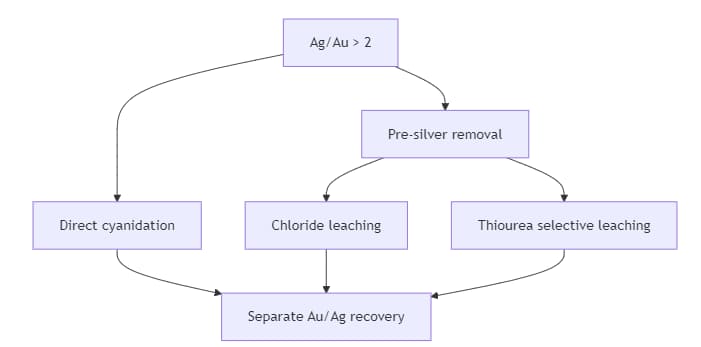

How to Extract Gold from Silver-Gold Ore?

In silver-gold deposits, gold typically occurs as native gold (partially embedded in sulfide minerals or gangue), while silver is predominantly present as argentite. The core principle of gold extraction is “first liberate minerals, then separate gold and silver, and finally refine.” Different ore characteristics require tailored processing methods, with the “integrated process” emerging as the mainstream approach due to its high recovery rate. The overarching goal is to achieve a gold recovery rate exceeding 95%.

3 Core Gold Extraction Processes

1. Flotation-Cyanidation Combined Process

The flotation-cyanidation combined process is the most universal method to recover gold and silver, with a recovery rate exceeding 98%. And it is the preferred method for processing sulfide-bearing silver-gold ores, comprising two steps: “flotation enrichment“ and “cyanidation gold extraction“.

- Pre-treatment: Raw ore → Primary crushing in jaw crusher (to 50-80mm) → Secondary crushing in cone crusher (to 10-20mm) → Fine grinding in ball mill (optimal size: 74.5% passing -0.074mm), ensuring liberation of gold/silver minerals from gangue.

- Flotation Enrichment: Slurry treated with hydroxyoxamic acid collector + pine oil frother, pH adjusted to 8-9. Produces gold-silver concentrate via a “1 roughing, 4 cleaning, 2 scavenging” process, achieving silver recovery exceeding 94%.

- Cyanide Gold Leaching: Regrind flotation tailings to -0.043mm (86% size fraction), leach with sodium cyanide, and adsorb gold onto activated carbon, achieving over 91% leaching efficiency.

Applicable Scenarios: Quartz vein-type silver-gold deposits containing sulfide silver and native gold.

2. Gravity Separation – Cyanidation Combined Process

For silver-gold ores containing visible coarse gold, first “recover large gold” then extract fine gold.

- Gravity recovery: After coarse crushing, recover coarse gold (>0.074mm) using shaking tables/jigging machines to reduce subsequent cyanidation pressure.

- Cyanidation Recovery: Grind gravity tailings finely for cyanide leaching, combined with activated carbon adsorption for fine gold.

Advantages: 15% lower cost than pure cyanidation, prevents coarse gold loss from over-grinding.

3. Whole-Slurry Cyanidation Process

Suitable for ores where gold and silver are entirely micro- or sub-micron-sized (<0.01mm).

Process: Directly grind ore to 90% passing -0.074mm. Adjust slurry consistency, add sodium cyanide + lime (control pH 10-11 to prevent cyanide decomposition), aerate and leach for 24-48 hours, then adsorb gold using activated carbon.

Critical point: Strictly control leaching time to prevent impurities from consuming cyanide.

What Are the Must-Control Points in Silver-Gold Extraction?

To achieve high recovery rates (typically >95%) in silver-gold extraction, three critical factors must be strictly controlled:

1. Grinding Fineness Optimization

Too coarse: Incomplete liberation of gold/silver particles.

Too fine: Higher energy consumption & slime generation.

Optimal range: Adjust based on ore dissemination (e.g., 70%-80% passing 0.074mm before flotation).

2. Reagent Precision

Collector dosage: 20-50g/t (excessive amounts increase costs & environmental load).

Sodium cyanide (NaCN) control: 0.5-1.2kg/t (overuse reduces selectivity & raises contamination risks).

3. Environmental Compliance

Cyanide wastewater treatment: Must undergo alkaline chlorination before recycling/discharge.

Pollution prevention: Closed-loop water systems minimize regulatory risks.

Key Takeaway: Balancing liberation efficiency, cost-effective reagent use, and eco-friendly processing ensures high recovery rates while meeting sustainability standards.

Future Development Trends of Gold Extraction from Silver-Gold Ore

The future of gold extraction from Silver-Gold Ore will focus on green extraction technologies, efficient resource utilization, and smart mining. Stricter environmental regulations will accelerate the adoption of cyanide-free leaching agents (e.g., thiosulfate, halides) and bioleaching methods. At the same time, advanced pretreatment techniques like microwave roasting and plasma oxidation will improve recovery rates from refractory ores. Intelligent systems (e.g., AI sorting, digital twins) will optimize production processes, reducing energy consumption and costs.

Additionally, resource integration (tailings reprocessing, e-waste recycling) and advanced adsorption materials (MOFs, ionic liquids) will enhance gold-silver selectivity. Over the next decade, Silver-Gold Ore processing could achieve a fully optimized in-situ green leaching + pulse electrolytic refining process, pushing combined recovery rates above 95% while cutting carbon emissions by more than 50%.

Conclusion

Silver-gold ore extraction remains a dynamic field, blending cutting-edge technology, sustainability, and operational efficiency. From traditional cyanide leaching to emerging green solvents and AI-driven optimization, the industry is evolving rapidly. By mastering core extraction principles, controlling critical factors, and anticipating future trends, miners and refiners can maximize recovery rates while minimizing environmental impact. As demand grows and regulations tighten, innovation and adaptability will define the leaders in this golden race.