With over 40 years of experience in mineral processing, JXSC Mine Machinery has established itself as a trusted Mining Equipment OEM & ODM based in China. We specialize in providing sustainable minerals processing solutions, from customized equipment to complete end-to-end plant designs for global clients.

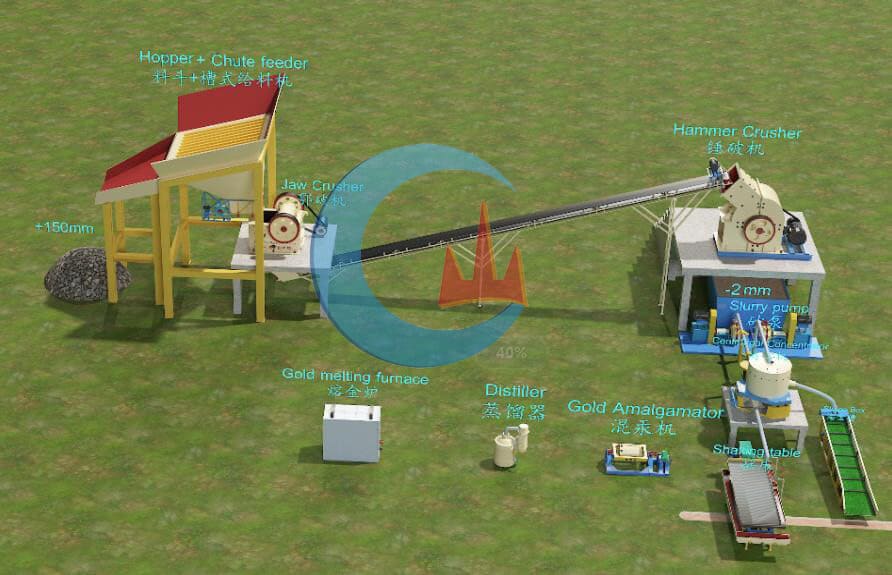

One of our recent success stories is a 5-ton-per-hour (TPH) hard rock gold processing plant delivered to Zambia. This case study explores how our team designed an efficient, cost-effective solution tailored to our client’s needs—showcasing JXSC’s expertise in optimized gravity separation for small-scale gold miners.

5 TPH Hard Rock Gold Processing Plant in Zambia

Section 1: Client Background & Customized Solution

Our Zambian client operates a quartz-hosted gold deposit where raw ore particles average 200mm in size. After thorough analysis, JXSC engineers confirmed that crushing to 2mm effectively liberated gold, making gravity concentration the ideal method.

Customer’s Rock Stone Gold Project Information:

- Rock stone mine location: Zambia

- Raw ore condition: Hard Quartz stone, most stone sizes are around 200mm, crush at 2mm can release the inside gold from the rock.

- Customer’s main requirements: 5tph as a small start, higher recovery rate.

Key Challenges Addressed:

- Hard rock crushing – Selected robust jaw + hammer crushers for high efficiency.

- Water scarcity – Designed a closed-loop system minimizing consumption (~70m³/hr).

- Small footprint – Compact layout suited for remote mine sites.

As an OEM/ODM leader, we prioritize solutions that combine reliability + scalability.

Section 2: JXSC’s Proven Processing Flowsheet

Processing Flowsheet

Stage 1: Crushing Circuit

- JXSC Chute Feeder (600×500): Ensures steady ore supply (prevents bottlenecks).

- JXSC Jaw Crusher (PE250×400): Reduces 200mm ore to ≤60mm—durable for hard quartz.

- JXSC Hammer Crusher (PC600×400): Pulverizes to ≤2mm efficiently (vs. ball mill).

Stage 2: Gravity Gold Recovery

- JXSC Centrifugal Concentrator (STLB60): Achieves 60–70% recovery in first pass.

- JXSC Shaking Table (6S-4500): Upgrades concentrate to 85–90% purity.

The solution is designed based on the client’s mining conditions and requirements. It is configured with a hopper, and under the hopper, connects with one chute feeder to feed materials into the jaw crusher more evenly.

1. The jaw crusher crushes the big stone size, less than around 60mm, and the output will be transported to the hammer crusher via belt conveyor.

2. The first crushed material goes to the hammer crusher. Hammer crusher grinds materials to be fine less than 2mm.

3. The 2mm material goes to the gold centrifugal concentrator for enriching and concentrating gold first.

4. Tailings of the centrifugal concentrator go to the sluice box for recovering more gold.

6. Concentrates of centrifugal concentrator and sluice box are sent to the shaking table for concentrating gold.

The Main Machines include the following:

| Item | Model | QTY(set) |

| Chute Feeder | 600*500 | 1 |

| Jaw Crusher | PE250*400 | 1 |

| Belt Conveyor | B500*20 | 1 |

| Hammer Crusher | PC600*400 | 1 |

| Gold Centrifugal Concentrator | STLB60 | 1 |

| Sluice Box | 1*4m | 1 |

| Shaking Table | 6S-4500 | 1 |

| Water Pump | IS60 | 1 |

| Water Pump | IS80 | 1 |

Our equipment is field-tested across Africa—engineered for harsh conditions.

Section 3: Customer Questions & Our Answers

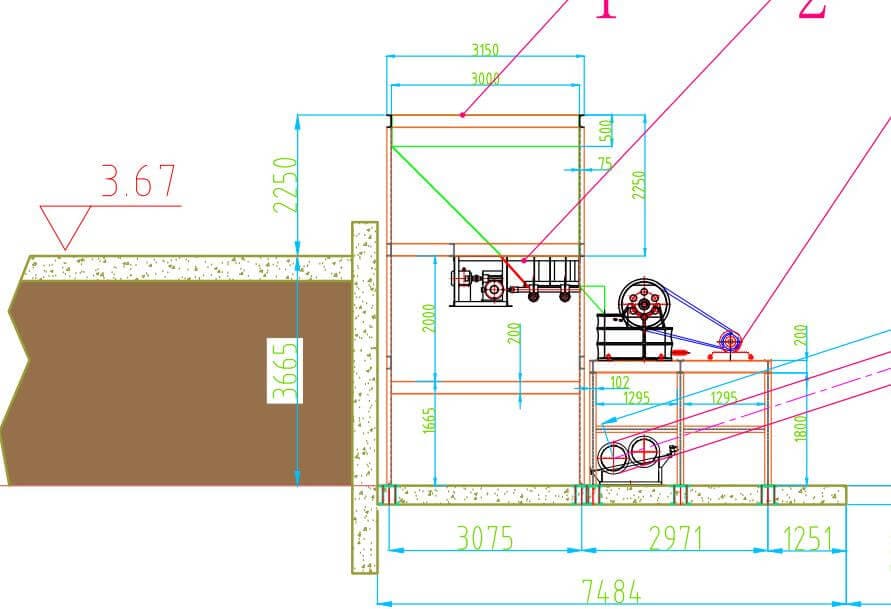

1. How to make the feeding hopper?

The drawing of the hopper will be offered after the order; the customer can weld the hopper on the mine site based on the drawing using steel plates.

2. What is the particle size requirement for the feed ore?

Based on the raw feeding capacity of 5 tons per hour, the particle size should meet the maximum feeding size of the feeder and jaw crusher, which should be below 200mm.

3. Why do you use a hammer crusher instead of a ball mill?

Because the ball mill is more suitable for fine gold recovery, if crush at 2mm can release the inside gold from the rock efficiently, and the hammer crusher is more suitable. Their has screen mesh under the hammers to make sure the output size is 0-2mm.

4. What’s the function of the centrifugal concentrator?

The centrifugal concentrator is for pre-concentrating the gold from the 0-2mm slurry of the hammer crusher.

5. What’s the function of the shaking table?

The shaking table for re-concentrating the gold concentrate from the centrifugal concentrator to reach a higher purity.

6. What gold recovery rate can be achieved?

The gravity recovery rate can reach 85–90%, final result will depend on the ore condition.

7. What’s the water consumption of the whole line of machines? The total water consumption will need approximately 70 m3 per hour, mainly the backwash water for the centrifugal concentrator and feeding water for the hammer crusher and shaking table.

8. Can you provide the civil foundation drawing of the complete machine line?

Once we receive your deposit payment, our engineer will design the detailed plant layout drawing, foundation drawing for you, and also each main machine’s drawing & machine operation manual. All the technical support will be provided to assist with the installation.

Section 4: 5 TPH Hard Rock Gold Processing Plant in Zambia Image Gallery

Why Clients Trust JXSC?

✅ End-to-End Support: From flowsheet design to commissioning (foundation drawings + manuals included).

✅ 40+ Years R&D: Optimized crushers + concentrators for hard rock & alluvial gold.

✅ Sustainable Designs: Water recycling + low-energy consumption.

Client Feedback:

“JXSC’s team nailed the balance of recovery rate + affordability. Their post-sale guidance was invaluable.”

Is This Plant Right for You?

This 5TPH system balances simplicity and high recovery, ideal for:

✅ Small mines with hard quartz ore.

✅ Operators prioritizing low Capex & easy maintenance.

✅ Sites with limited infrastructure (solar/hybrid power compatible).

Contact our engineers for a customized flowsheet based on your ore assay!