During the lead-zinc ore flotation process, controlling the froth layer and observing the froth state are key operational steps that directly impact concentrate grade and recovery. The following is a professional operating guide.

Control of Foam Layer Thickness & Scraping Volume During Each Operation

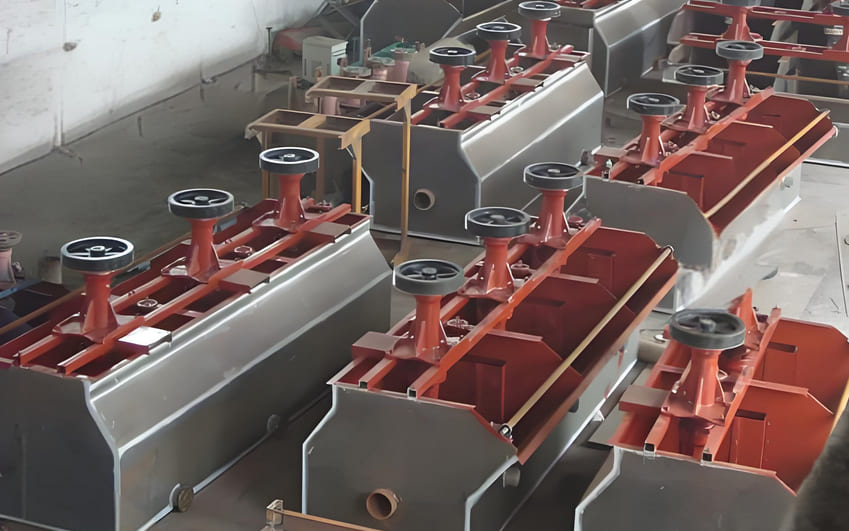

The froth layer is where flotation products accumulate, and its thickness has a direct impact on recovery and concentrate grade. The thickness of the froth layer is determined by objective factors such as ore grade and operating conditions. During operation, it is adjusted using factors such as the flotation machine’s ore loading gate, oil reagent, and slurry concentration. In actual operation, the thickness of the froth layer should be controlled based on technical specifications and the characteristics of each operation.

- In concentrate operations, a thicker froth layer is required to ensure high-quality concentrate.

- In roughing and scavenging operations, a thinner froth layer is required to maximize the recovery of less floatable minerals and some intergrowths.

Froth scraping volume is a critical operational factor. In production, separation performance is ultimately determined by the quantity and quality of concentrate scraped (i.e., foam scraping volume). In addition to being determined by froth layer thickness, foam scraping volume is also related to the balance and stability of the entire flotation process. The flotation process operates within a predetermined ore processing capacity and rated flotation cell volume. The ore aggregate volume entering flotation and the flotation time should also be stable. However, in actual production, factors such as ore properties and processing capacity vary, and the amount of foam scraped off in the final concentrate depends on the amount of foam scraped off in each operation. Therefore, strict control of foam scraping off is crucial in each flotation operation to ultimately obtain a qualified concentrate and achieve a high recovery rate. It is important to note that unilaterally increasing the amount of foam scraped off is detrimental to the flotation process, a point often overlooked by inexperienced operators. While increasing the amount of foam scraped off may appear to improve metal recovery, it is important to consider that the flotation process is an integrated process, with interdependent influences and constraints. Increasing the amount of foam scraped off in each operation not only tends to introduce a large amount of gangue into the product, reducing the quality of the foam product, but also increases the amount of middlings recycled, resulting in a corresponding shortening of the flotation time – a counterproductive effect.

Specific Operation Method of Lead-zinc Ore Flotation

To maintain a stable foam product and slurry output during each operation of the lead-zinc ore flotation process, the specific operational procedures can be summarized as follows:

- Promptly identify and investigate the causes of changes in foam layer thickness and foam scraping volume, and make appropriate adjustments.

The flotation machine scraping product should be mineralized foam; scraping slurry is generally not permitted. The slurry gate or yoke valve in the flotation machine’s intermediate chamber is used to regulate and control the foam layer thickness and foam scraping volume. The operator can make appropriate adjustments based on actual conditions. However, simply adjusting the loading gate will not eliminate the causes of sudden changes. Frequent, blind adjustments during operation can actually undermine the stability of the flotation process. In fact, many factors affect scraping volume fluctuations: if the slurry concentration fluctuates, the grinding and classifying operator should be contacted promptly; if the reagent dosage is inappropriate, the reagent dosage should be adjusted promptly. Significant adjustments to the slurry gate should only be made in abnormal situations, such as slurry overflow or a sudden drop in the ore liquid level. - Focus on observing and monitoring changes in froth thickness and scraping volume in the concentrate output cell and the first few rougher cells.

Because these flotation cells contain a large amount of valuable minerals, their flotation and froth mineralization are generally more sensitive to changes in process factors. Therefore, mastering the operation of these cells is key to achieving optimal flotation process indicators. As the metal content in the main flotation process (roughing and scavenging) decreases, the froth scraping volume should be reduced accordingly. - Adjustments to the loading gates should generally begin at the rear and progress forward.

This maintains a relatively stable slurry volume and minimizes impacts on subsequent operations. Suppose a sudden change in the grading overflow causes a change in the flotation cell scraping volume. In that case, adjustments should be made starting at the head of the flotation cell to eliminate the anomaly quickly. - Maintain a thick foam layer during the concentrating process, and the scraping volume should be consistent with the concentrate quality requirements.

In the roughing and scavenging processes, excessive foam scraping should be avoided, preferably without scraping slurry.

Observation of Flotation Foam

One of the most crucial skills in flotation operations is observing foam. Experienced flotation operators can identify operational problems and the causes of these changes based on the various apparent phenomena of the foam, allowing them to promptly adjust relevant factors and optimize the flotation process.

Observing foam mineralization should focus on flotation cells exhibiting significant changes. These include the final concentrate output cell, the first few roughing cells, the various dosing cells, and the tail of the scavenging process.

The various appearances of mineralized foam are primarily determined by factors such as the type, quantity, particle size, color, and luster of the minerals adhering to the foam surface. These factors are directly related to the location and dosage of flotation reagents added.

The degree of foam mineralization observed on the foam surface reflects the adhesion of mineral particles within the ore charge to the bubbles. The more useful minerals adhere to the bubble surface, the more characteristic physical properties of that useful mineral, such as color and luster, will be apparent.

Also, the orderly merging and collapse of bubbles on both sides of the foam layer can be a useful indicator. When the froth is well-mineralized and contains a large amount of minerals, it easily breaks. When scraped out and dropped into the froth tank, it produces a rhythmic “sand” sound. Conversely, the sound is weak and lacks rhythm.

Flotation reagents have a direct impact on the degree of froth mineralization. Excessive amounts of reagents (especially regulators and inhibitors) often result in froth that is too large, too small, or too brittle. Insufficient reagents can lead to unstable bubbles in the froth layer due to their easy merging.

When observing flotation froth, key monitoring areas include the concentrate output trough, the first three rougher troughs, before and after the dosing point, and the scavenger tail trough. Observation requires both visual and auditory evaluation: a strong metallic luster in the froth indicates good mineralization and appropriate reagent content; uneven bubble size indicates uneven mineralization and reagent imbalance; and rapid bubble collapse indicates a high mineral load in the concentrating zone. A rustling sound indicates normal mineralization (mineral content >30%), while a clattering sound warns of insufficient mineralization. Measuring bubble diameter accurately assesses froth status: Empty bubbles >3mm in diameter have minimal mineral adhesion, while solid bubbles 1-2mm in diameter have >70% mineral coverage. Pay particular attention to the transition in froth color from metallic to gray, a crucial indicator of the transition zone in determining mineralization.

Suggestions for Optimizing Lead-zinc Ore Flotation Operations

Establish Standardized Operations

- Record the foam state every 30 minutes.

- Establish a foam thickness-grade correspondence curve.

- Establish a baseline value for the amount of foam scraping for different ores.

Process For Handling Abnormal Situations

(1) Immediate measures

- Adjust the gate opening (±10% range)

- Temporarily increase or decrease the reagent dosage by 5-10%

(2) Subsequent processing

- Sampling and testing to confirm the effect.

- Notify the previous process to make adjustments.

- Record abnormal phenomena and handling results

Advanced Techniques

- Calculate bubble load rate: Estimate the amount of ore carried by foam.

- Foam stability test: Record the complete rupture time.

- Reagent impact test: Establish a reagent-foam phase relationship spectrum.

Mastering these foam control techniques can increase lead-zinc ore flotation recovery by 3-5% while reducing concentrate interconcentration by 1-2 percentage points. It is recommended that new employees complete at least 200 hours of foam observation training before being able to independently operate key positions.