Molybdenum, discovered relatively recently as a metallic element, is a vital strategic resource. Due to its advantages, such as high strength, high melting point, corrosion resistance, and wear resistance, molybdenum finds extensive industrial applications. In China, molybdenum is classified as one of the six dominant mineral resources with relatively abundant reserves. The production sources of molybdenum primarily consist of three categories:

(1) Primary molybdenum from dedicated molybdenum mines;

(2) Co-produced or by-product molybdenum from copper mines;

(3) Molybdenum recovered from scrap catalysts containing molybdenum.

Among these, the first two categories account for the vast majority of molybdenum production. Notably, the production cost of co-produced molybdenum is comparatively lower than that of primary molybdenum.

Floatability Characteristics of Molybdenite

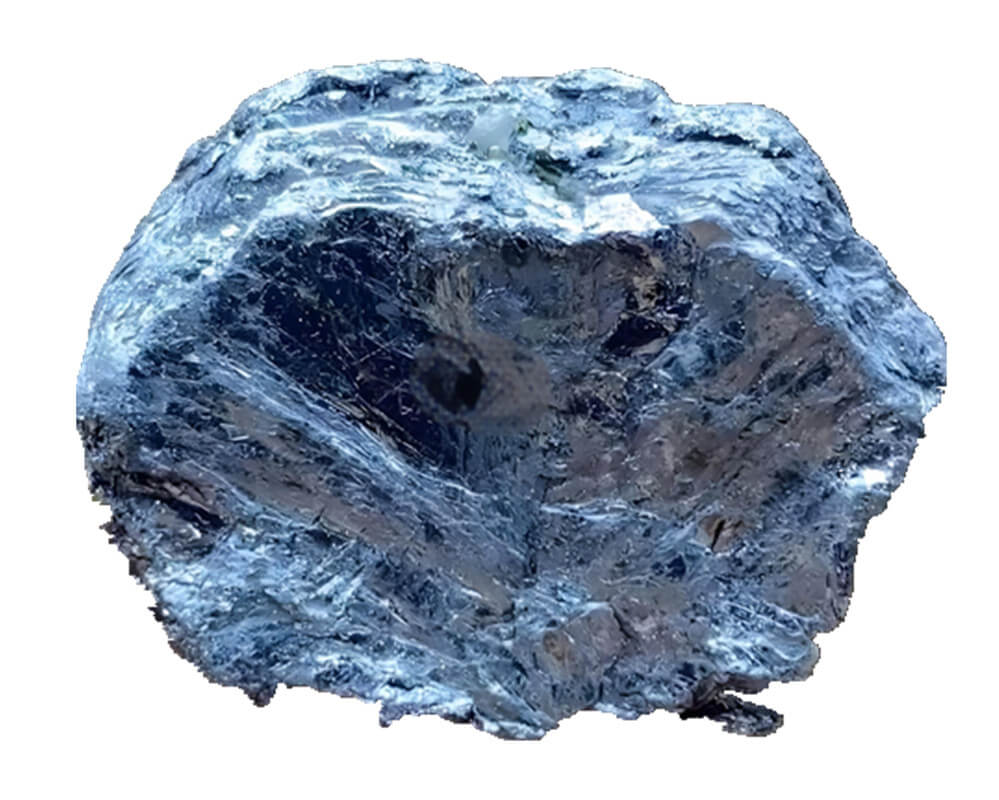

Among molybdenum-bearing minerals, molybdenite is the most widely distributed and possesses the highest industrial value. Currently, 99% of the world’s molybdenum production is derived from molybdenite. Molybdenite exhibits a typical hexagonal crystal system, with a coordination number of 6 for molybdenum atoms. Each molybdenum ion is surrounded by six sulfur ions arranged at the vertices of triangular prisms, forming a layered hexagonal or plate-like structure. The structure consists of S-Mo-S layers held together by weak van der Waals forces, resulting in exceptionally weak interlayer bonding. During mining, crushing, and grinding processes, the exposed non-polar, low-energy, and inert crystal surfaces along the cleaved S-Mo-S layers, referred to as “faces,” exhibit excellent hydrophobicity. Consequently, molybdenite demonstrates exceptional natural floatability. Based on this characteristic, flotation is predominantly employed as the primary beneficiation method for molybdenite recovery.

Molybdenum Ore Beneficiation Methods

The primary beneficiation method for molybdenum ore is flotation, targeting the recovery of molybdenite. Occasionally, chemical beneficiation processes are employed to further enhance molybdenum concentrate quality and remove impurities.

Molybdenum ore crushing generally employs a three-stage closed-circuit process to achieve a final product size of 12-15 mm. Grinding is typically performed using ball mills or a combination of rod and ball mills, with Henderson being the only operation utilizing a semi-autogenous grinding (SAG) process. Priority flotation is adopted, where rough flotation produces a molybdenum rough concentrate, while tailings from rougher and scavenger stages either discard or recover associated minerals. The molybdenum rough concentrate undergoes two to three stages of regrinding and four to five cleaning stages to obtain the final molybdenum concentrate.

Non-polar oils are generally used as collectors in molybdenum ore flotation, supplemented with frothers. In the United States and Canada, surfactants such as Syntex are employed as oil emulsifiers. Depending on ore characteristics, lime serves as a regulator, sodium silicate as a gangue depressant, and sometimes cyanides or sulfides are added to suppress other heavy metal minerals.

To ensure molybdenum concentrate quality, further separation is required for impurities such as copper, lead, and iron heavy metal minerals, calcium oxide, and carbonaceous materials present in the concentrate. Sodium sulfide or sodium hydrosulfide, cyanides, or ferrocyanides are typically used to control copper and iron, while dichromates or Nokes reagents are employed for lead depression. If impurity content still fails to meet quality standards with depressants alone, chemical beneficiation processes may be supplemented: secondary copper sulfides are leached with cyanides; chalcopyrite is leached with ferric chloride solution; and galena is leached with hydrochloric acid and ferric chloride solution, all capable of achieving standard levels.

Gangue minerals containing calcium oxide are prone to sliming; thus, overgrinding should be strictly avoided for ores containing such gangue. In practice, sodium silicate, sodium hexametaphosphate, or organic colloids are often used as gangue depressants or dispersants. Alternatively, activated carbon combined with CMC (carboxymethyl cellulose) can effectively suppress carbonate gangue. Final treatment may involve leaching with hydrochloric acid or hydrochloric acid plus ferric chloride solution.

For the separation of carbonaceous minerals, it is crucial to first identify whether the carbonaceous material belongs to the graphite, bitumen, or coal categories. These carbonaceous materials exhibit floatability similar to molybdenite but have lower densities, making gravity separation generally suitable for their removal. Sodium hexametaphosphate and CMC can be used to suppress carbon while floating molybdenite; alternatively, ferric chloride, sodium silicate, and sodium hexametaphosphate also effectively suppress carbonaceous materials; roasting to remove organic carbon is another viable approach. It should be noted that none of these carbon separation methods is entirely satisfactory at present, representing an unsolved challenge in the field.

High silica (SiO2) content in gangue often affects the molybdenum concentrate grade. Studies reveal that SiO2 content decreases with increasing molybdenum concentrate grade, showing a mutually consumptive trend. As long as molybdenum minerals achieve full liberation fineness, SiO2 content typically falls below standard levels. Alternatively, adsorbing oil reagents from molybdenum surfaces with activated carbon, followed by CMC to suppress silicate gangue, can also reduce SiO2 content to standard levels.

Beneficiation Methods for Single Molybdenum Ores

For most single molybdenum ores, the typical beneficiation process involves coarse grinding and roughing followed by regrinding and cleaning. The theoretical basis for coarse grinding and roughing lies in molybdenite’s excellent natural floatability—tests show that molybdenite middlings of 1/16-1/24 can float effectively in the presence of high-boiling-range (emulsified) hydrocarbon oils. Although molybdenite floats readily, its concentration in ores is extremely low, typically ranging from 0.01% to 0.45%, with ore grading above 0.2% considered rich. Simultaneously, molybdenum concentrate quality requirements are stringent, demanding molybdenum content above 45%-47%. Consequently, the enrichment ratio during molybdenite flotation exceeds 400, necessitating multiple (typically 4-10) cleaning stages.

Being relatively soft, molybdenite tends to slime during fine grinding, adversely affecting concentrate quality. Moreover, its excellent natural floatability allows even relatively coarse (up to 0.6mm) poor middlings to float efficiently with merely 1% exposed surface. Therefore, adopting a coarse grinding-roughing stage followed by regrinding of the rough concentrate (containing abundant middlings) to achieve complete liberation and multiple cleaning stages – a multi-stage regrinding, multi-stage cleaning process-proves optimal.

Beneficiation Methods for Copper-Molybdenum Ores

Copper-molybdenum ores represent a major source of molybdenum, accounting for 48% of global molybdenum production. Copper-molybdenum deposits where copper is primary and molybdenum secondary often occur as porphyry copper deposits. Due to their large reserves, these deposits serve as crucial current copper resources while simultaneously being significant molybdenum sources. Characterized by low-grade raw ore and fine dissemination size, with molybdenite’s layered structure exhibiting excellent natural floatability and close association with chalcopyrite and pyrite, recovering molybdenite from such deposits proves more challenging than from primary molybdenum ores, involving more complex flowsheets where molybdenum recovery is often constrained by copper recovery priorities.

Two principal methods exist for copper-molybdenum separation in such ores: preferential flotation and bulk flotation. The bulk flotation approach—obtaining a copper-molybdenum bulk concentrate first, then separating copper and molybdenum from it—is more commonly employed. While obtaining the bulk concentrate is relatively straightforward, given the excellent floatability of both copper sulfide minerals and molybdenite, subsequent separation of copper and molybdenum minerals presents significant challenges, usually requiring physical or physicochemical pretreatment before copper-molybdenum separation.

Conclusions

- Molybdenite exhibits excellent natural floatability, making flotation the predominant beneficiation method for its recovery.

- The exceptionally high enrichment ratio during molybdenite flotation necessitates multi-stage regrinding and multiple cleaning stages to obtain high-quality molybdenum concentrate from single molybdenum ores.

- For molybdenum recovery from copper-molybdenum ores, the typical approach involves separating molybdenum from bulk copper-molybdenum concentrate, with the key challenge being copper-molybdenum separation. Current copper-molybdenum separation methods include conventional flotation, nitrogen flotation, pulsating high-gradient magnetic separation, and passivation processes, with conventional flotation being predominant.