In mineral processing and metallurgy, comminution is one of the most energy-intensive stages, with ball mills dominating traditional grinding processes. However, driven by rising demands for energy savings and emission reductions, High-Pressure Grinding Rolls (HPGR) have emerged as a revolutionary alternative due to their superior efficiency and lower energy consumption. This article explores the technical advantages of HPGRs, compares them with conventional ball mills, and evaluates their practical potential in ore processing.

1. Core Advantages of HPGRs

Unlike ball mills, which rely on impact and abrasion, HPGRs operate on the principle of interparticle compression, delivering key benefits:

Higher Energy Efficiency

- 20%-50% lower energy consumption, particularly effective in fine grinding of hard ores (e.g., iron, copper).

- Higher energy utilization (only 30%-40% loss60%-70% in ball mills).

Better Particle Size Control

- Produces more uniform particle distributionswith micro-cracks, enhancing downstream leaching or beneficiation.

- Can replace multi-stage crushing/grinding circuits, simplifying flowsheets.

Economic & Environmental Benefits

- Reduced steel media consumption, lowering operational costs.

- Lower noise and dust emissions, aligning with green mining standards.

2. HPGR vs. Ball Mill: Key Comparisons

| Parameter | HPGR | Ball Mill |

| Grinding Mechanism | Compressive bed breakage | Impact + abrasion (steel balls) |

| Energy (kWh/t) | 3–6 (hard ores) | 10–25 (varies with hardness) |

| Particle Size | 80% below 2mm (adjustable) | Requires classification, prone to overgrinding |

| Maintenance Cost | Longer roller life (tungsten carbide liners) | Frequent ball/lining replacement |

| Best Application | Pre-grinding for hard-to-medium ores | Fine grinding (<100μm) |

3. Application Potential & Challenges

Key Opportunities

Metal Mining:

- Gold/Copper Ores: HPGR pretreatment can boost cyanide leach recovery (5%-10% increase).

- Iron Ore: Replaces SAG mills in crushing circuits, reducing costs per ton.

Non-Metallic Minerals: Cement raw materials & aggregates show significant energy savings.

Circular Economy: Efficient in e-waste and slag recycling.

Current Limitations

Higher Capital Cost: Initial investment 2-3x higher than ball mills (offset by long-term savings).

Material Adaptability:

- Sticky/moist ores accelerate roller wear.

- Requires air classification for optimal fineness.

Technical Barriers: Key components (e.g., hydraulic systems) still rely on imports in some regions.

4. High-Pressure Roller Mill Application Projects

Iron Ore Beneficiation Plant

A certain iron ore beneficiation plant has a capacity of processing 3.4 million tons of ore per year. After coarse crushing underground, the ore is hoisted to the surface system and then enters the beneficiation plant. The feed particle size is -300 mm, and the iron grade is 19.75%.

Original Beneficiation Plant Process

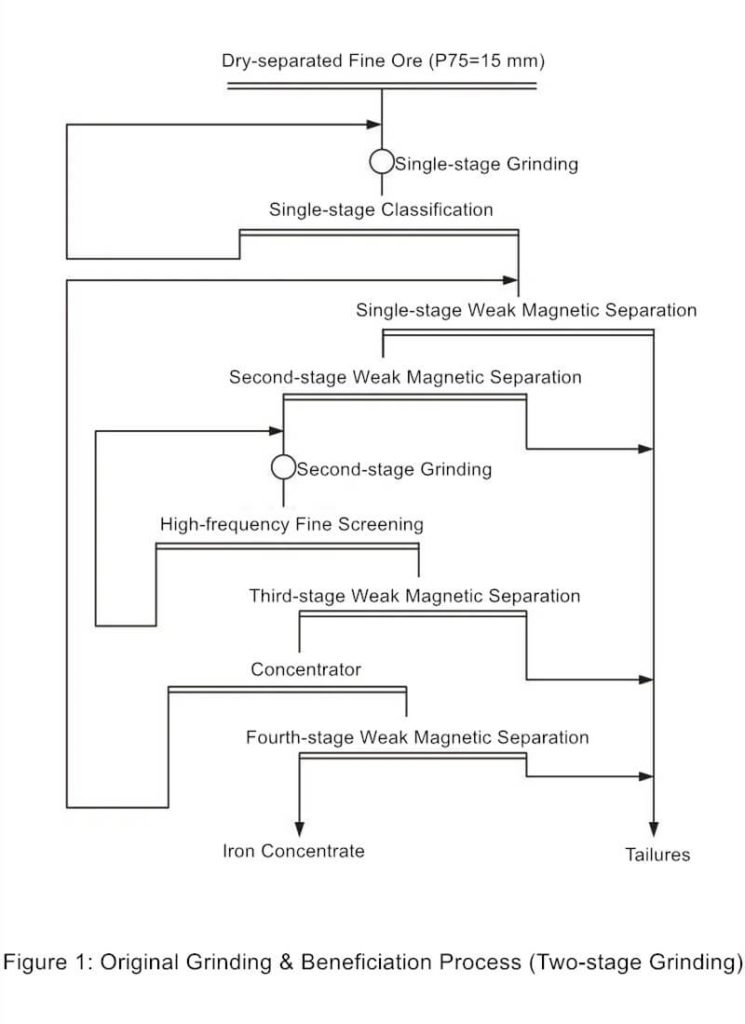

The beneficiation plant originally used a three-stage closed-circuit crushing process. Under this process, the product particle size of -15 mm accounted for more than 75%. To meet production and operation needs, several partial technical modifications have been made, but it still cannot meet the ore supply requirements for grinding and beneficiation operations. The grinding process adopts a staged grinding and beneficiation + two-stage weak magnetic separation + washing and filtration process(The specific process flow is shown in Figure 1). The average proportion of -0.074 mm particle size in the overflow discharge from the first-stage ball mill and classifier is 21.34%, ultimately producing iron concentrate with an iron grade of 66.50% and a fineness of 65.00%.

High-Pressure Roller Mill Design

To improve mineral processing efficiency and reduce production costs, the mineral processing plant, referencing the successful experience of high-pressure roller mills in other large-scale plants in the surrounding area, and after comparing and demonstrating multiple options, ultimately adopted a high-pressure roller mill to replace the single-stage grinding process.

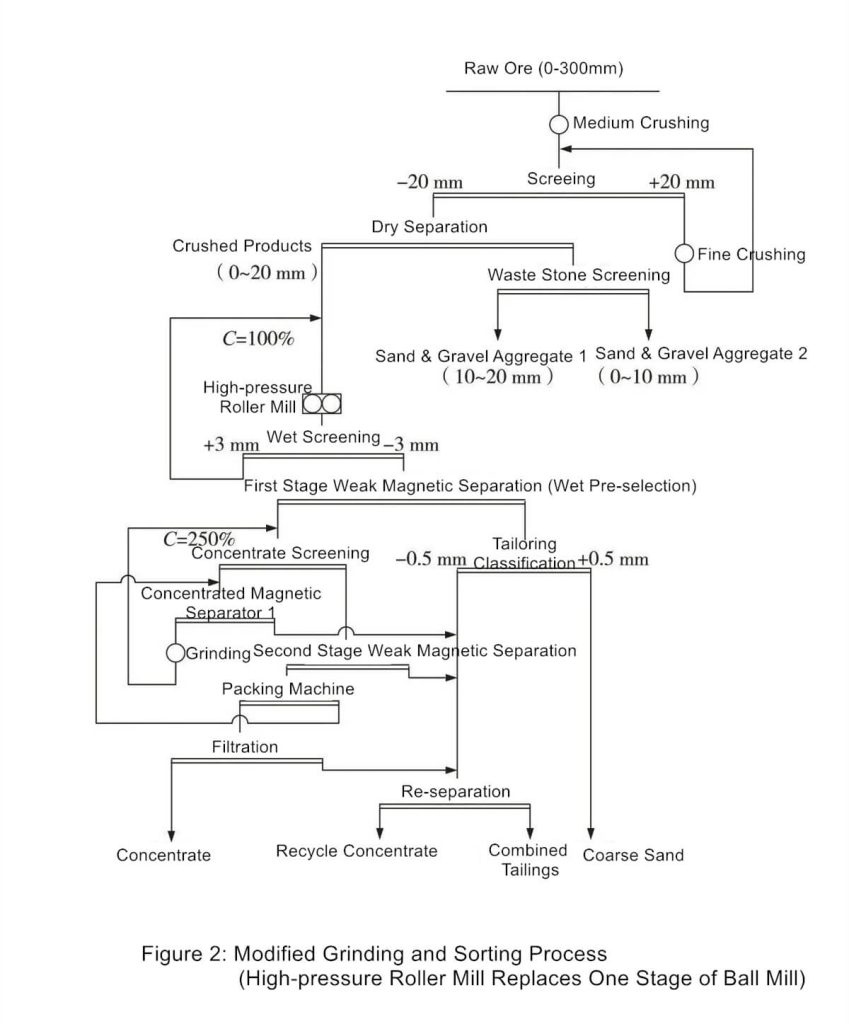

The process design employs a two-stage closed-circuit crushing + high-pressure roller mill + ball mill process flow. The raw ore is coarsely crushed to 300–0 mm and then enters the fine crushing and closed-circuit screening system in the mineral processing stage, where it is further crushed to 20–0 mm and then subjected to dry separation and tailings disposal. The concentrate enters the high-pressure roller mill closed-circuit screening system, producing ore of 3–0 mm, which is then fed into a large-particle wet pre-magnetic separator. The pre-magnetically separated concentrate is then fed into the grinding system. Compared to the original mineral processing flow, the new process eliminates one grinding stage. This improvement aims to achieve a more efficient crushing effect through the high-pressure roller mill, thereby improving overall mineral processing efficiency and reducing energy consumption. The specific process flow is shown in Figure 2.

Efficiency of High-Pressure Roller Milling

To determine the feasibility of replacing a single-stage ball mill with high-pressure roller milling, a field industrial test was conducted. By comparing and analyzing the particle size distribution of products at different process stages, the applicability and advantages of high-pressure roller milling technology in actual production were evaluated. Specific data obtained from the experiment are shown in Table 1.

| No. | Roller mill feed -3mm percentage (%) | Roller mill discharge -3mm percentage (%) | Wet screen discharge –0.074mm percentage (%) |

| 1 | 26.25 | 53.24 | 19.91 |

| 2 | 29.54 | 54.92 | 25.07 |

| 3 | 32.15 | 52.81 | 23.18 |

| Average | 29.31 | 53.66 | 22.72 |

Table 1: Field Test Data

As can be seen from Table 1, the average proportion of -3 mm particles in the roller mill feed was 29.31%. Before entering the roller mill stage, the ore had already undergone a coarse crushing process, but a large amount of coarse particles remained. Coarse ore requires greater stress during roller milling to achieve effective crushing, which may lead to increased energy consumption and wear of the roller mill. Therefore, optimizing the coarse and medium crushing processes to reduce the proportion of coarse ore entering the roller mill is an important direction for improving overall grinding efficiency and reducing energy consumption.

The average proportion of -3 mm particles in the roller mill discharge significantly increased to 53.66%, indicating that the high-pressure roller mill, by applying high pressure, allows the ore to be more fully squeezed and crushed between the rollers, effectively increasing the proportion of fine particles. High-pressure roller mills, by adjusting roller pressure and roller spacing, can adapt to ores with different physical properties, achieving more uniform and efficient crushing. Furthermore, the fine-grained products produced during the discharge process of the high-pressure roller mill help reduce the load on subsequent ball mills, further improving the overall grinding process efficiency.

The average proportion of -0.074 mm particles in the wet screen discharge is 22.72%, indicating that the fineness of the ore has been improved after high-pressure roller milling, but there is still room for improvement. The particle size distribution of the wet screen discharge reflects the fine grinding effect of the high-pressure roller mill and also points out potential problems in subsequent processes. The proportion of -0.074 mm particles in the wet screen discharge is lower than expected, indicating that the crushing effect of the roller mill has not yet reached its optimal state. This may be due to the roller mill’s operating parameters (such as roller pressure and roller spacing) not being optimally adjusted, or because the physical properties of the ore (such as hardness and toughness) are not perfectly matched with the roller mill’s operating conditions.

Conclusion

With their advantages in energy savings, particle size control, and environmental compliance, HPGRs demonstrate strong potential to replace conventional ball mills—particularly in hard ore pre-grinding. Despite higher upfront costs and material limitations, ongoing technology advancements and scaling adoption could solidify HPGRs as a green cornerstone of mineral processing. Future breakthroughs in smart controls and wear-resistant materials may further revolutionize grinding efficiency standards.