Phosphate rock, a critical non-renewable resource rich in phosphorus and primarily composed of calcium phosphate minerals like apatite, is essential for agriculture, chemicals, and advanced materials.

China, which holds the world’s second-largest phosphate reserves, features diverse deposit types—igneous apatite, sedimentary phosphorite, and metamorphic phosphorite—each presenting unique mineralogical and processing challenges. Sedimentary phosphorite dominates production, accounting for 70% of reserves; however, the fine particle size, carbonate impurities, and declining ore grades necessitate innovative beneficiation approaches. To address these challenges, Chinese researchers are pioneering efficient extraction methods, utilizing techniques such as reverse flotation, calcination, and hybrid separation, while also maximizing byproduct recovery of valuable materials like rare earths and iodine. Understanding these ores and their treatment is vital for sustaining China’s strategic position in global phosphate markets, where extractable phosphorus is primarily used to produce phosphoric acid and phosphates for fertilizers.

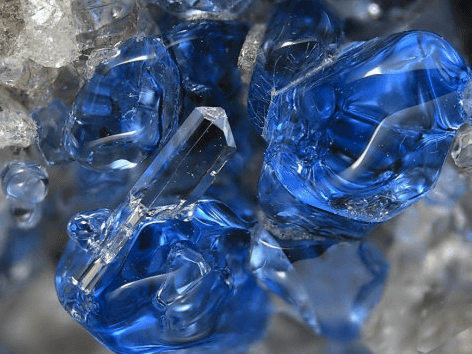

Apatite

Apatite is an important mineral with the chemical formula of Ca5(PO4)3(F,Cl,OH). Its main chemical component is calcium phosphate, which usually contains elements such as calcium, phosphorus, fluorine, chlorine, and hydrogen. Apatite is a phosphate mineral that is widely found in nature. Apatite crystals are hexagonal columns, and aggregates are granular, dense blocks, earthy, and nodular. The color of apatite varies. The one without impurities is transparent. Common colors are light green, yellow-green, brown-red, and light purple. On the Mohs hardness scale, the hardness of apatite is approximately 5, indicating a medium hardness mineral. The specific gravity is 3.18~3.21g/cm3, and it emits green light after heating.

Apatite Variant

The most common minerals in nature that can form mineral deposits are the following five categories: fluoroapatite, chlorapatite, carbonapatite, hydroxyapatite, and carbonapatite.

- Fluorapatite

The chemical formula is Ca5(PO4)3F, and it is a type of apatite containing fluoride ions. Fluorapatite is common in some igneous and metamorphic rocks and is also an important component of teeth and bones.

- Chlorapatite

The chemical formula is Ca5(PO4)3Cl, and it is a type of apatite containing chloride ions. This mineral is relatively rare and typically occurs in specific mineral deposits and metamorphic rocks. - Carbonapatite

A type of apatite containing carbonate ions in the form of Ca5(PO4)3(CO3). It is an important component in biomineralization and is commonly found in some biologically generated minerals, such as corals and the skeletons of some marine organisms. - Hydroxyapatite

The chemical formula is Ca5(PO4)3(OH). It is the most common type of apatite in nature and the main component of bones and teeth. Hydroxyapatite has important applications in biomedicine and dental materials. - Carbonofluorapatite

A type of apatite containing fluorine and carbonate, usually formed under some special environments. Its properties are between fluorapatite and carbonapatite, with dual characteristics.

There are many associated minerals in natural phosphate ore, also known as impurity minerals or gangue, mainly silicon minerals and carbonate minerals. The former is mainly quartz or cristobalite (or its hydrates such as flint or opal), clay minerals, or other silicate minerals such as feldspar and mica. The latter is mainly limestone and dolomite.

China Phosphate Rock Ore

There are three types of phosphate rock in China: igneous apatite deposit, sedimentary phosphorite, and metamorphic phosphorite.

1. Igneous Apatite Deposit

Features

- Formation environment: This type of phosphate rock is mainly formed by volcanic activity, accompanied by the condensation and crystal separation of igneous rocks.

- Mineral composition: It mainly contains apatite, and may also be accompanied by other minerals such as pyroxene, plagioclase, etc.

- Distribution: This type of phosphate rock is relatively rare and is mainly distributed in some high-temperature igneous rock areas.

Ore dressing methods

- Crushing and grinding: The ore particle size is reduced by mechanical crushing and grinding.

- Flotation: The difference in physical and chemical properties between apatite and associated minerals is used for flotation separation, and a regulator is usually added to improve the separation efficiency.

- Gravity separation: Sometimes suitable for the separation of specific minerals.

2. Sedimentary Phosphorite(China’s core phosphate rock types)

Features

- Formation environment: This type of phosphate rock is formed by biological and chemical sedimentation processes, usually related to marine sedimentary environments.

- Mineral composition: It is mainly composed of phosphorite (the sedimentary form of apatite), and usually contains other minerals such as quartz, calcite, etc.

- Distribution: Sedimentary rock type phosphorite is the main type in countries around the world. The reserves of this type of ore in my country account for 70% of the total reserves, mainly distributed in central, southern, and southwestern China. Yunnan, Guizhou, Sichuan, Hubei, and Hunan provinces account for 78% of the reserves of this type, which can be said to be the hometown of phosphorite.

Ore dressing methods

- Crushing and grinding: The ore also needs to be crushed and ground.

- Flotation: This is the main beneficiation method for sedimentary rock-type phosphorite. Foam flotation technology can be used to separate phosphorite from associated minerals.

- Gravity separation: Gravity separation is carried out according to the density difference of minerals, usually used for the pretreatment of raw ore.

Key challenges

① Fine embedding (-320 mesh accounts for 80-90%) leads to mud interference.

② Lattice replacement (CO₃²⁻→PO₄³⁻) reduces floatability.

③ Calcium-silicon symbiosis makes separation difficult.

Sorting technologies

(1) Siliceous

- Conventional positive flotation: Na2CO3 slurry adjustment + water glass inhibition of silica + oxidized paraffin soap capture.

- Concentrate P2O5 recovery rate>85%, but with high energy consumption.

(2) Calcareous

- Reverse flotation scheme: H2SO4 adjusts pH to 4-5 + phosphoric acid inhibits apatite + flotation of calcium minerals.

- Roasting-digestion method (roasting at 1000℃):

→ P2O5 grade increased to 38%, recovery rate 97%.

→ Synchronous recovery of iodine (flue gas treatment)

(3) Silicon-calcium mixed type (Most Complex)

- Reverse-forward flotation combination: first float calcium (H2SO4 medium) → then float apatite (new inhibitor S-808/F103).

- Reinforcement-flotation combination: cyclone pre-discarding → reduce flotation volume by 30%.

- S-BOS innovative process: roasting → digestion → CO2 mineralization → flotation, achieving low-temperature (9°C) separation.

3. Metamorphic Phosphorite

Features

- Formation environment: This type of phosphate ore is formed by sedimentary rocks under metamorphism, usually with high temperature and pressure.

- Mineral composition: The main component is metamorphic apatite, which may be accompanied by quartz, mica, pyroxene, etc.

- Distribution: It is more common in some specific geological environments.

Ore dressing methods

- Crushing and grinding: Preliminary crushing and grinding are also required.

- Flotation: Separation is mainly carried out by flotation, but due to the change of ore characteristics caused by metamorphism, the dosage and type of flotation reagents may need to be adjusted.

- Heat treatment: Sometimes heat treatment can be used to remove certain impurities, improve the recovery rate of phosphorus, and improve the selectivity of the ore.

Apatite phosphate ore is an easy-to-select ore. However, its grade is low, usually P2O5 <10%. If phosphorus is recovered alone, it is not economically viable, and comprehensive utilization must be carried out. This type of phosphate ore contains a variety of useful minerals that can be comprehensively utilized, such as iron, titanium, vanadium, platinum group, iodine, garnet, vermiculite, biotite, diopside, etc. As long as comprehensive utilization is carried out, the economic benefits of this type of ore will be considerable.

Conclusion

As global demand for phosphate grows, China’s ability to optimize its complex, lower-grade resources becomes ever more crucial. Advances in mineral processing, waste reduction, and co-product recovery are reshaping the industry, turning challenging ores into economically viable assets. The next frontier lies in AI-driven sorting, sustainable reagents, and integrated resource utilization, ensuring both profitability and environmental compliance. Whether for fertilizers, lithium-ion batteries, or industrial chemicals, China’s phosphates will remain indispensable. By investing in R&D and adopting cleaner extraction technologies, China can secure its phosphate supply chain while minimizing ecological impacts—a balance vital for future food and energy security.