The world of mineral processing has many techniques and tools, but hydrocyclones stand out. Have you ever wondered how they work or what they can do for your operation? Let’s dive into the mystery behind these fascinating devices.

Hydrocyclones are vital tools in ore dressing, primarily separating solids from liquids by using centrifugal force. They are highly efficient in classifying fine particles and can significantly enhance your mineral processing operations. Understanding their operation and benefits can help you optimize your processes and improve productivity.

Hydrocyclones can be confusing at first glance. Understanding how they function, their types, and their benefits can help you make informed decisions about your mining operations. By shedding light on these critical components, I hope to empower you to enhance the efficiency of your mineral processing.

What is a Hydrocyclone?

The hydrocyclone is a common piece of separation and classification equipment, which typically utilizes the principle of centrifugal sedimentation. When the two-phase mixed liquid to be separated enters the hydrocyclone tangentially from the periphery of the hydrocyclone at a certain pressure, a strong three-dimensional, elliptical, strong rotational shear turbulent motion is generated. Due to the difference in particle size between coarse particles and fine particles, they are subjected to different centrifugal forces, centripetal buoyancy, fluid drag, etc. Under the action of centrifugal sedimentation, most of the coarse particles are discharged through the bottom flow port of the hydrocyclone, while most of the fine particles are discharged from the overflow pipe, thereby achieving the purpose of separation and classification.

Advantages and Disadvantages of Hydrocyclones

Hydrocyclones bring numerous benefits, but they also come with challenges. Understanding both sides is critical for anyone in the mining industry.

Advantages of the cyclone separator

Compared with other solid control equipment, the cyclone separator has the following advantages:

- Compact design, simple structure, low cost, and no moving parts.

- High processing capacity and wide separation range.

- Simple adjustment and operation, easy to maintain.

- Strong separation capability; in certain cases, finer overflow and higher separation efficiency can be achieved. The separation efficiency is generally 60%, and in some cases can reach 80%-90%.

Disadvantages of cyclones

Compared with other solid control equipment, cyclones have the following disadvantages:

- High power consumption.

- When the viscosity, solid phase concentration, and particle size distribution of the feed slurry change, the separation particle size and separation efficiency of the cyclone also change accordingly.

- The operating conditions of the sand pump significantly affect the performance of the cyclone.

- It cannot perform ultra-fine separation or handle flocculated materials.

- Rapid wear, especially when particle size is large, drill cuttings are hard, and feed slurry concentration is high, leading to wear at the feed port of the cylinder, the lower half of the cone, and the sand discharge port.

What Are The Main Types of Hydrocyclones?

Hydrocyclones can be categorized based on construction and function. According to construction, there are single-stage hydrocyclones and double-stage hydrocyclones. Based on their function, they can be classified into several types: classification hydrocyclones, dewatering hydrocyclones, desanding hydrocyclones, sludge removal hydrocyclones, concentration hydrocyclones, and tailing dry discharge hydrocyclones.

1. Single-stage Hydrocyclones

Single-stage hydrocyclones are widely used in metal and non-metal mineral processing plants with a daily processing capacity of over 500 tons. They operate in closed-circuit grinding alongside a single-stage ball mill. These hydrocyclones can be arranged either individually or in groups based on different processing capacities. At higher feed concentrations, they exhibit high classification efficiency and finer overflow particle sizes, ensuring uniform overflow products. Their classification efficiency is generally 5-10% higher than that of traditional spiral classifiers, which improves the utilization coefficient of the mill.

- Large Cone Angle Hydrocyclones

These hydrocyclones feature a larger cone angle, up to 180 degrees (also known as flat-bottom hydrocyclones). They are suitable for high-density materials and applications requiring an overflow particle size of 60% under -200 mesh, particularly effective in the first stage of grinding for iron ore. Their design provides uniform overflow particle size and minimizes over-grinding, with adjustable underflow yield without impacting normal operation. Compared to conventional hydrocyclones, they can increase processing capacity by 10-25%. - High Fineness Classification Hydrocyclones

Ideal for first-stage grinding where the target fineness is over 80% under -200 mesh. Traditional hydrocyclones struggle to achieve desired classification sizes while maintaining efficiency, leading to increased sand return and reduced feed rate. High fineness classification hydrocyclones are structurally modified to minimize coarse overflow and fine underflow, achieving high overflow fineness while retaining classification efficiency.

2. Double-stage Hydrocyclones

Double-stage hydrocyclones are commonly used in metal and non-metal minerals for second-stage checking and control classification. They come in specifications ranging from 75mm to 660mm, accommodating various processing volumes and different grinding fineness requirements. The unique design of these hydrocyclones allows for an adjustable overflow particle size from 75% to 95% under -200 mesh.

3. Dewatering Hydrocyclones

Dewatering hydrocyclones are primarily used for dewatering various mineral slurries. Depending on the material characteristics and installation environments, different structural designs are adopted. They offer reduced pressure, large processing capacity, and high dewatering efficiency. For instance, in tailings re-selection slurry dewatering with 5-12% feed concentration and 75% under -200 mesh, the average overflow concentration is kept below 1.5%, effectively achieving dewatering while preventing loss of valuable minerals. In silica sand dewatering, overflow concentration can drop below 0.5%, with nearly only unqualified fine mud discharged, thereby achieving dual purposes of dewatering and desanding.

4. Desanding Hydrocyclones

High-efficiency desanding hydrocyclones are mainly used for desanding metal and non-metal mineral slurries. These hydrocyclones capitalize on successful international designs and, through years of practice, have optimized the proportions and compatibility of their major components. They boast high desanding efficiency, minimal loss of valuable minerals, reduced user costs, and enhanced production efficiency.

5. Sludge Removal Hydrocyclones

These hydrocyclones are applied in processes such as flue gas desulfurization in power plants, lime slurry preparation, crude oil sludge removal, drinking water filtration, and wastewater treatment. They effectively eliminate coarse sand and metal particles from slurries, featuring high sludge removal efficiency and minimal loss of useful slurry.

6. Concentration Hydrocyclones

High-efficiency concentration hydrocyclones are typically used in conjunction with thickeners and filters for mineral concentration before filtration, grinding and flotation, cyanidation of gold-bearing slurries, and high-concentration tailings transport. After concentration and dewatering in the hydrocyclones, the increased underflow concentration enhances the efficiency of dewatering screens, and reduced overflow concentration alleviates the load on thickeners. Their unique design is widely applied across various mineral processing plants, maintaining underflow concentrations above 70% and yields over 75% even with feed concentrations around 8%.

How to Operate Hydrocyclones?

Operating hydrocyclones may seem complicated, but it does not have to be. To get started, you need to follow a few simple steps.

First, ensure the hydrocyclone is correctly installed and calibrated. Follow the manufacturer’s guidelines for slurry feed volume and pressure. Once set up, monitor the cyclone’s performance regularly to make sure it is operating efficiently. Adjust the feed rate and pressure to meet specific requirements. Fine-tuning these parameters leads to improved results.

Production Cases of Cyclones

Practical examples of hydrocyclones in action illuminate their effectiveness. For example, I witnessed their use in a copper mining operation where the plant needed to enhance recovery rates.

Hydrocyclones in Nigeria 120TPD Lithium Processing Plant

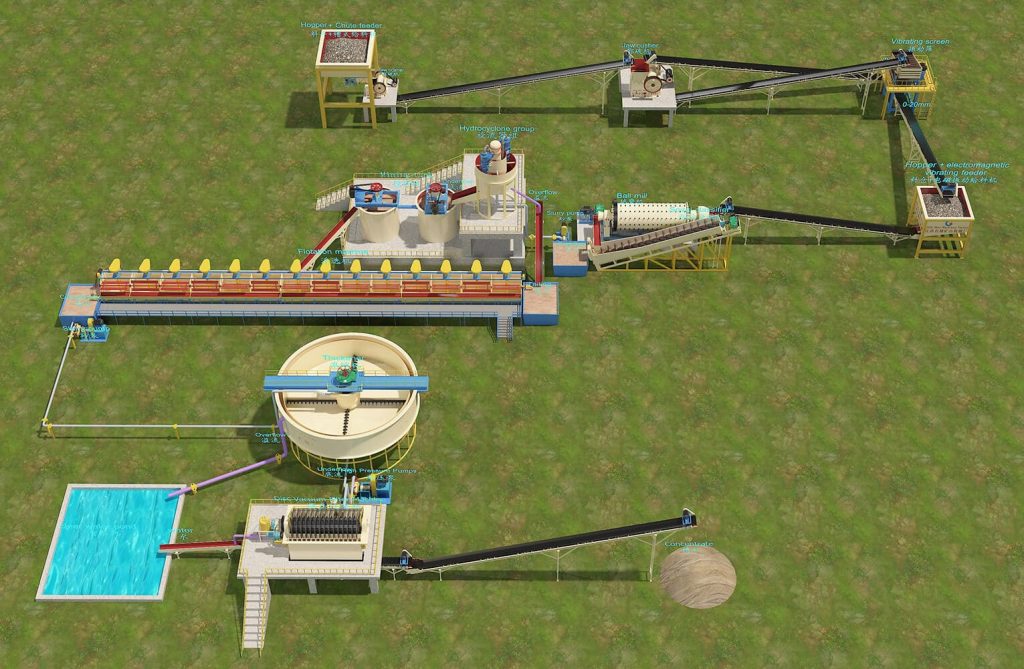

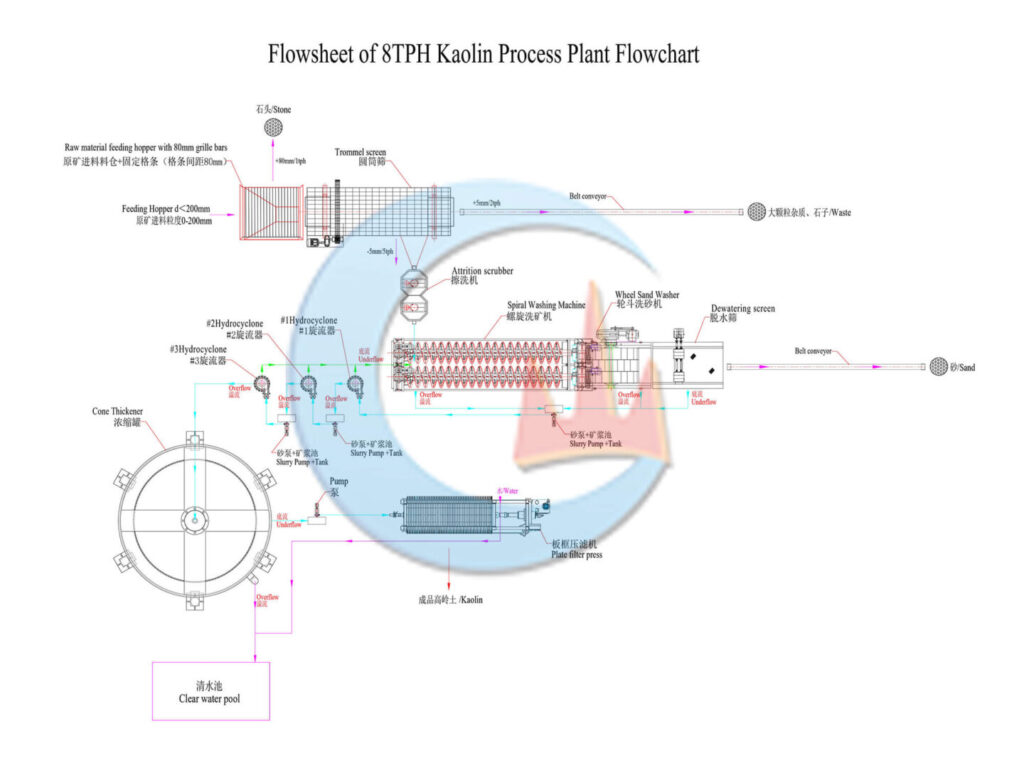

Hydrocyclones in Pakistan 10TPH Kaolin Process Plant

They incorporated hydrocyclones into their processing line, leading to a notable improvement in particle sizing and overall ore recovery. Following this adaptation, production efficiency increased significantly, and costs decreased. Observing these real-world applications reinforces the value that hydrocyclones can bring to any mining operation.

Conclusion

Hydrocyclones are indispensable in the world of mineral processing. They offer remarkable efficiency in separating particles, proving crucial in optimizing mining operations. Understanding how to operate them, along with knowing their pros and cons, can guide you in implementing them effectively in your own processes. Embracing these tools can lead to increased productivity and reduced costs in your mining endeavors.