Grinding systems are the backbone of mineral processing plants. But inefficient grinding can drain energy and reduce productivity. One key parameter for optimization is “circulating load.”

Circulating load refers to the amount of coarse material returned to the grinding mill for reprocessing in a closed-circuit system. Optimizing this load improves grinding efficiency, reduces energy waste, and ensures consistent product fineness.

If circulating load is too high or too low, it can hurt grinding performance. Let’s break down what it is, why it matters, and how to optimize it effectively.

Table of Contents

What is a Closed-Circuit Grinding?

What is Circulating Load in Closed-Circuit Grinding?

Ever wondered why some grinding systems reroute partially ground material back into the mill? Closed-circuit grinding solves a major efficiency problem.

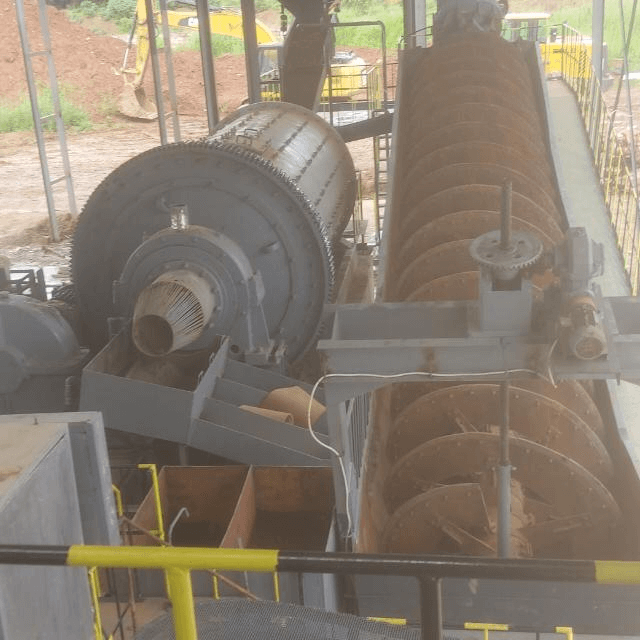

Closed-circuit grinding uses a classifier (like a hydrocyclone or screen) to separate fine product from coarse material, which is sent back to the mill for further grinding. This ensures consistent particle size while improving throughput.

Key Components & Their Role

A typical closed-circuit system includes:

| Component | Function |

| Grinding mill | Reduces ore size |

| Classifier | Separates fine and coarse particles |

| Return system (pumps, conveyors) | Recirculates coarse material |

The classifier determines the split between product (fines) and recirculated material (coarse). Overgrinding increases energy costs, while undergrinding means wasted mill capacity. Optimizing circulating load balances these risks.

In a closed-circuit grinding system, the slurry discharged from the grinding mill does not directly enter the next process but is first sent to classification equipment (such as hydrocyclones, spiral classifiers, etc.) for classification. The classifier separates the slurry into two parts: one part consists of fine-grained products that have reached the required particle size, referred to as “overflow,” which are output as qualified products; the other part consists of coarse-grained products that are still too coarse and require further grinding, referred to as ‘tailings’ or “returned slurry.” This material is returned to the grinding mill, mixed with newly fed raw ore, and ground again. Why does some material go back to the mill instead of exiting as product? The answer lies in efficiency.

Circulating load is the ratio of returned coarse material to fresh feed entering the mill, expressed as a percentage. A 200% circulating load means that for every ton of fresh feed, two tons of coarse material are returned.

Common Circulating Load Ranges

The ideal load varies by material and mill type:

| Mill Type | Typical Load (%) | Remarks |

| Ball mills | 100–350% | Depends on classification efficiency |

| SAG mills | 5–20% | Lower due to autogenous grinding |

The magnitude of the circulating load directly reflects the circulation state of the material inside the mill and the classification efficiency of the classifier. Its numerical value and fluctuations are directly related to a series of key production indicators, including the mill’s processing capacity, grinding efficiency, product particle size characteristics, and energy consumption. If the circulating load is too low, the mill underworks, wasting capacity; The circulating load is too high, overloading increases energy use and wear.

Why Care About Circulating Load?

Ever faced inconsistent grind size or spiking energy bills? Circulating load affects both.

A stable and appropriate circulating load is a sign of efficient operation in a closed-circuit grinding system. Both excessively high or low circulating loads can have adverse effects on production.

Low circulating load: This typically indicates poor classification efficiency, with a large amount of qualified fine-grained material failing to be promptly discharged from the overflow and instead being incorrectly returned to the mill. This results in prolonged residence time of the material within the mill, leading to severe “over-grinding.” Over-grinding not only wastes a significant amount of electrical energy and reduces the mill’s processing capacity but may also cause useful minerals to become muddy, posing a risk of reduced recovery rates in subsequent flotation and magnetic separation operations.

Excessively high circulating load: This means that a large amount of material circulates rapidly between the mill and classifier. While this can significantly reduce the residence time of material within the mill, effectively avoiding over-grinding and promoting more uniform product particle size, However, when the circulating load exceeds the mill’s maximum throughput capacity, it triggers the “bloating” phenomenon, causing a sharp decline in grinding efficiency and resulting in “coarse particle runaway,” where a large amount of unqualified coarse particles mix into the overflow product, severely affecting the final concentrate quality.

Therefore, controlling the circulating load within an optimal range is key to achieving “more crushing, less grinding,” energy conservation, and improving mill production quality. Practice has shown that for most mineral processing plants, controlling the circulating load between 300% and 500% typically yields good results, meaning the return sand volume is 3 to 5 times the original feed volume. However, the optimal value must be determined through testing and production practice based on ore properties, equipment performance, and process requirements.

How is Circulating Load Calculated?

To optimize the circulating load, it is first necessary to accurately measure and calculate it. In mineral processing production practice, the solid material balance method (sieve analysis method) and the slurry concentration method are mainly used.

1. Solid Material Balance Method (Screening Analysis Method)

This method is based on the principle of material balance and is the most accurate and reliable method, commonly used for process calibration and precise calculations. Its principle is: the mass of a specific particle size in the feed material of a classifier equals the sum of the mass of that particle size in the overflow and return sand.

Calculation formula: C = (α – γ) / (β – α) * 100%

Where:

- C: Circulation load rate (%)

- α: The content (%) of a specified particle size (typically the classification particle size or a coarser particle size) in the feed slurry of the classifier (i.e., the mill discharge).

- β: The percentage of the same specified particle size in the classifier return sand slurry.

- γ: The percentage of the same specified particle size in the classifier overflow slurry.

2. Slurry Concentration Method

Due to the cumbersome and time-consuming nature of the sieve analysis method, the slurry concentration method, which is faster and more convenient, is commonly used in daily production monitoring. This method is based on the balance of solids and water in each material flow.

C = (δgrind – δoverflow) / (δreturn – δgrind)

Where δgrind, δoverflow, and δreturn represent the solid material percentage concentrations of the mill feed, classifier overflow, and return sand, respectively.

How Can We Regulate Circulating Load?

Is your grinding circuit running inefficiently? Adjusting classifier operation or mill feed can help.

Key control methods include adjusting classifier speed, feed rate, or water addition. For hydrocyclones, apex size and pressure directly impact recirculation rates.

Control Strategies

| Method | Effect |

| Classifier speed | Faster = finer cut, lower load |

| Feed density | Thicker slurry = higher load |

| Apex adjustment (hydrocyclones) | Wider = more coarse return |

Regular sampling ensures the load stays within an optimal range.

How to Optimize Circulating Load?

Want to maximize grinding efficiency? Balancing feed size, classifier settings, and mill parameters is key.

Optimization involves testing different circulating loads, measuring energy use and grind size, then selecting the most cost-effective range (usually 200–250% for ball mills).

Steps to Optimize

- Benchmark current performance: Measure energy use, product size, load %.

- Adjust classifier: Test different settings to find the best cut point.

- Monitor changes:Track power draw, throughput, and product quality.

- Optimize feed size:Crushing ore finer reduces circulating load.

Benefits of Optimization

- Lower energy costs (up to 20% savings).

- Extended equipment life (reduced wear).

- Stable product quality (consistent particle size).

Conclusion

Circulating load is a critical parameter in closed-circuit grinding. It balances efficiency, energy use, and product quality. Calculating and optimizing it involves adjusting classifiers, monitoring feed rates, and testing mill performance. Keeping the load within the ideal range (often 200–250%) ensures cost-effective, high-quality grinding operations.