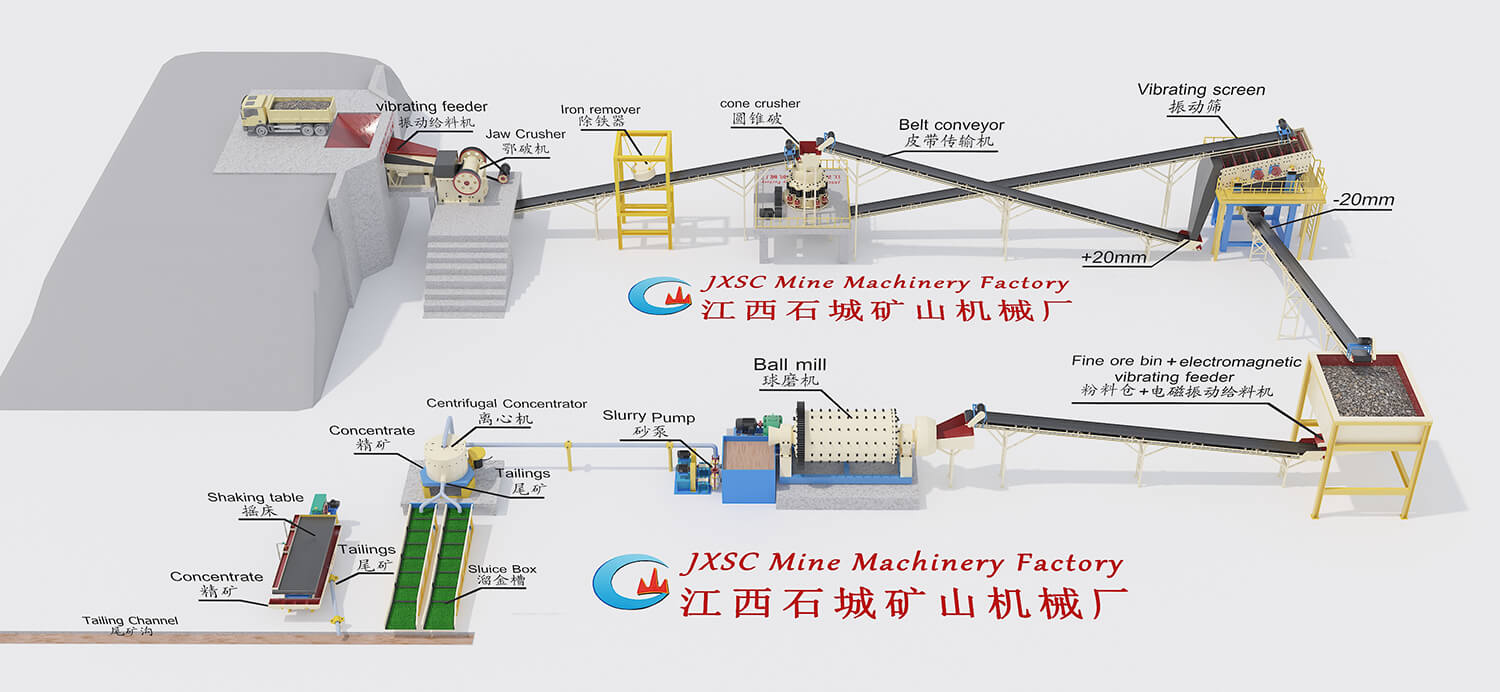

JXSC has provided a successful 5TPH alluvial tantalum & niobium process plant in Côte d’Ivoire. We designed the processing plant flowchart and plant layout drawing according to the client’s requirements. We provided a complete set of plant machines to the mine site.

EPCS

Engineering, Procurement & Construction Services

Case Study: Alluvial Tantalum & Niobium Process Plant Project

Project Overview

Minerals

Alluvial Tantalum & Niobium

Capacity

5 TPH

Feed Size

≤40 mm

Location

Côte d’Ivoire

Project Process

Solutions & Process

Our company successfully delivered a complete 5TPH alluvial tantalum & niobium processing plant in Côte d’Ivoire for a client who needed to validate the feasibility of their clay-rich deposit before full-scale production. The ore presented unique challenges – containing large waste rocks (40mm+), valuable minerals concentrated in the fine 0-2mm fraction, and problematic sticky clay that required special washing solutions. The project required innovative approaches to efficiently remove waste material, maximize recovery of ultra-fine concentrate, and create a compact system designed for future scalability to commercial production levels.

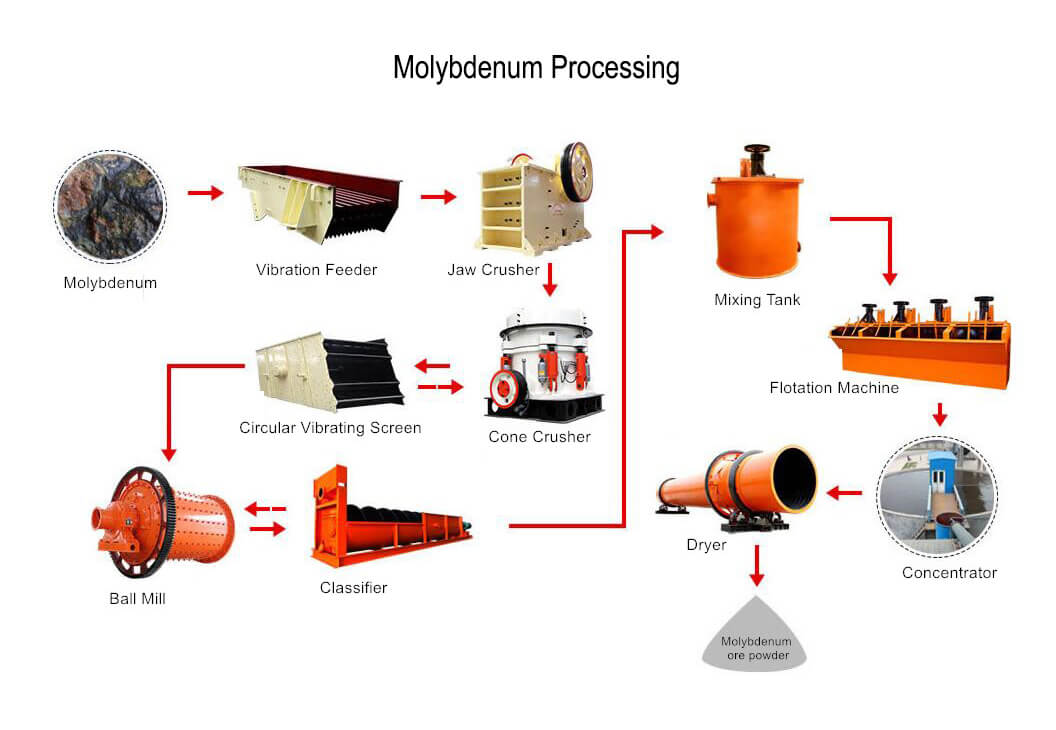

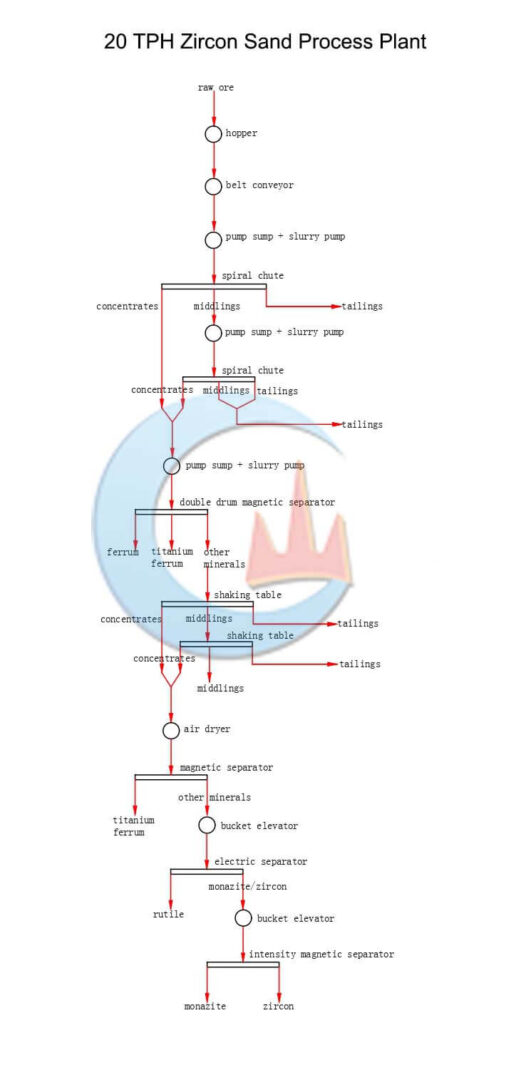

Process Flowchart

Customized Solution

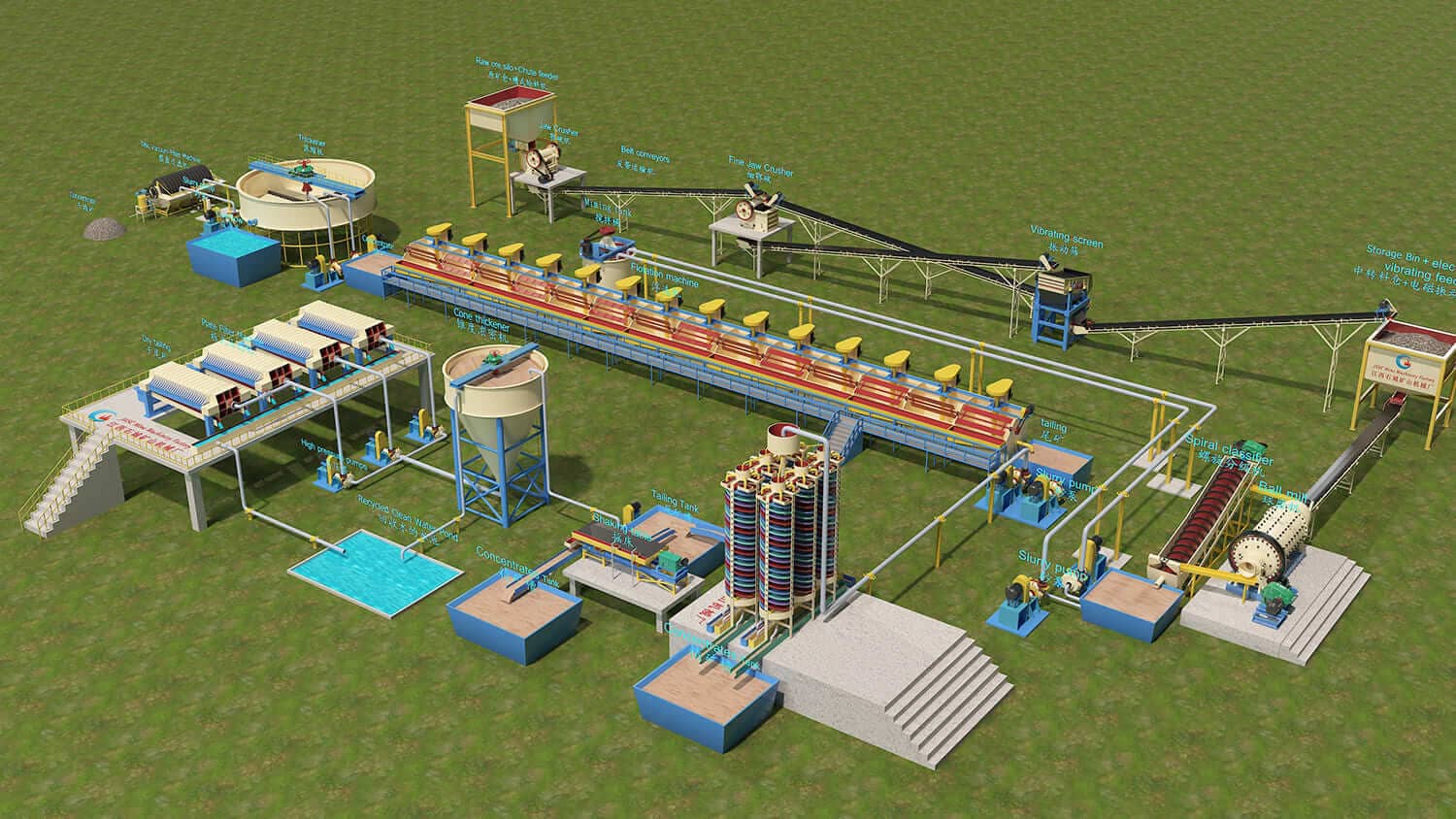

JXSC designed a multi-stage “Washing-Gravity-Magnetic” process tailored for sticky alluvial deposits:

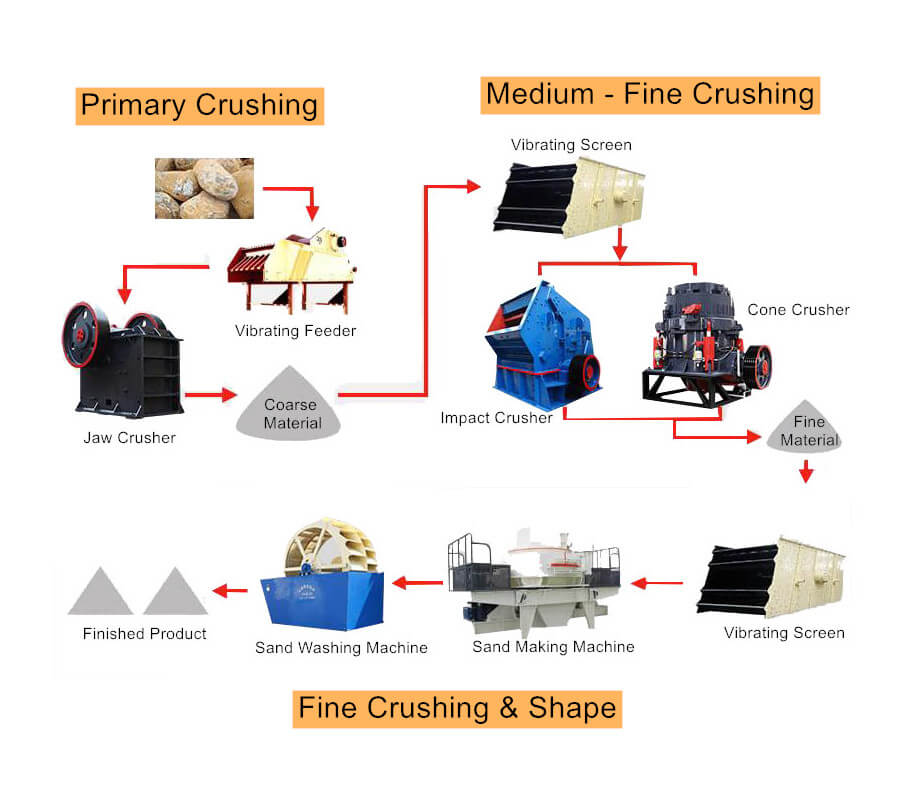

1. Pre-Washing & Classification

♦ Rotary Scrubber with Grizzly Screen (40mm bars)- Removes +40mm waste rocks

- Breaks down sticky clay & scrubs liberated minerals

- Classifies material into 0-2mm (fine concentrate) & 2-40mm (coarse waste)

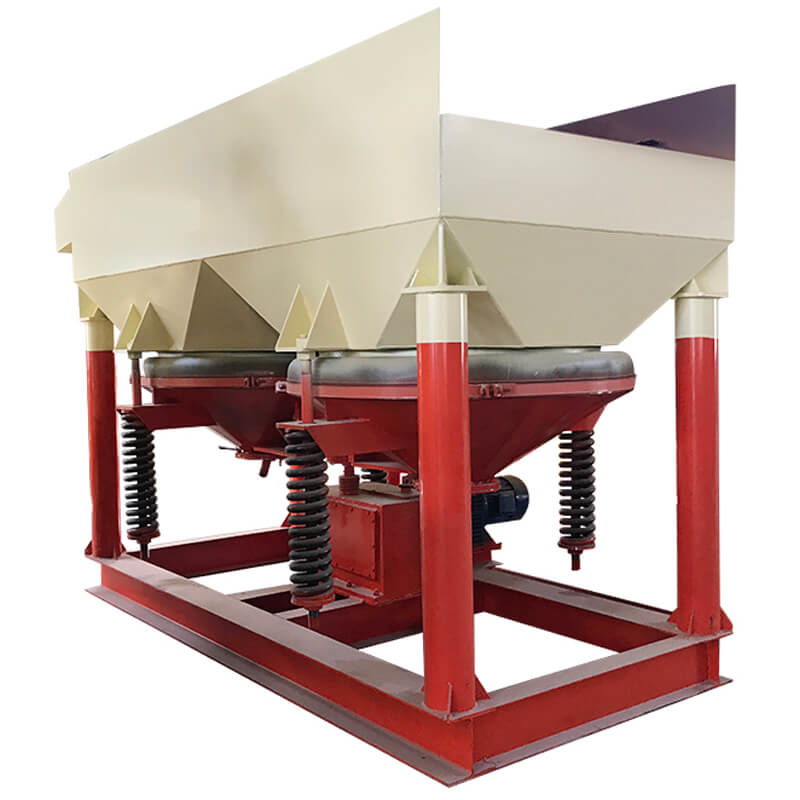

2. Primary Gravity Concentration (Jig Concentrator)

♦ JT1-1 Jig Concentrator- Pulsating water flow stratifies minerals by density

- Recovers 85%+ heavy minerals (Ta/Nb-rich fraction)

3. Secondary Gravity Upgrade (Shaker Table)

♦ 2100×1050mm Shaker Table- Further concentrates 0-2mm material from the jig

- Achieves high-grade pre-concentrate (~30-50% upgrade)

4. Final Magnetic Separation (Dry Magnetic Separator)

♦ 3PC-500 Three Disc Dry Magnetic Separator- Adjustable gradient magnetic field (800-15,000 Gauss)

- Removes weakly magnetic impurities

- Delivers final Ta₂O₅ concentrate ≥45% purity

Customer Questions & Our Answers

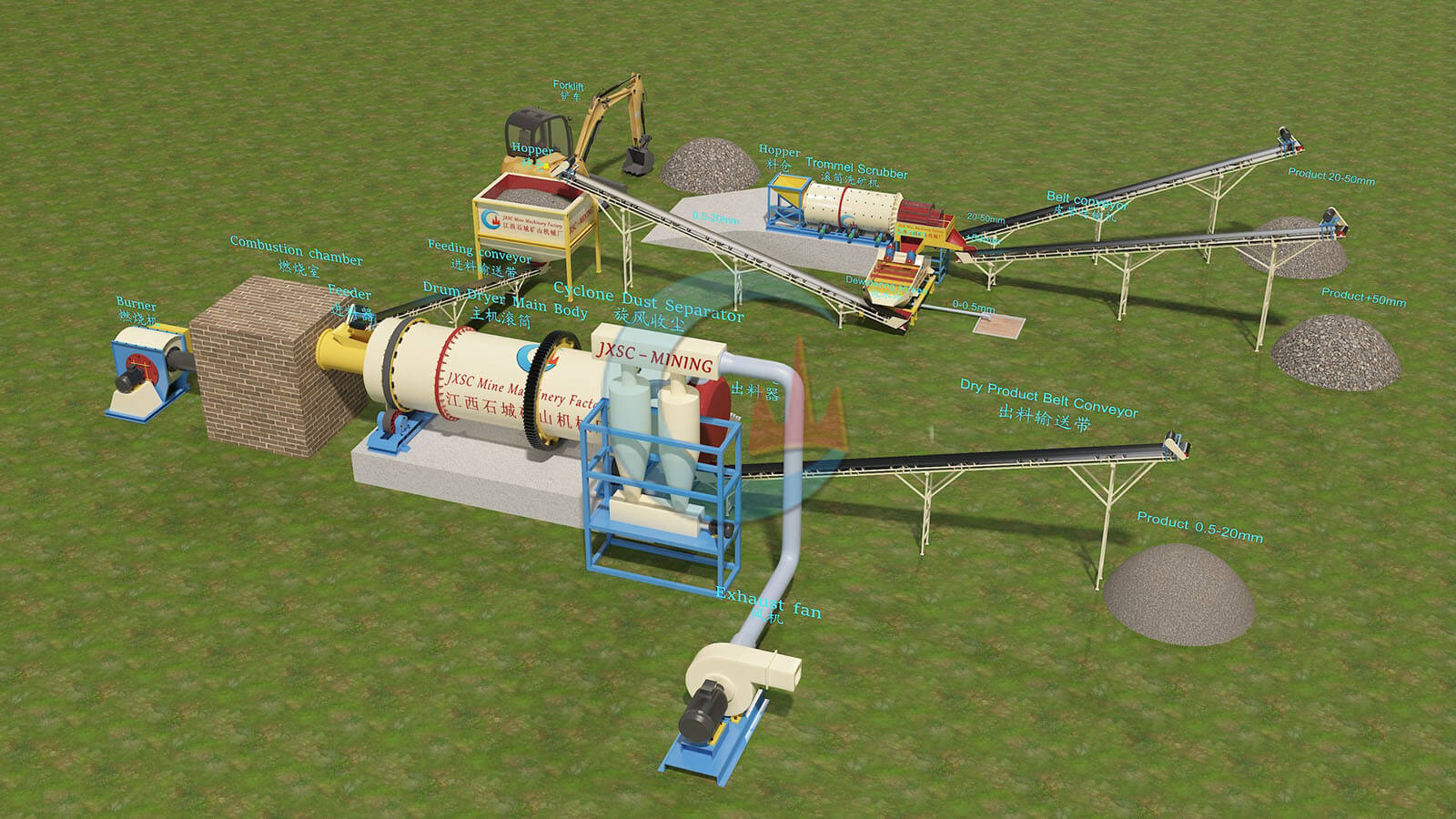

1. What’s the difference between the trommel(rotary) scrubber and trommel screen?

The trommel scrubber is used for washing raw materials with much sticky clay, and the trommel screen is used for washing raw materials with normal sand and soil.

2. What is the particle size requirement for the feed ore?

The maximum feeding size of the trommel is 100mm; it has big waste stones over 100mm. The 100mm grizzly bar(the grizzly bar gap can be customized) can be made on the hopper to remove the big waste stones.

3. How does the jig separator concentrate the alluvial tantalum & niobium?

A jigging machine is a device for mineral separation based on the principle of gravity stratification. Its core mechanism utilizes a sawtooth-shaped, asymmetrical pulsating water flow to stratify mineral particles of different densities and sizes within the jigging chamber, thereby achieving the separation of light and heavy minerals.

4. What’s the function of the shaking table?

The shaking table for re-concentrating the alluvial tantalum & niobium concentrate from the jig separator to reach a higher purity.

5. What’s the water consumption of the whole line of machines?

The total water consumption will need approximately 50 m3 per hour, mainly the backwash water for the jig separator and feeding water for the trommel scrubber, jig separator, and shaking table.

6. Will the 3-piece disc dry magnetic separator be able to separate different minerals?

The three-stage strong magnetic separator is suitable for the separation of various mixed magnetic minerals. Based on the differences in the magnetic properties of the minerals, the magnetic field strength can be adjusted by controlling the excitation current of each disk to achieve efficient separation. The induction distance between each disk and the mineral particles can also be adjusted to obtain different magnetic field strengths, allowing for the simultaneous separation of multiple minerals. This equipment is widely used in the dry separation of ilmenite, monazite, tungsten-tin ore, tantalite, and other minerals containing both magnetic and non-magnetic components.

7. Can you provide the civil foundation drawing of the complete machine line?

Once we receive your deposit payment, our engineer will design the detailed plant layout drawing, foundation drawing for you, and also each main machine’s drawing & machine operation manual. All the technical support will be provided to assist with the installation.

Equipment In This Project

We are a leading provider of innovative and efficient mining equipment and solutions. With years of experience in the industry, we specialize in designing and manufacturing high-quality machines tailored for various mineral processing needs, including gold, diamond, copper, tin, manganese, chrome, titanium, and other ore separations. Our commitment to technology and customer satisfaction drives us to deliver customized solutions that enhance productivity and ensure environmentally sustainable practices. Explore our extensive portfolio of successful case studies and discover how JXSC can transform your mining operations, helping you maximize your profitability while minimizing your ecological footprint. Choose Us—where technology meets efficiency in the world of mining!