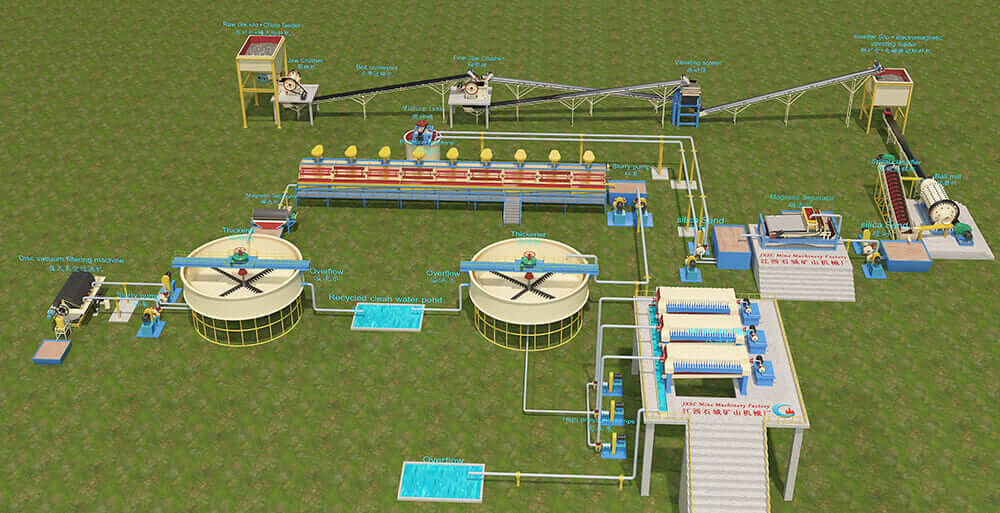

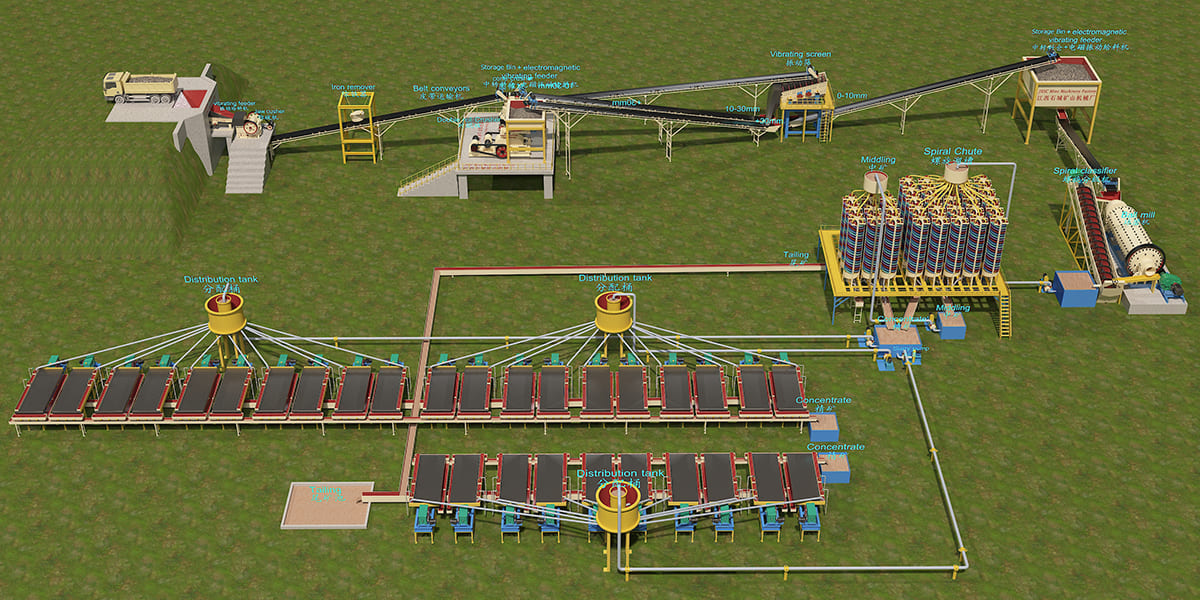

JXSC has provided a successful 50TPH manganese process plant in Kenya. We design the manganese process plant flowchart & plant layout drawing according to ore conditions, provide a complete set of plant machines and send Chinese engineers to the mine site for plant installation & commissioning guidance.

EPCS

Engineering, Procurement & Construction Services

Case Study: Rock Manganese Ore Process Plant Project

Project Overview

Minerals

Rock Manganese

Capacity

50 TPH

Feed Size

≤100 mm

Location

Kenya

Project Process

Solutions & Process

Our factory provided a full set of a 50tph manganese processing plant installed in Kenya. The raw ore information and equipment list are as follows:

Raw ore information

- With sticky clay;

- Max feeding size 100mm;

- Mn concentrate size 0-25mm, need be screened out 0-5mm and 5-25mm

- Processing capacity 50 t/h;

- The proportion of big stones and small stones is over 30mm, about 50%

- Fe content is about 10%

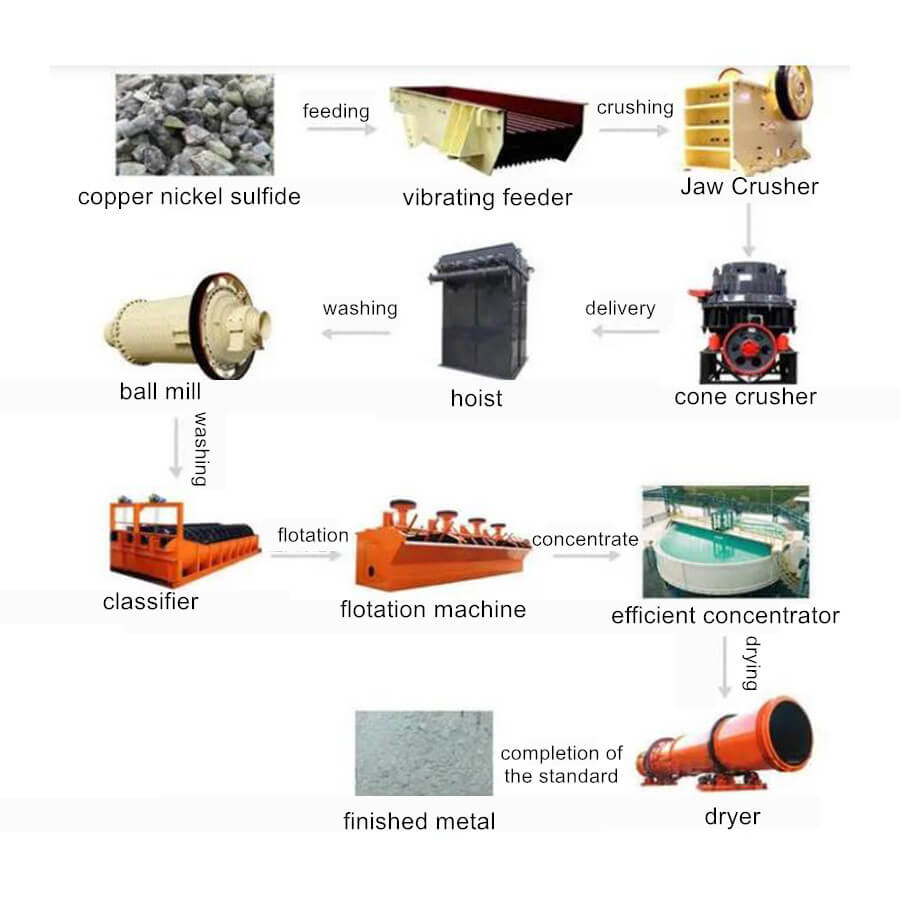

Equipment list includes beow items

- Vibrating feeder

- Trommel scrubber

- Belt conveyor

- Jaw crusher

- Vibrating screen

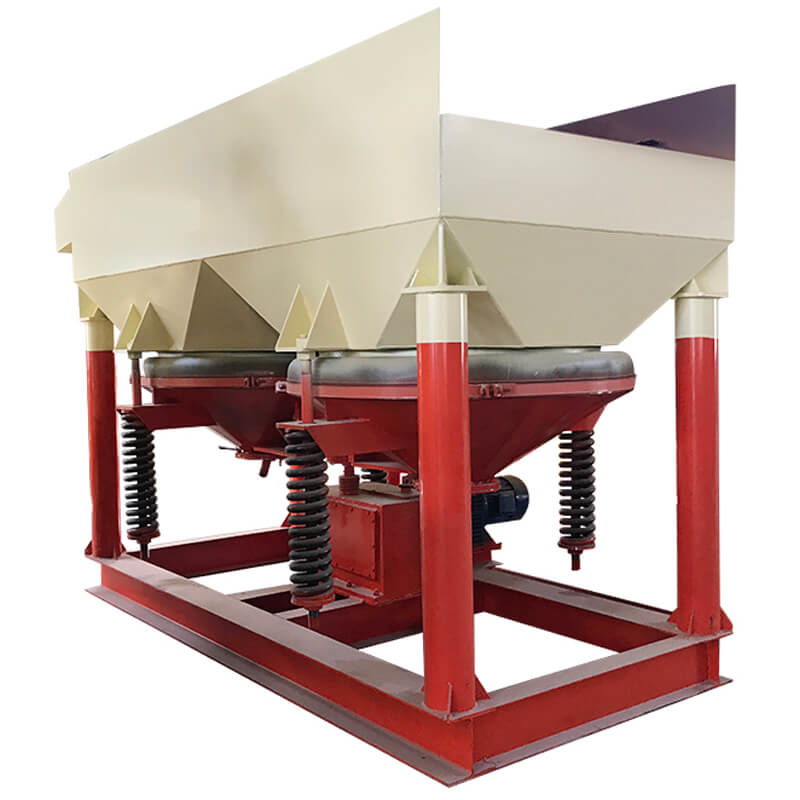

- Jig separator

- Magnetic separator

- Slurry pump

- Water pump

- Full sets of auxiliary equipment for installation

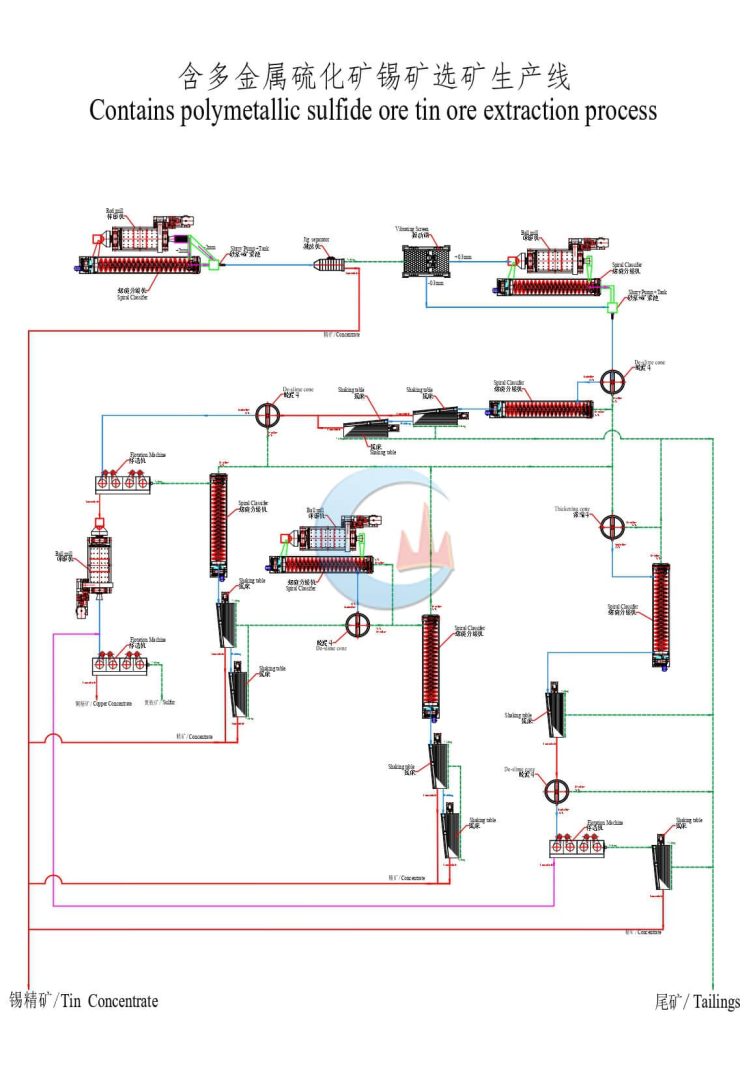

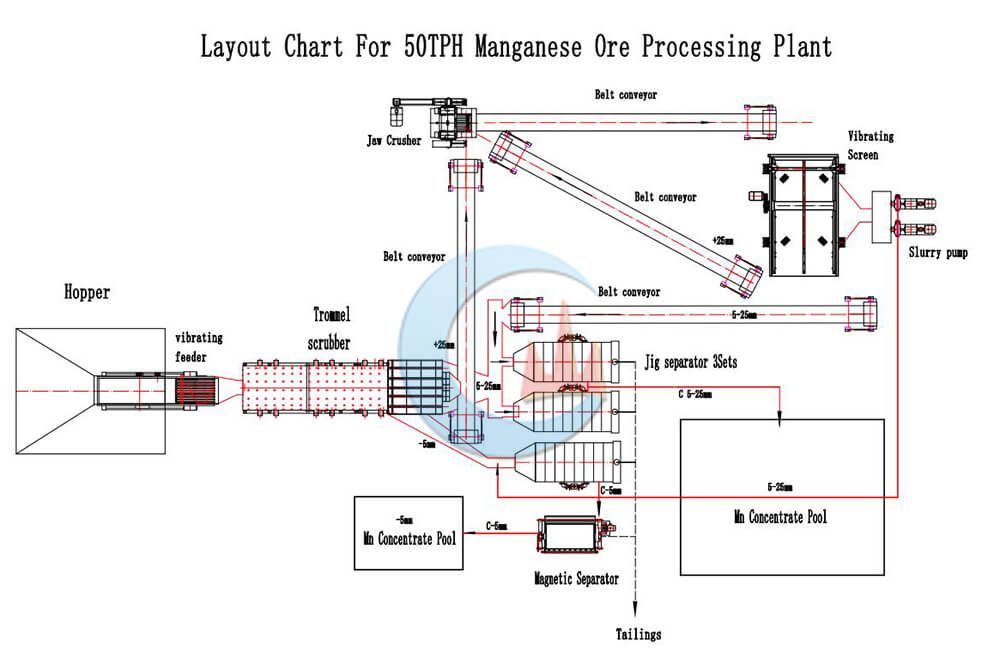

Kenya Manganese Ore Processing Flowchart

JXSC engineers developed an optimized processing flowchart specifically tailored to the client’s ore properties:

Raw Ore Feeding: Material is loaded into the hopper and evenly distributed by the vibrating feeder to the trommel scrubber.

Clay Removal & Initial Screening: The trommel scrubber effectively washes away clay and performs primary classification into three size fractions (0-5mm, 5-25mm, and +25mm).

Multi-Stage Processing:

- 0-5mm fraction: Directed to jig separator for fine manganese concentration

- 5-25mm fraction: Processed through a dedicated jig separator for coarse manganese recovery

- +25mm fraction: Conveyed to jaw crusher for size reduction

Crushing Circuit: Jaw crusher reduces oversized material to 0-40mm, with output sent to vibrating screen for reclassification.

Closed-Circuit Operation: +25mm material from the vibrating screen returns to the jaw crusher, creating an efficient crushing loop.

Gravity Separation: Both size fractions are processed in specialized jig separators for optimal manganese recovery.

Iron Removal: Fine manganese concentrates undergo magnetic separation to remove iron impurities, enhancing final product quality.

Customer Questions & Our Answers

1. How to increase the Mn grade?

Answer: 1st step washing off clay by trommel scrubber; 2nd step removing silica sand by jig separator; 3rd step removing Fe by magnetic separator. After going through these steps, the Mn grade will be increased a lot.

How much the grade can be improved depends on the grade of your raw ore and the proportion of the main mineral components in the raw ore. For example, Mn grade in raw ore is 18%, silica sand is about 50%, Fe content is about 15%, etc. After you provide this data to me, we can calculate how much Mn grade you will get after the process.

2. How does the jig recovery Mn?

Answer: The jig machine belongs to a gravity mineral separator; it can effectively separate heavy minerals from light minerals. The specific gravity of Mn ore is much heavier than silica sand, so it can easily separate Mn ore from sand and recover the Mn concentrates.

Equipment In This Project

Related Cases

We are a leading provider of innovative and efficient mining equipment and solutions. With years of experience in the industry, we specialize in designing and manufacturing high-quality machines tailored for various mineral processing needs, including gold, diamond, copper, tin, manganese, chrome, titanium, and other ore separations. Our commitment to technology and customer satisfaction drives us to deliver customized solutions that enhance productivity and ensure environmentally sustainable practices. Explore our extensive portfolio of successful case studies and discover how JXSC can transform your mining operations, helping you maximize your profitability while minimizing your ecological footprint. Choose Us—where technology meets efficiency in the world of mining!