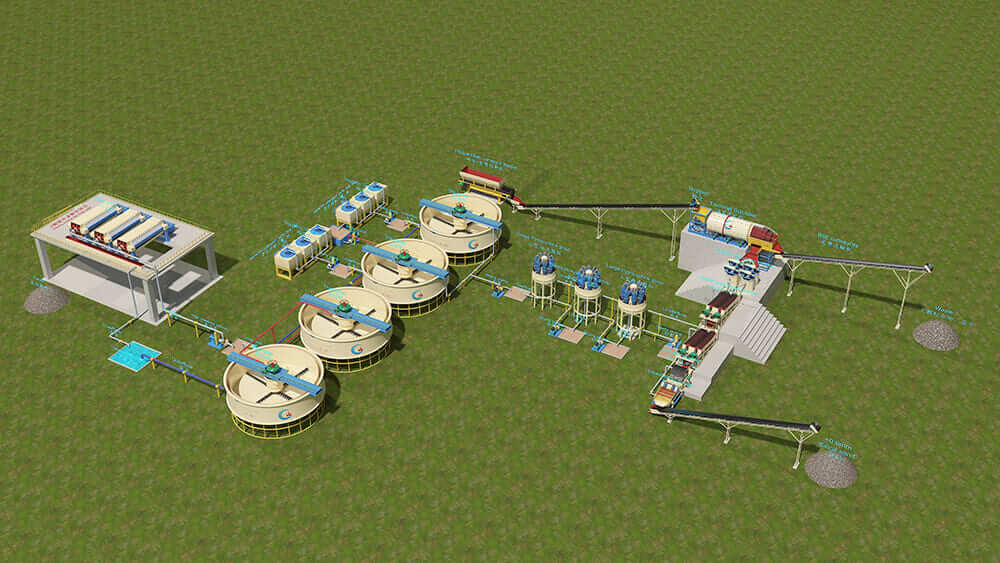

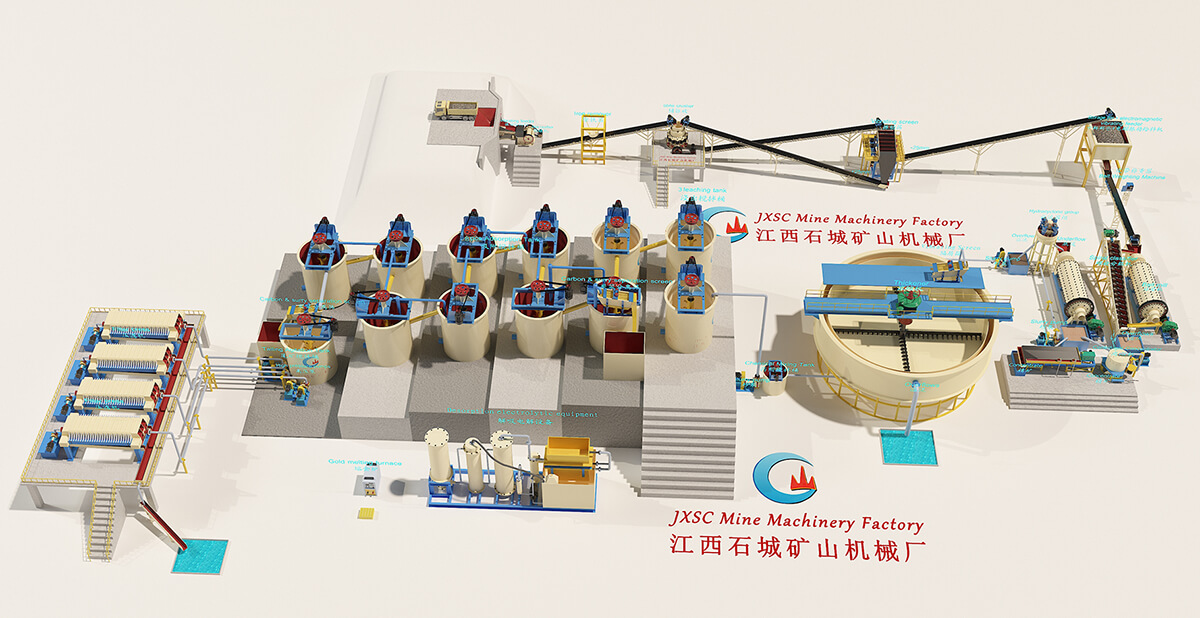

JXSC has successfully delivered a 100TPH alluvial tin ore processing plant in Nigeria. We designed the processing plant flowchart and plant layout drawing according to the client’s requirements. We provided a complete set of plant machines to the mine site.

EPCS

Engineering, Procurement & Construction Services

Case Study: Alluvial Tin Ore Processing Plant Project

Project Overview

Minerals

Alluvial Tin

Capacity

100 TPH

Feed Size

≤400 mm

Location

Nigeria

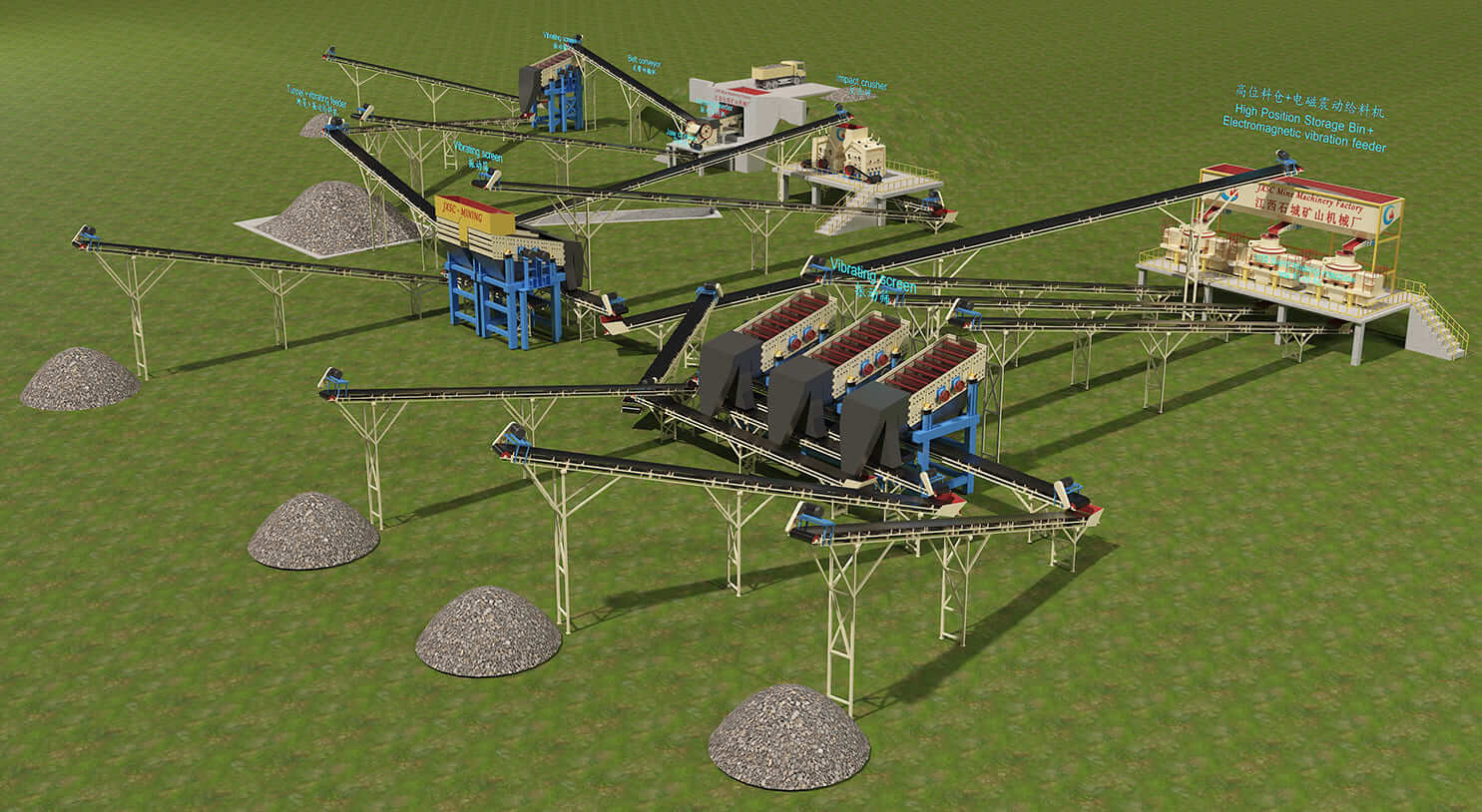

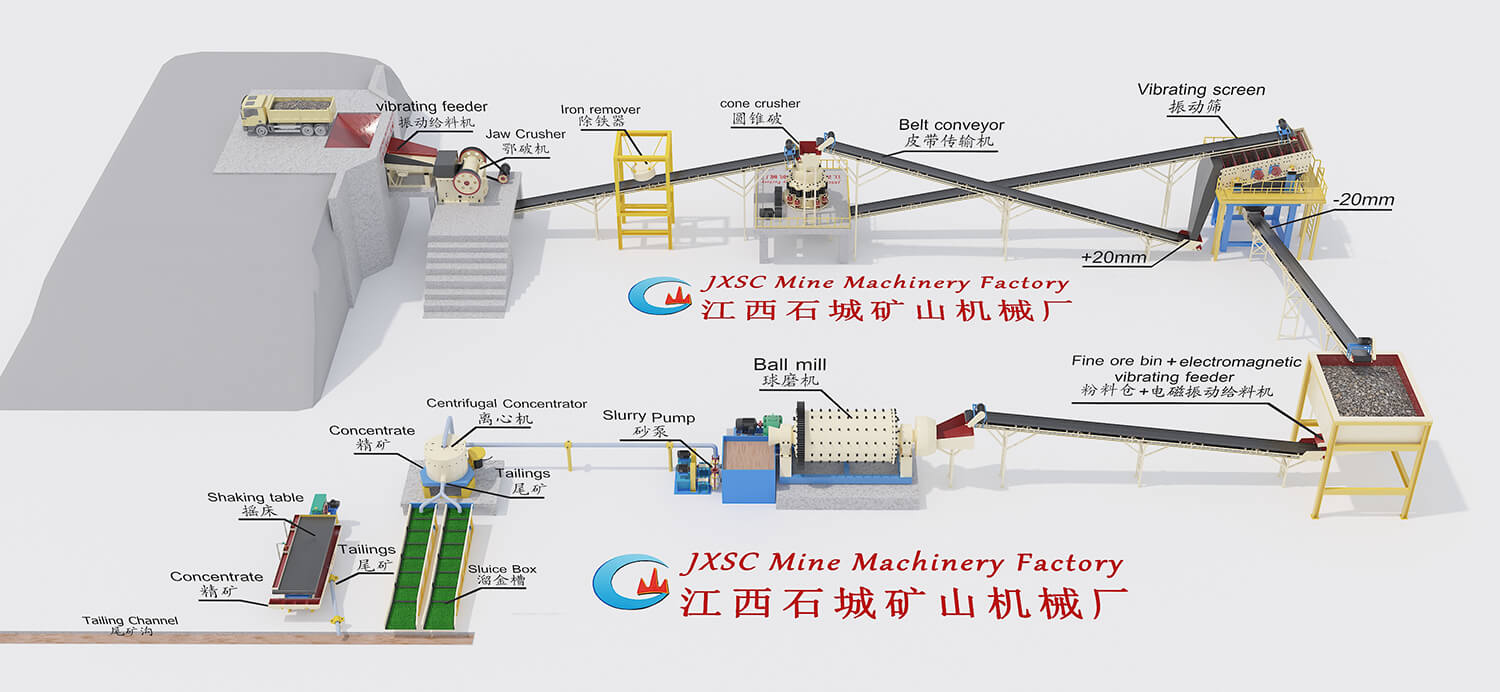

Project Process

Solutions & Process

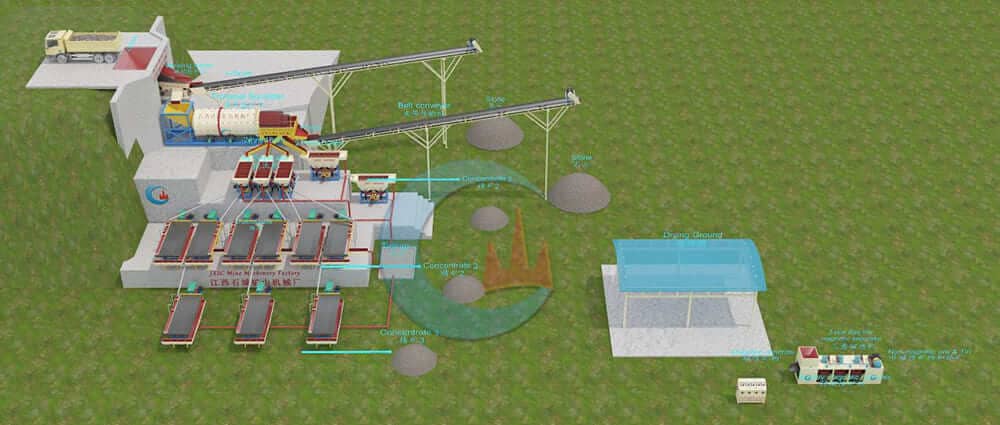

We have provided a full set of 100TPH alluvial tin ore processing plant to Nigeria. The whole line of equipment includes the feeder, trommel scrubber, jig machine, shaking table, three-disc dry magnetic separator, etc

This customer provided his raw ore information as follows:

- Raw materials contain sticky clay

- Tin concentrate particle size 0-7mm, which accounts for 60% in raw materials (0-2mm accounts for 80% and 2-7mm accounts for 20% in concentrate ore)

- Maximum ore feeding size is 400mm

- Processing capacity is 100 tons per hour

This customer told us his requirement for the flowchart design:

- 2-7mm tin concentrate from the 1st stage jig machine need be sent to the 2nd stage jig machine for further separation.

- All 0-2mm tin concentrate from the shaking table needs to be sent to the magnetic separator to further improve the tin grade.

According to the above information and the customer’s requirements, we have designed the most effective process flowchart for this tin project.

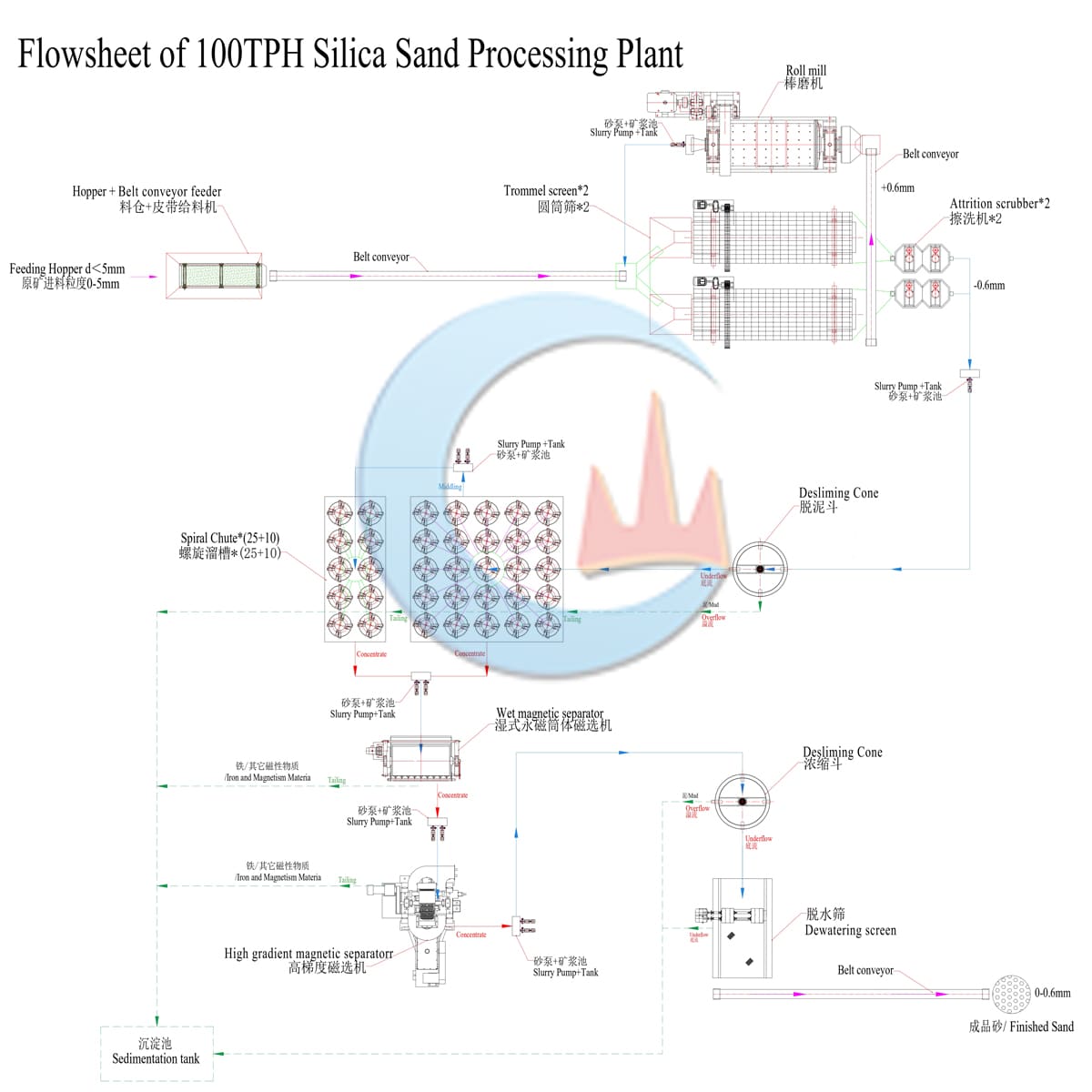

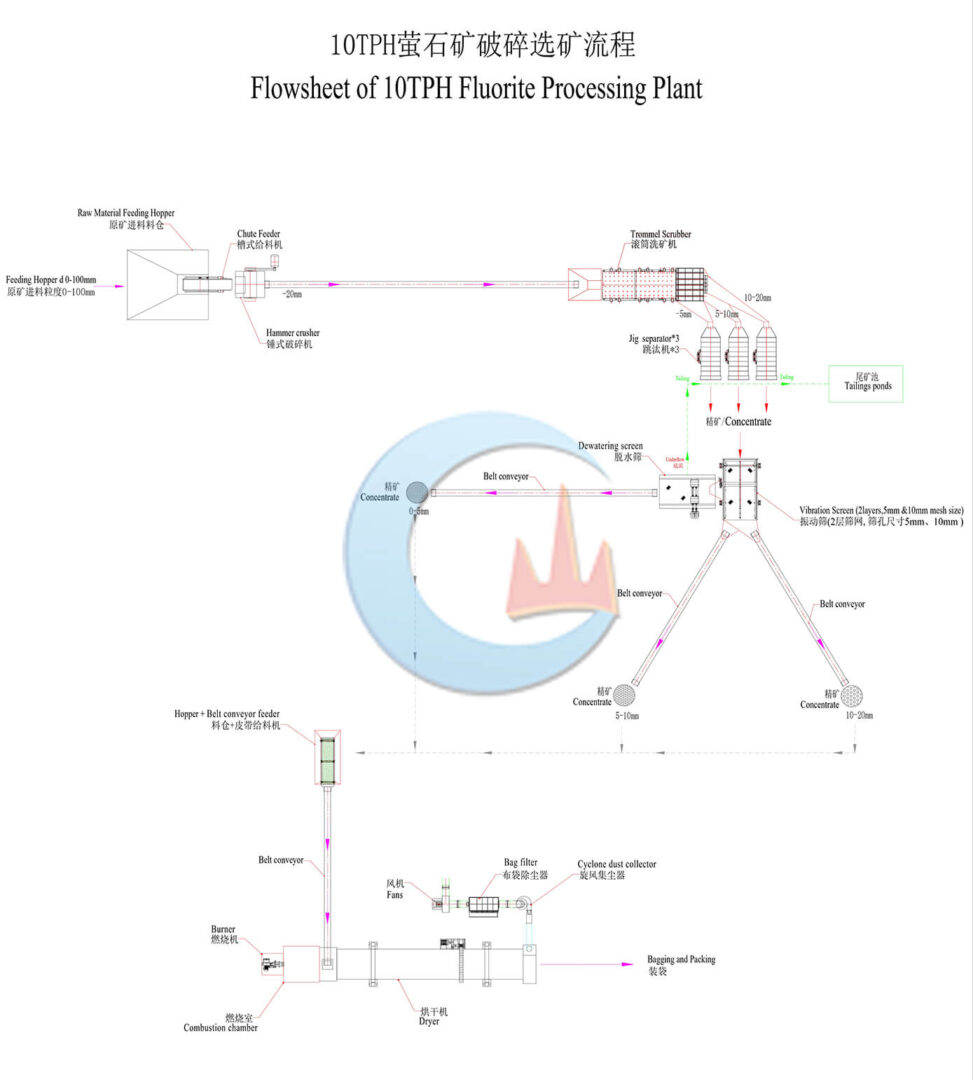

Process Flowchart

Process Design Solution

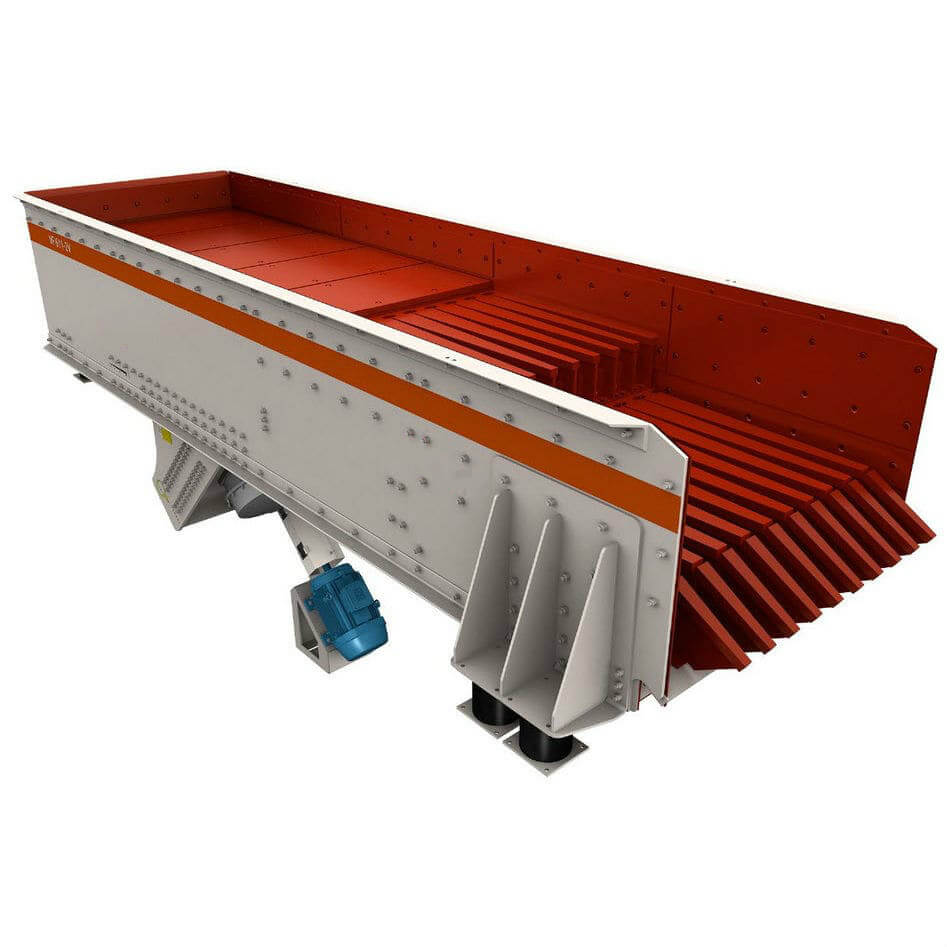

1. Washing system

Raw materials are evenly fed into the trommel scrubber by a vibrating feeder for washing off clay and screening out oversized waste stone. The vibrating feeder is equipped with a grizzly bar (gap 70mm) to remove waste stone over 70mm. The trommel scrubber is equipped with two layers of screen (2mm and 7mm) to sieve out 0-2mm, 2-7mm, and above 7mm waste stone.

Above 70mm big waste stone from the vibrating feeder and above 7mm small waste stone from the trommel scrubber are sent to a far place by belt conveyor.

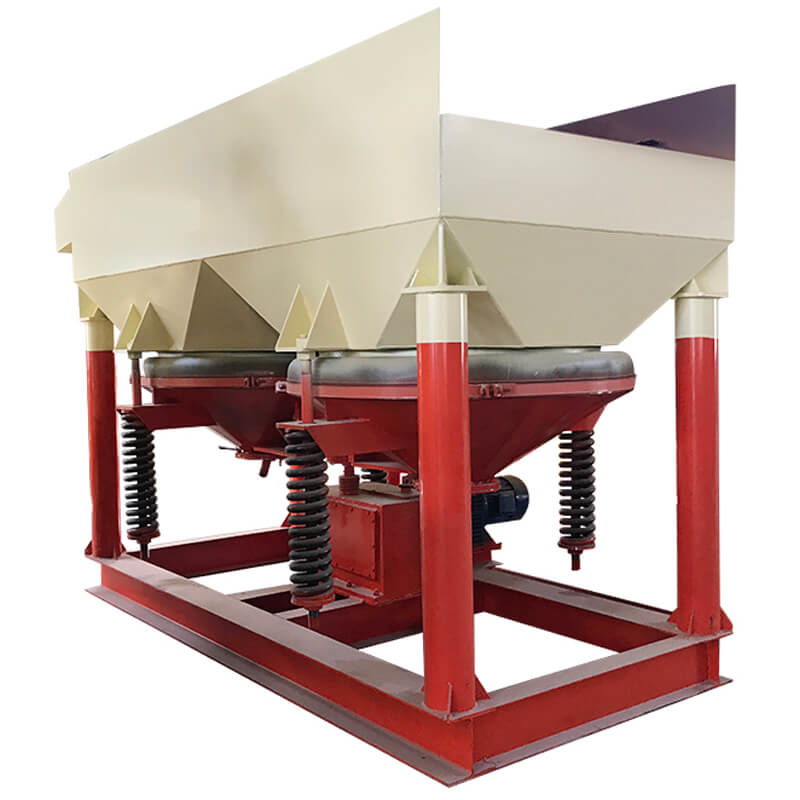

2. Gravity separation by jig and shaking table

0-2mm slurry ore from the trommel scrubber auto flow to the jig machines by gravity for primary concentration of tin concentrate. Tin concentrate from the first stage of jigs is sent to shaking tables for further concentration. In order to improve the recovery rate, middling of shaking tables are sent to the second stage of the shaking table for further processing to recover more tin concentrate.

2-7mm from the trommel scrubber auto flow to another jig machine by gravity for primary concentration of tin concentrate. The tin concentrate goes to the secondary stage of jig for further separation, in order to improve the tin grade. This is the customer’s requirement.

3. Magnetic separation

This customer has a high requirement for tin concentrate grade, so at last, all 0-2mm tin concentrate is sent to three disc dry magnetic separators for further improving the tin grade.

Customer Questions & Our Answers

1. What’s the water consumption for this plant?

Answer: Water consumption for this plant is about 700-800 m3/h

2. What’s recovery for this plant?

Answer: 80% to 85%

3. Does the quotation include the pumps and the motors?

Answer: Yes, the price quoted included pumps and motors. All machines are equipped with motors.

4. Can you send an engineer to conduct the installation for this plant?

Answer: Of course, we can send the engineer to help our customer complete the installation if you need. You just need to pay the engineer’s salary of $150 daily, also need to be responsible for round-trip tickets, visa fee, meals, and lodging for our engineer.

5. Can you have a reference project case to visit the site?

Answer: Yes, we have many successful project cases in Africa, like gold plant, diamond plant, copper plant, etc. If you need to visit our customer’s site, we need to first talk with our customer to get the permit, then we will send our customer’s contacts to you. So you can contact our customer by yourself.

Equipment In This Project

Related Cases

We are a leading provider of innovative and efficient mining equipment and solutions. With years of experience in the industry, we specialize in designing and manufacturing high-quality machines tailored for various mineral processing needs, including gold, diamond, copper, tin, manganese, chrome, titanium, and other ore separations. Our commitment to technology and customer satisfaction drives us to deliver customized solutions that enhance productivity and ensure environmentally sustainable practices. Explore our extensive portfolio of successful case studies and discover how JXSC can transform your mining operations, helping you maximize your profitability while minimizing your ecological footprint. Choose Us—where technology meets efficiency in the world of mining!