JXSC has provided a successful 120TPD spodumene lithium ore processing plant in Zimbabwe. We designed the processing plant flowchart and plant layout drawing according to the client’s requirements. We provided a complete set of plant machines and sent the engineer to the mine site.

EPCS

Engineering, Procurement & Construction Services

Case Study: Spodumene Lithium Ore Processing Plant Project

Project Overview

Minerals

Spodumene Lithium Ore

Capacity

120 TPD

Feed Size

≤100 mm

Location

Zimbabwe

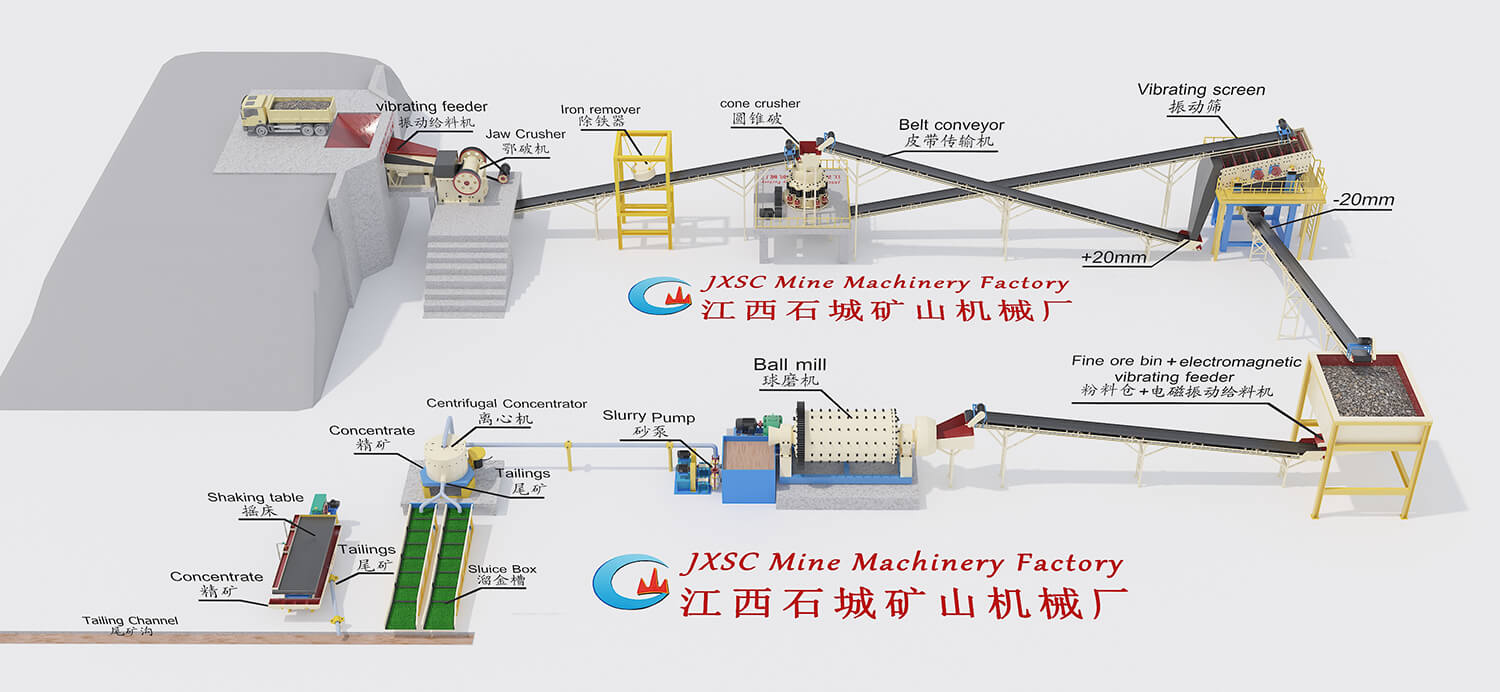

Project Process

Solutions & Process

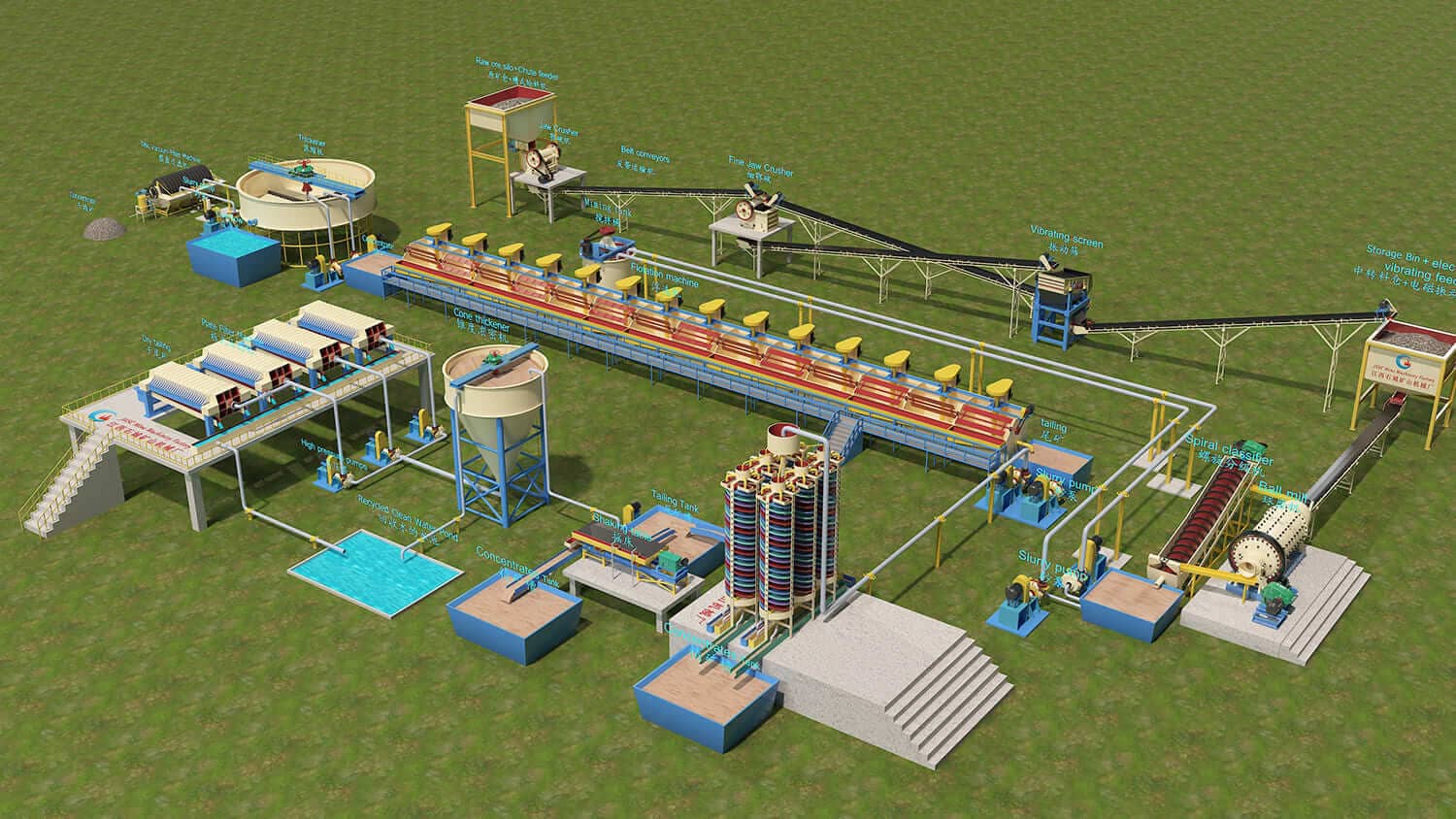

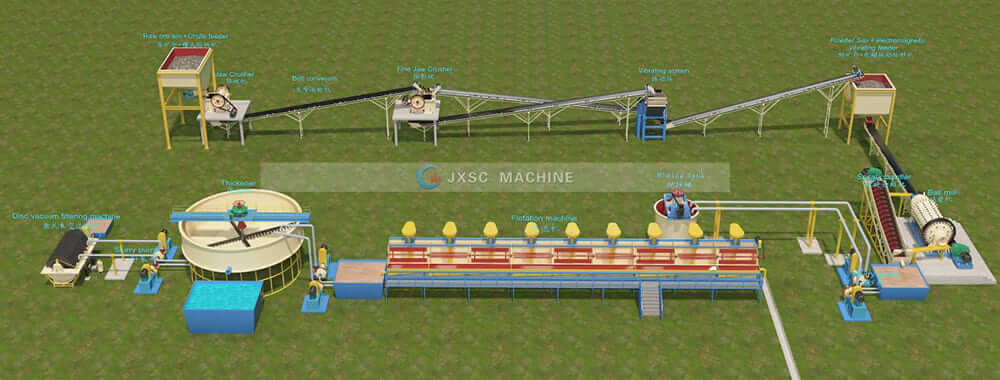

We successfully designed and delivered a comprehensive 120TPD spodumene lithium ore processing facility for our valued client, providing a complete solution that includes crushing, grinding, flotation, and lithium concentrate dehydration systems, along with all necessary auxiliary equipment. The project was customized to meet specific client requirements: processing spodumene lithium ore with a maximum feed size of 100mm at a capacity of 5 tons per hour (120 tons per day). Our team completed the entire facility design and implementation without preliminary ore sample testing, demonstrating our expertise in lithium processing technology and ability to deliver reliable solutions even with limited initial data.

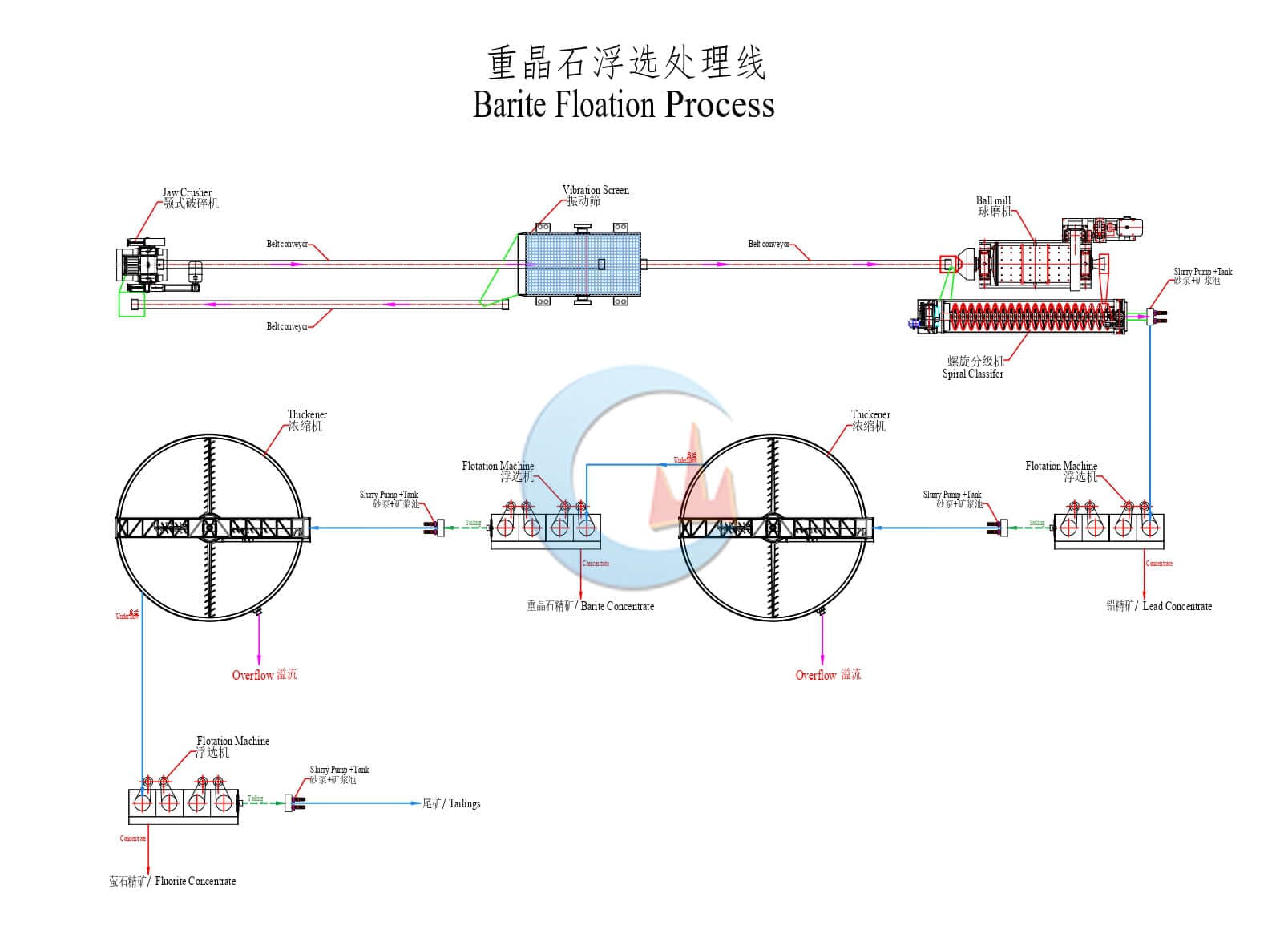

Process Flowchart

Process Design Solution

Based on the client’s requirements, JXSC designed an efficient processing flowchart:

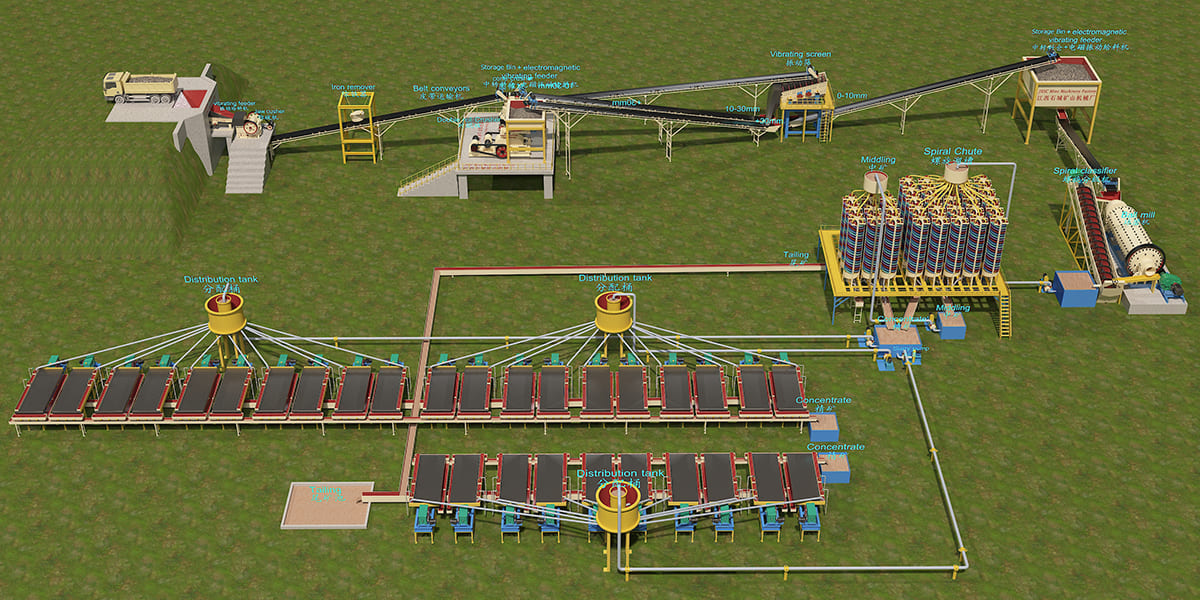

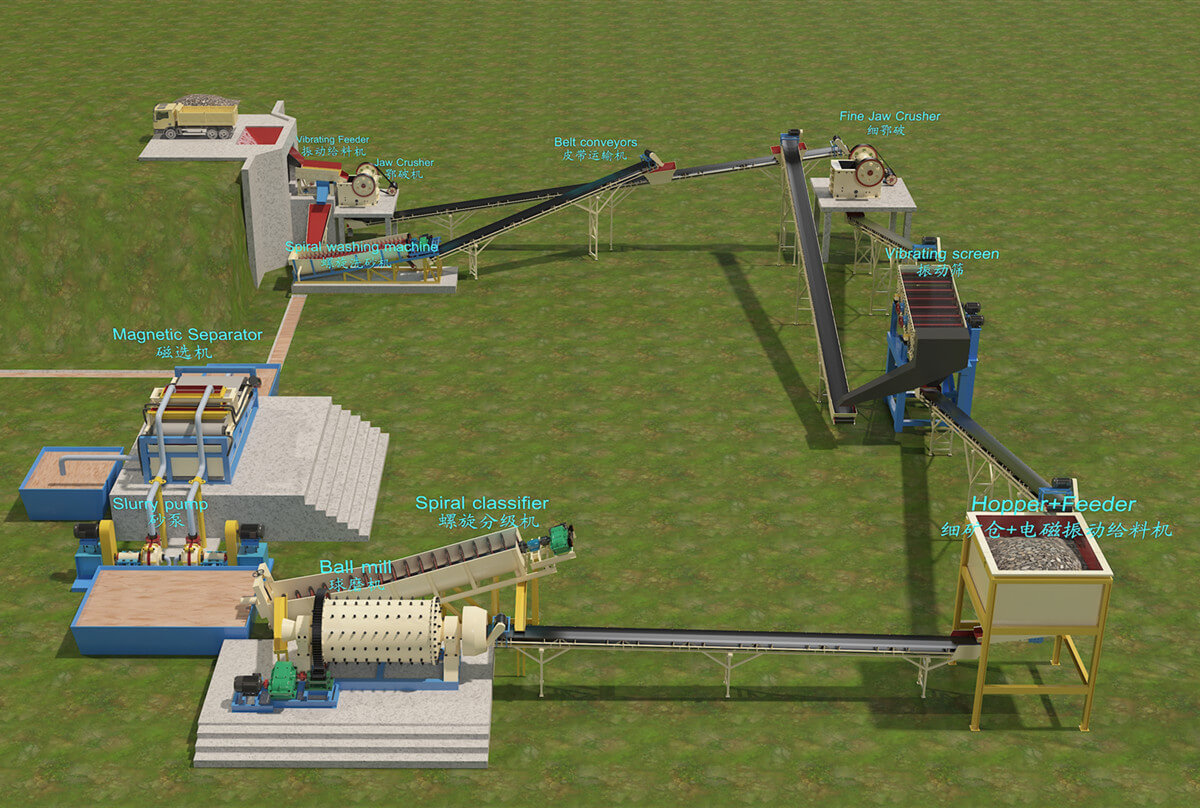

1. Crushing System (10tph, 12 operating hours/day)

Raw ore undergoes a two-stage crushing process:

- The primary jaw crusher receives feed from the raw ore bin via a chute feeder

- The secondary jaw crusher further reduces particle size

- Vibrating screen with 20mm mesh separates material

- Oversize (+20mm) returns to the secondary crusher via conveyor

- Undersized material (-20mm) is transported to the silo for storage

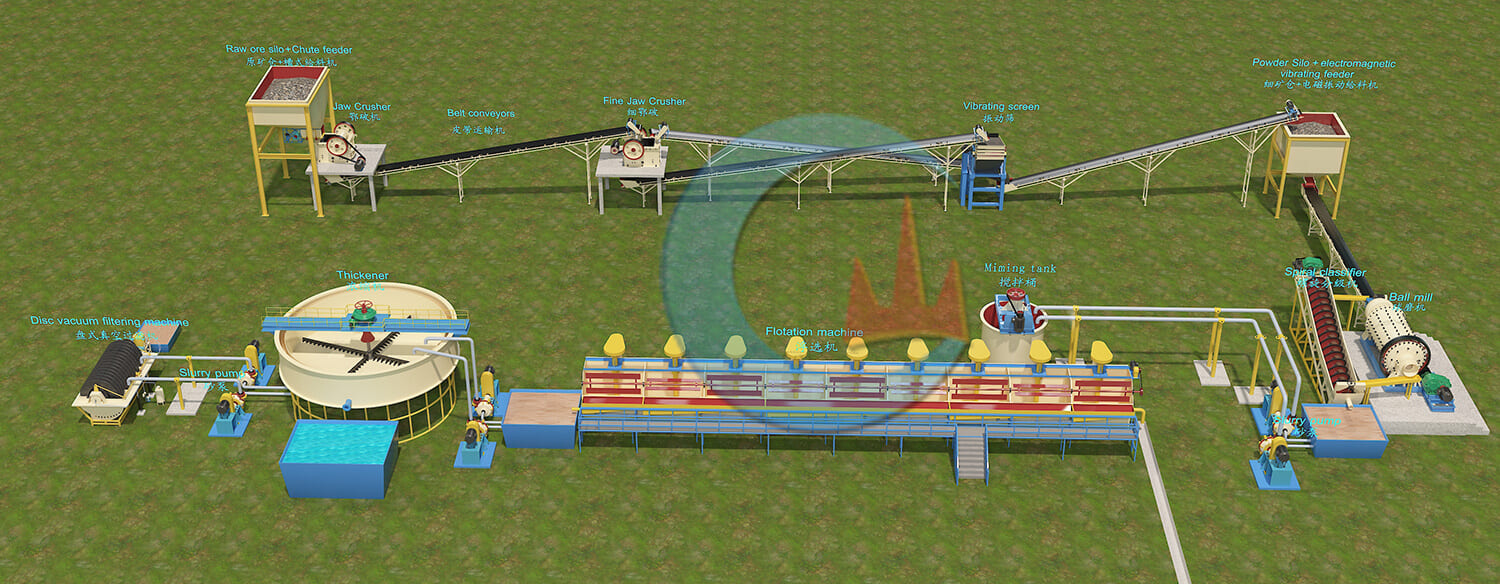

2. Mineral Dressing Process (5tph, 24 operating hours/day)

The beneficiation process utilizes single-stage ball milling with three-stage flotation:

Ball Mill Circuit: Material under 20mm enters the ball mill operating at 25-35% concentration, grinding to 75% passing 200 mesh. A spiral classifier creates a closed circuit with overflow slurry pumped to mixing tanks and dosing systems.

Flotation System: The process includes one rougher stage, one scavenger stage, and three concentration stages. The flotation machines create negative pressure through centrifugal action, drawing in air to mix with ore pulp and reagents, forming mineralized foam that floats to the surface where it’s collected by scrapers.

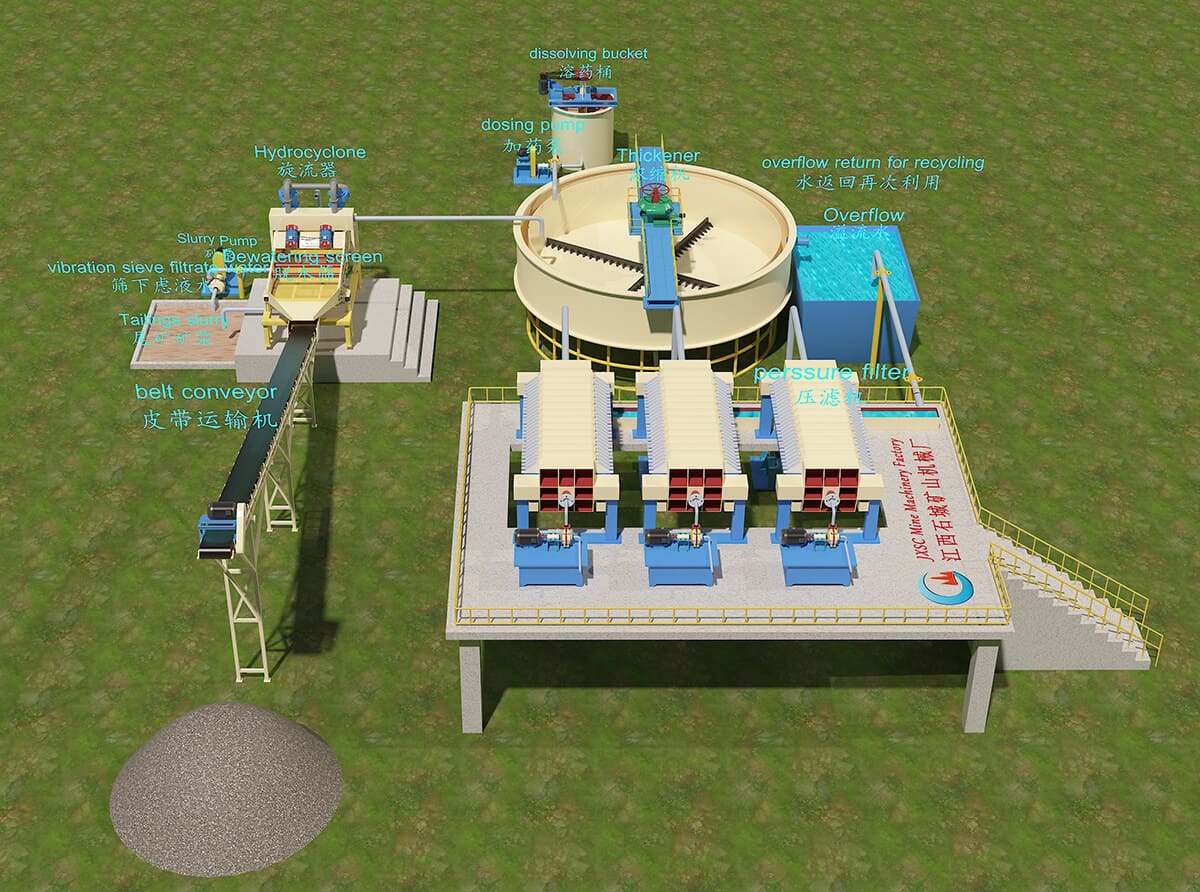

3. Lithium Concentrate Dehydration

A two-stage dehydration process ensures optimal moisture content:

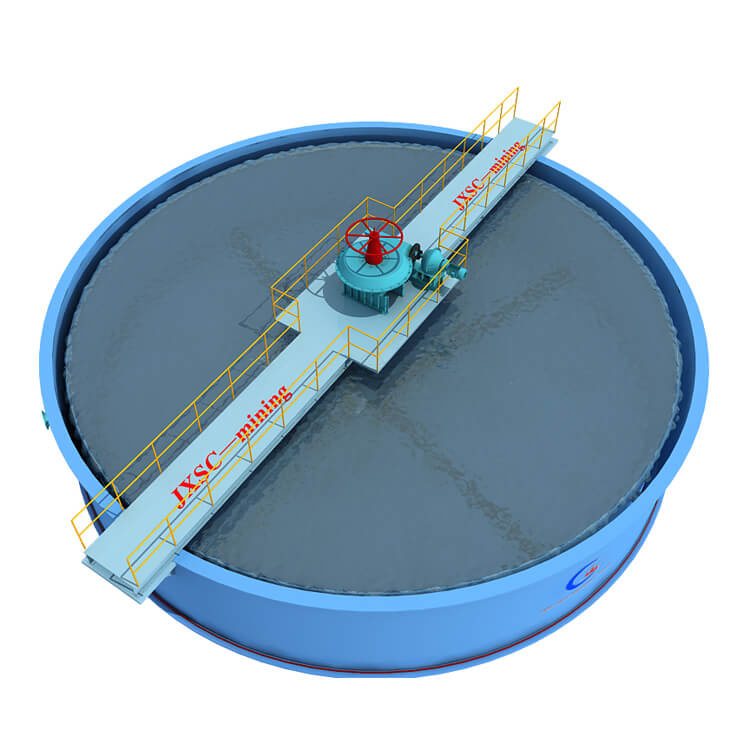

- First stage: Deep cone thickener

- Second stage: Disc vacuum filter

- Final concentrate contains approximately 15% moisture content, ready for bagging and sale

Customer Questions & Our Answers

1. What’s the recovery for the lithium concentrate?

Answer: 90% up.

2. What chemicals are needed to process lithium?

Answer: Chemicals are needed for processing spodumene lithium ore as follows:

sodium hydroxide(NaOH),

sodium carbonate(Na2CO3),

Sodium hexafluorosilicate,

Oleic acid + Oxidized paraffin wax soap(2:1),

2# Flotation oil

3. Can you help me source these chemicals?

Answer: Sure, we can recommend the chemicals supplier to you.

4. Can you send an engineer to install this lithium plant? I can only buy this plant machine on the condition that you send your engineer for installation.

Answer: Of course, we can send an engineer to help our customer complete the installation if you need. You just need to pay the engineer’s salary of $150 daily, also need to be responsible for round-trip tickets, visa fee, meals, and lodging for our engineer.

5. Can you provide spare parts for this plant?

Answer: Sure, we can provide spare parts as per your requirement.

Equipment In This Project

We are a leading provider of innovative and efficient mining equipment and solutions. With years of experience in the industry, we specialize in designing and manufacturing high-quality machines tailored for various mineral processing needs, including gold, diamond, copper, tin, manganese, chrome, titanium, and other ore separations. Our commitment to technology and customer satisfaction drives us to deliver customized solutions that enhance productivity and ensure environmentally sustainable practices. Explore our extensive portfolio of successful case studies and discover how JXSC can transform your mining operations, helping you maximize your profitability while minimizing your ecological footprint. Choose Us—where technology meets efficiency in the world of mining!