Zimbabwe 20TPH Alluvial & Rock Tin Tantalite Ore Processing Plant

JXSC has provided a successful 20TPH alluvial mixed rock tin tantalite ore processing plant in Zimbabwe. We design the ore process plant flowchart & plant layout drawing according to ore conditions and provide a complete set of plant machines.

Alluvial & Rock Tin Tantalite Ore Processing Plant Project Case

Introduction

Minerals: Alluvial & Rock Tin Tantalite

Capacity: 20 TPH

Ore Condition: Contains a lot of slime

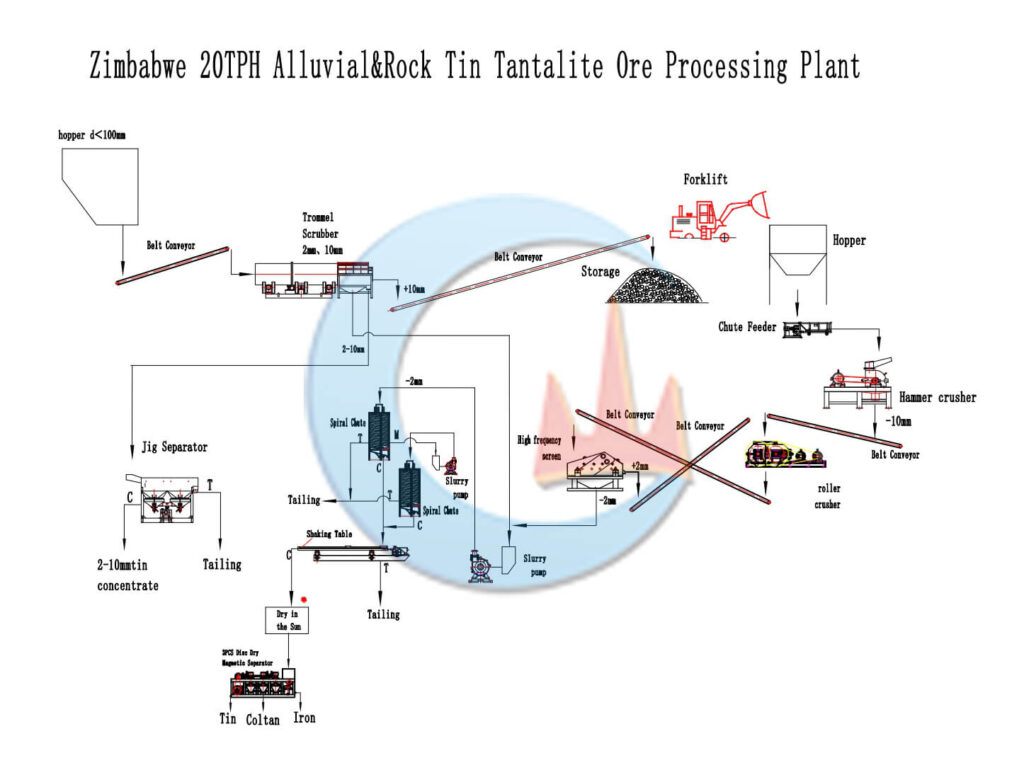

Process: Feeding ->Washing -> Screening -> Crushing -> Gravity separation -> Magnetic separation

Solutions & Process

Tin Tantalite Ore Processing Plant

This setup is an alluvial mixed rock tin tantalite process plant.

- The loader or excavator feeds to one hopper, and we use a belt conveyor to feed the material to the rotary scrubber for washing and screening the raw ore. 0-2mm stone will be put into a pulp pool, and 2-10mm stone will be put into a jig concentrator to select 2-10mm tin concentrate.

- Use the belt conveyor to transport the more than 10mm stone to storage. Then, use a forklift to feed the stone to a hopper and a chute feeder to feed the stone to a hammer crusher; the stone will be 10mm after crushing. Then use a belt conveyor to transport it to the roller crusher to crush it again to 2mm, then use the belt conveyor to transport it to the high-frequency screen to screen out the sand of more than 2mm, and use the belt conveyor to transport it back to the roller crusher to crush it again.

- After the screen, the 0-2mm sand will flow into the pulp pool(the same pool as the discharge of the rotary scrubber 0-2mm). A slurry pump feeds the spiral chute’s 0-2mm sand.

- Use a two-stage spiral chute; the first stage processes 0-2mm sand; the spiral chute has three discharges: concentrates, middlings, and tailings. Then, use a slurry pump to pump the middlings to the next stage to recover. Then, the tantalum concentrates of two-stage spirals are put into a shaker table to recover fine tantalum.

- Dry the tin in the sun, and then use a 3pcs disc dry magnetic separator to separate the tin, tantalite, and iron.