Dewatering Equipment

JXSC has very strict production management and advanced production technology in dewatering equipment. We own advanced cutting, automatic welding, and boring machines, which make our dewatering machine of high quality and good appearance.

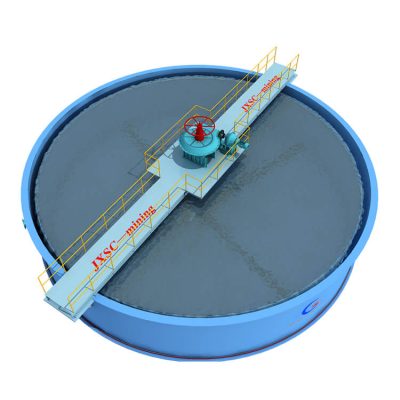

JXSC has been engaged in the production and sales of dewatering equipment since 1985. It is a professional manufacturer of crushers and beneficiation equipment in China. The types of dewatering machines include dewatering screens, rotary dryers, thickeners, plate & frame filter presses, disc vacuum filters, belt filter presses, and so on.

Capacity: 10-250 T/H

Screening sieve hole size: 0.2-0.5 mm

Power: 2.2-30 kW

Capacity: 0.85-1.2 t/h•m2

Filtering Area: 10-120 m2

Filter Tray Quantity: 2-10 pcs

Power: 2.2-15 kW

Filter Areas: 20-500 m2

Filter Plates: 20-128 pcs

Filter Chamber Volume: 0.24-7.96 m3

Power: 2.5-5.5 kW

Capacity: 0.5-30 t/h

Slurry Feed Concentration: 3-8%

Output concentration: 25-40%

Power: 0.75-7.5 kW

High-Performance Dewatering Equipment for Sale

– Maximize Efficiency & Reduce Waste

Looking for reliable dewatering solutions to remove moisture from sludge, tailings, or processed materials? JXSC offers advanced dewatering equipment designed to reduce operational costs, enhance dryness, and optimize recycling across the mining, wastewater treatment, and industrial sectors.

Why Choose Our Dewatering Equipment?

Extract more water for drier discharge or reusable materials.

Save power with low-maintenance, high-capacity systems.

Built with wear-resistant materials for demanding environments.

Tailored configurations for mining sludge, industrial slurries, and municipal wastewater.

We provide comprehensive support, including: free technical consultation and process analysis; customized equipment selection based on your material; installation and operator training; spare parts and maintenance support. Contact Us Today for a Quote!

JXSC Mineral

Mineral processing equipment and solutions-

Application: Flotation process, tailings treatment, ore drying, etc.

-

Function: Reduce the volume of slurry, improve product quality, and reduce transportation and subsequent processing costs.

-

Dehydration Methods: Centrifugal dehydration, filter press dehydration, vacuum dehydration, filtration dehydration, hot air flow dehydration, etc.