Home » Equipment » Dewatering Equipment » Dewatering Screen

Dewatering Screen

The dewatering screen is a device that separates solid and liquid through high-frequency vibration + screen drainage.

Capacity: 10-250t/h

Motor Power: 2.2Kw-30Kw

Screening Sieve: PU screening sieve

Screening sieve hole size: 0.2-0.5mm

Main applications:

- Dewatering ore slurries (such as tailings, concentrates, and coal slimes);

- Drainage after sand and gravel aggregate washing;

- Sludge thickening in wastewater treatment.

Dewatering Screen Overview

Dewatering screen, the main function is dehydration, de-sludge, de-medium, can be used for sand washing in sand and gravel plant, coal slurry recovery in the coal preparation plant, dry discharge of tailings in the mineral processing plant, etc., so it is also called sand and stone dewatering sieve, mining dewatering sieve, slime dewatering screen, tailings dewatering screen, etc.

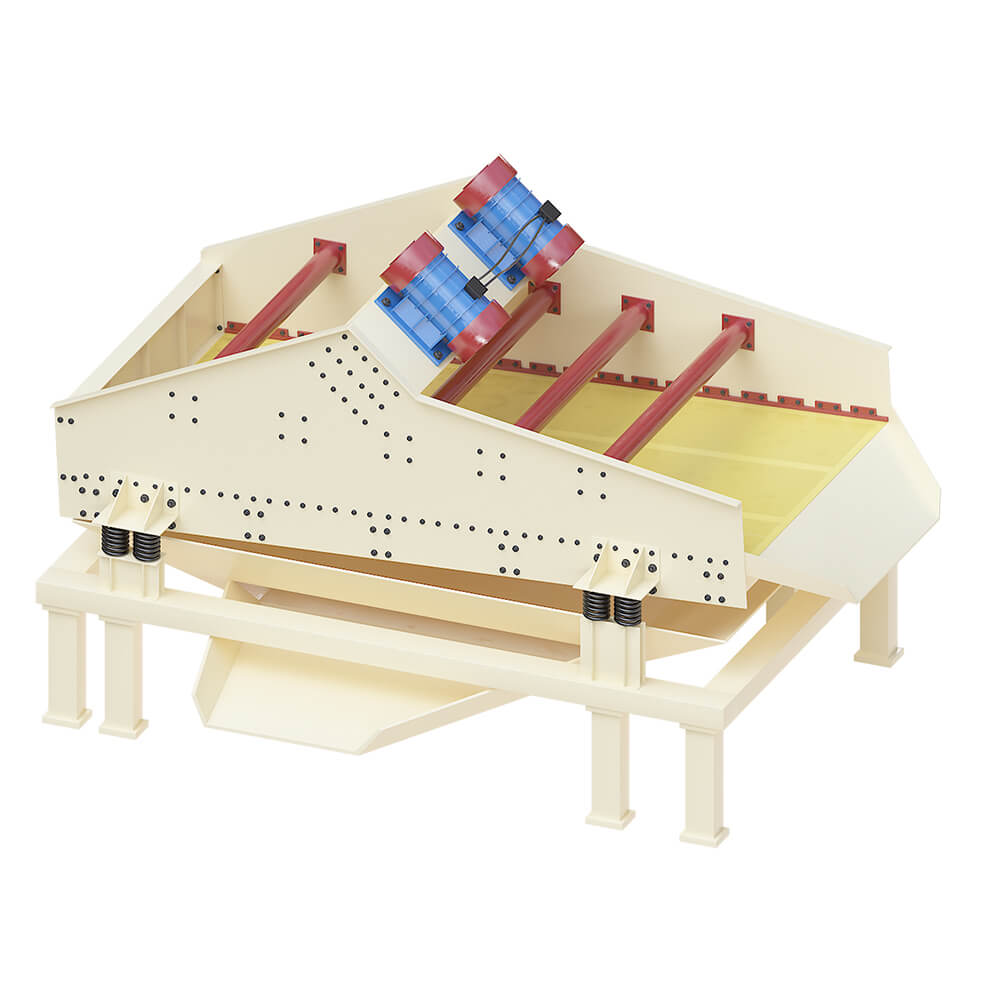

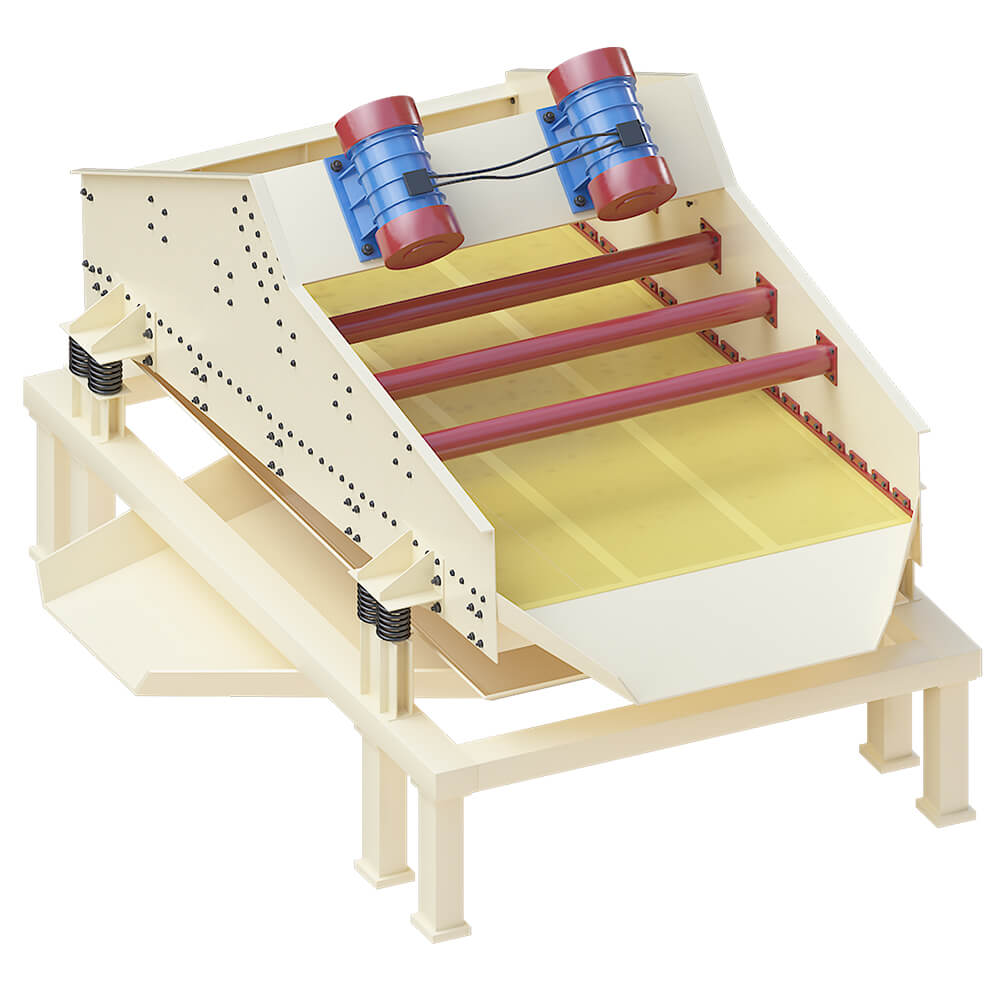

The high-frequency dewatering screen is multifrequency with large capacity and full dehydration. It adopts a method of drilling holes on the side of the sieve plate, allowing part of the water to flow out of the hole quickly, speeding up the dehydration speed, and also avoiding the damage caused by water splashing on the motor.

Custom High-frequency Dewatering Screen

The layer of the screen can be a single layer or multilayer. The screen material is usually chosen PU, but you can choose the other material according to your need.

Advantages

The dewatering screen stands out for its high-efficiency performance, combining powerful vibration with substantial processing capacity while maintaining a remarkably simple structure for easy operation and maintenance. Its innovative 45° installation angle significantly expands the dewatering area, while adjustable vibration frequency allows for optimized treatment of different ore types. The robust construction features torsional shear-type high-strength bolts connecting side plates to beams, eliminating weld gaps and preventing structural fatigue – a design that prevents side plate cracks during intense vibrating operation. Enhanced with durable polyurethane screens (known for superior elasticity and reduced blockage) and protective PU side-push plates, the equipment effectively withstands material impact while ensuring extended service life across demanding dewatering applications.

✔ Efficient Dehydration

Reducing material moisture content from 30-50% to 10-20% (depending on particle size).

✔ Versatile Design

Simultaneously performs classification and dehydration (e.g., separating 0.2-5mm fine sand from sludge).

✔ Low Maintenance

No complex moving parts, and the wear-resistant polyurethane screen has a long lifespan (3000-5000 hours).

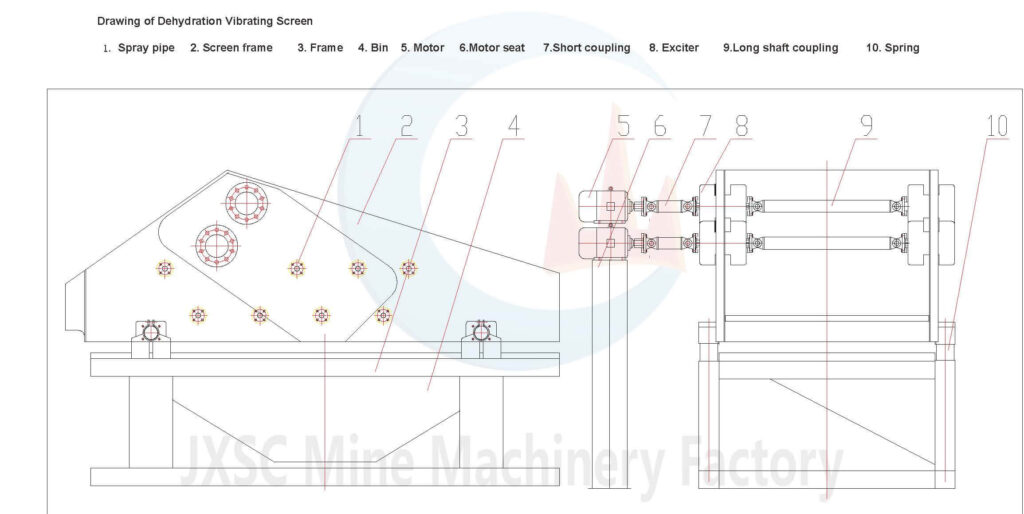

Structures & Working Principle

Dewatering Screen Structure

Dewatering Screen Working Principle

The product adopts a double vibration motor as a power supply: The two motors rotate synchronously and reversely and centrifugal force is produced by two groups of eccentric block. This makes the screen body periodical to-and-fro moving along the direction of a straight line, which is for dehydration. The screen frame is connected by high-intensity bolts, so the structure is stable and durable.

Technical Parameters

| Model | JXSC-1036 | JXSC-1236 | JXSC-1536 | JXSC-1545 | JXSC-1836 | JXSC-1845 | JXSC-2045 | JXSC-2460 |

| Capacity (t/h) | 10-15 | 18-65 | 30-90 | 30-90 | 40-120 | 40-120 | 60-160 | 80-250 |

| Screening Surface Size (mm) | 1000*3600 | 1200*3600 | 1500*3600 | 1500*4500 | 1800*3600 | 1800*4500 | 2000*4500 | 2400*6000 |

| Sieve Size (mm) | Customized according to customer requirements | |||||||

| Double Amplitude (mm) | 0-5 | 0-5 | 0-5 | 0-5 | 0-5 | 0-5 | 0-5 | 0-5 |

| Power (kw) | 2*1.1 | 2*2.2 | 2*3.7 | 2*5.5 | 2*5.5 | 2*7.5 | 2*11 | 2*15 |

| Voltage (v) | 380 | 380 | 380 | 380 | 380 | 380 | 380 | 380 |