Home » Equipment » Crushing & Screening Equipment » Jaw Crusher

Jaw Crusher

Jaw crusher is the core equipment for coarse and medium crushing of medium-hard materials, which is widely used in mining, building materials, metallurgy, and other fields. It crushes materials through the periodic extrusion movement of the movable jaw and the fixed jaw. It has the advantages of a simple structure, strong processing capacity, and convenient maintenance. It is the preferred equipment for primary crushing in the crushing production line.

Capacity: 1-1120 tph

Feeding Size: <1200 mm

Discharge Size: 10-360 mm

Process Material: Granite, dolomite, river pebbles, quartz, calcite, etc.

Jaw Crusher Overview

A jaw crusher is a compression type crusher, usually used as a primary crusher set at the very front of the ore or rock crushing plant to reduce hard rock size. Jaw rock crushers are commonly double-toggle jaw crushers, composed of a fixed jaw and moving jaw, the discharging stone particle size can be controlled by changing the discharge port. Owing to their high crushing capacity and hard material efficiency, jaw crushers are a good alternative to primary gyratory crushers.

Jaw Crusher Types

- Single toggle jaw crushers and double toggle jaw crushers.

- Industrial jaw crushers and laboratory small jaw crushers.

- Diesel engine jaw crushers & Electric jaw crushers.

- Hydraulic jaw crushers

- Stationary & mobile jaw crusher(track mounted jaw crusher).

- PEX / PE jaw crusher.

Advantages

Jaw Crusher Advantages

The jaw crusher delivers superior performance with its advanced swing jaw assembly for enhanced durability and long service life. Featuring an optimized crushing chamber design and large reduction ratio, it ensures high crushing efficiency while the cambered jaw increases plate length for greater capacity. Built with high wear-resistant components, it withstands tough conditions while remaining flexible and versatile across various applications. The advanced crushing process maximizes energy efficiency for cost-effective operation, and its simple structure enables easy operation and quick maintenance. Offering reliable performance at a reasonable price, this jaw crusher is an ideal choice for demanding crushing operations.

✔ High crushing ratio (4-6:1): Large feed size (≤1500mm), adjustable discharge (10-350mm).

✔ Sturdy and durable: High-strength cast steel frame + manganese steel jaw plate, impact and wear resistance.

✔ Strong adaptability: Can crush granite, basalt, iron ore, quartz, and other hard materials.

✔ Low energy consumption: Compared with cone crushers of the same capacity, energy consumption is reduced by 30% to 40%.

✔ Easy maintenance: High automation of the lubrication system, fast replacement of wearing parts.

Structures & Working Principle

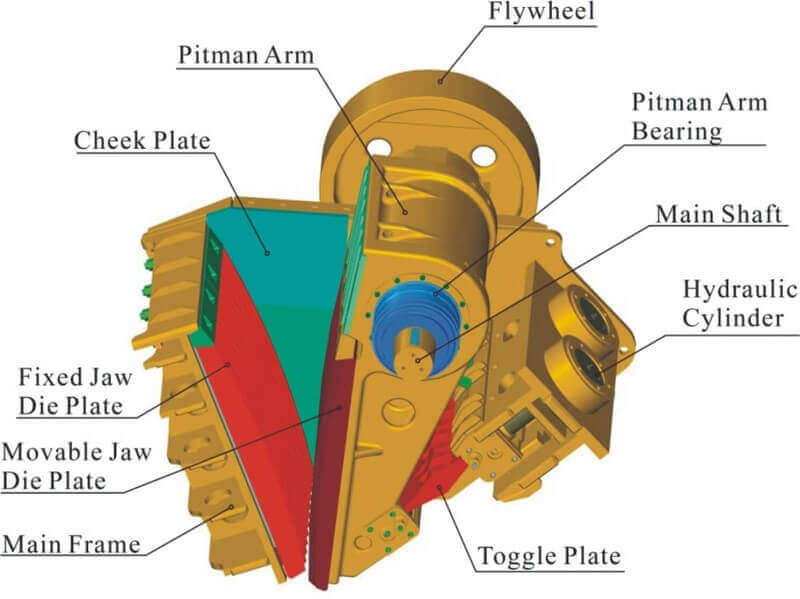

Jaw Crusher Structure

The main parts of a jaw crusher are the flywheel, pitman, hydraulic cylinder, toggle plate, eccentric shaft, fixed jaw, moving jaw, and so on.

Jaw Crusher Working Principle

Motor drive belt and pulley, the eccentric shaft pushes the movable jaw against the fixed jaw, generates the crushing action, and compresses the material to the desired size. The crushed materials are discharged from the discharge port, and the bottom gap of the crusher controls the discharge particle size.

Technical Parameters

| Model | Feeding Size (mm) | Max Feeding Size (mm) | Discharging Range Size (mm) | Capacity (t/h) | Motor Power (kw) | Weight (t) | Overall Dimension (LxWxH)(mm) |

| PE-150*250 | 150*250 | 130 | 10-60 | 3-15 | 5.5 | 2.2 | 1000x1450x900 |

| PE-250*400 | 250*400 | 210 | 20-80 | 5-20 | 15 | 2.8 | 1450x1315x1296 |

| PE-400*600 | 400*600 | 340 | 40-100 | 16-60 | 30 | 6.65 | 1565x1732x1586 |

| PE-500*750 | 500*750 | 425 | 50-100 | 40-110 | 55 | 11.73 | 1890x1916x1870 |

| PE-600*900 | 600*900 | 500 | 65-180 | 80-180 | 55-75 | 16.13 | 2305x1840x2298 |

| PE-750*1060 | 750*1060 | 630 | 80-180 | 110-320 | 90-110 | 28 | 2450x2472x2840 |

| PE-800*1060 | 800*1060 | 680 | 100-200 | 140-340 | 90-110 | 30 | 2610x2556x2800 |

| PE-870*1060 | 870*1060 | 750 | 170-270 | 180-360 | 90-110 | 31.22 | 2660x2556x2800 |

| PE-900*1060 | 900*1060 | 780 | 200-290 | 200-380 | 90-110 | 31 | 2690x2556x2800 |

| PE-900*1200 | 900*1200 | 780 | 95-225 | 220-450 | 110-132 | 49 | 3335x3182x3025 |

| PE-1000*1200 | 1000*1200 | 850 | 195-280 | 280-550 | 110-132 | 51 | 3435x3182x3025 |

| PE-1200*1500 | 1200*1500 | 1020 | 150-300 | 400-800 | 160-220 | 100.9 | 4200x3732x3843 |

| PE-1500*1800 | 1500*1800 | 1200 | 210-360 | 525-1120 | 280-335 | 132 | 5100x4700x4300 |

| PEX-150*250 | 150*250 | 125 | 10-40 | 1-3 | 5.5 | 2 | 896x745x935 |

| PEX-150*750 | 150*750 | 120 | 18-48 | 8-25 | 15 | 3.5 | 1380x1658x1025 |

| PEX-250*750 | 250*750 | 210 | 25-60 | 13-35 | 30 | 4.96 | 1545x1667x1330 |

| PEX-250*1000 | 250*1000 | 210 | 25-60 | 16-52 | 30-37 | 6.5 | 1530x1992x1380 |

| PEX-250*1200 | 250*1200 | 210 | 25-60 | 20-61 | 37-45 | 8.52 | 1900x2192x1430 |

| PEX-300*1300 | 300*1300 | 250 | 20-90 | 25-95 | 55-75 | 12.6 | 1750x2320x1724 |

| PEX-350*1200 | 350*1200 | 300 | 70-140 | 25-120 | 75 | 12.35 | 2162x2220x1723 |