Home » Equipment » Gravity Separation Equipment » Polyurethane(PU) Spiral Chute Separator

Polyurethane(PU) Spiral Chute Separator

The Polyurethane (PU) Spiral Chute is an efficient, gravity-based mineral concentration device, primarily used for low-cost separation of medium-to-fine-grained ores (e.g., iron, tungsten, tin, gold). With its wear-resistant polyurethane construction, it outperforms traditional fiberglass or steel spiral chutes in durability, corrosion resistance, and lifespan, making it a preferred solution in modern mineral processing plants.

Capacity: 0.8-4 tph

Feeding Size: 0.02-0.5 mm

Feeding Density: 25% – 55%

PU Spiral Chute Separator Overview

PU spiral chute separator is a type of equipment commonly used in gravity separation. It utilizes the spiral shape of the chute and the density difference of the material to sort the ore under the effect of gravity.

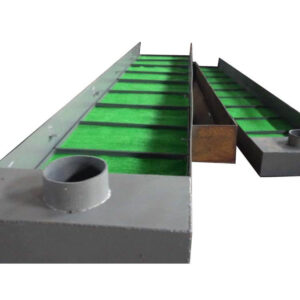

Polyurethane spiral chute separators are made of fiberglass lined with wear-resistant resin and an emery cover; then, paint Polyurethane is added. The abrasion resistance and chemical stability of PU materials make them highly desirable for gravity beneficiation processes. They excel especially with highly abrasive or corrosive ores, eg. they offer significant advantages in the silica sand beneficiation.

Features

- Superior abrasion resistance:PU material has very high abrasion resistance, suitable for processing sand, high-hardness minerals, and other abrasive materials; prolong the service life of the equipment, and reduces the frequency of replacement.

- Chemical stability:PU is resistant to acid and alkali corrosion, can be used in complex chemical environments, adapted to corrosive media in ore processing.

- Lightweight design: lighter than metal, easy to carry and install, reduces transportation and installation costs.

- High separation efficiency: Smooth surface and low friction, good material flow, can improve the efficiency and precision of sorting.

- Modularized structure: The height, inclination, and diameter of the chute can be adjusted according to the characteristics of the ore, processing capacity, and beneficiation requirements.

Scope of application

The application of PU spiral chute separator in gravity beneficiation includes but is not limited to the following minerals:

- Iron ore:for separating iron minerals from veinstone.

- Gold and tungsten ores: to separate high-density precious metal minerals.

- Tin and chrome ores:efficient extraction of heavy minerals.

- Rare earth ores: efficient sorting of rare metals.

- Coal washing: removing high-density impurities in coal and improving the purity of coal.

Due to its wear-resistant, corrosion-resistant, and lightweight characteristics, the PU spiral chute has become an important piece of equipment in gravity beneficiation, and it is especially suitable for handling mineral sorting in highly abrasive and complex environments. Its efficient sorting performance enhances the mineral recovery rate and reduces the cost of mineral processing, which is a high-quality choice in modern mineral processing technology.

Advantages

PU Spiral Chute Separator Advantages

The PU spiral chute separator offers significant advantages for mineral processing through its efficient gravity-based separation technology. Combining cost-effectiveness with environmental sustainability, these lightweight yet durable chutes feature moisture-proof, rust-resistant, and corrosion-proof properties, ensuring extended service life with minimal maintenance requirements. Their simple gravity-powered operation eliminates the need for complex mechanical structures or additional power equipment, making them both energy-efficient and eco-friendly while avoiding chemical use or pollution generation. The optimized spiral design enhances material flow dynamics to achieve superior separation performance, consistently delivering improved recovery rates and higher mineral grades – all while maintaining exceptionally low operational costs.

✔ Extended Lifespan – PU material resists abrasion & impact, lasting 3–5 times longer than fiberglass.

✔ High Recovery Rate – Effective for 0.02–2mm particles, especially fine precious metals (e.g., gold, tungsten, titanium).

✔ Zero Maintenance – No power or moving parts—separation relies solely on gravity and spiral flow dynamics.

✔ Corrosion Resistance – Handles acidic/alkaline ores & seawater processing without degradation.

✔ Modular Design – Can be arranged in single or multi-unit setups, adapting to throughputs of 0.5–10 t/h.

Structures & Working Principle

PU Spiral Chute Separator Structure

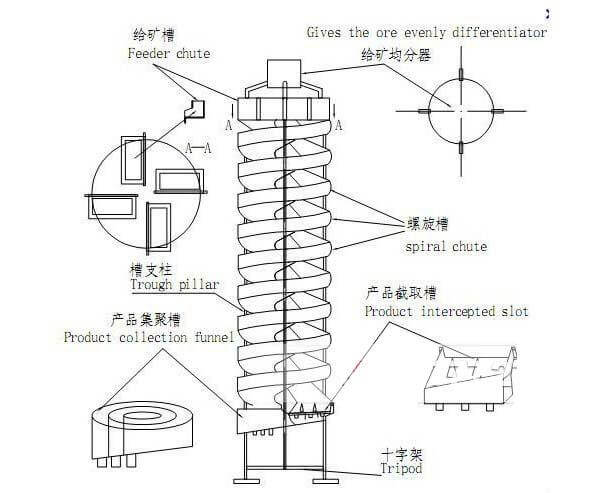

The main parts of a spiral chute are feeder chute, trough pillar, product collection funnel, product intercepted slot, spiral chute, tripod, etc.,

PU Spiral Chute Separator Working Principle

In the beneficiation process, the pulp of the polyurethane spiral chute is subjected to the joint action of inertial centrifugal force and gravity when flowing in the spiral chute. The slurry in the rotary movement generates inertial centrifugal force, prompting light and heavy minerals in the groove surface banding, which are discharged continuously. This sorting principle utilizes the inertial centrifugal force generated in the rotary motion of the slurry, prompting the light and heavy minerals to be separated on the trough surface.

Technical Parameters

| Model | JXSC-600 | JXSC-1200 |

| Outer Diameter | 600mm | 1200mm |

| Spiral Pitch | 320-430mm | 600-630mm |

| Starts Number | 2 | 2 |

| Feeding Size | 0.02-0.3mm | 0.03-0.5mm |

| Feeding Density | 25%-50% | 25%-55% |

| Capacity | 0.8-1.2tph | 2-4tph |

| Dimension | 600*600*2650mm | 1200*1200*3500mm |

| Weight | 70 kg | 132 kg |