Home » Equipment » Auxiliary Equipment » Single Tube Spiral Feeder

Single Tube Spiral Feeder

The single tube screw(spiral) feeder is a continuous feeding device that pushes materials through a closed pipe by a rotating screw shaft. It is particularly suitable for conveying powdered, granular, or small particle materials and can achieve precise metering.

Feeding Capacity: 6-50 m3/h

Power: 2.2-11 kW

Spiral Speed: 34-59 r/min

Application: Mainly used in thermal power generation, cement, paper, mining, forestry, building materials, and other industries.

Single Tube Spiral Feeder Overview

The single-tube spiral feeder is used to convey dry and powder material continuously, such as raw material, coal powder, and cement powder to convey in a short distance. It is used to feed material at the bottom silo.

Features

Material is not easy to block in the inlet. Thus it can guarantee a high filling rate of powder material in conveying pipeline.

Different screw impellers of the inlet opening can mix the material evenly and it will be easy to feed. The structure of the whole screw impeller complies with the conveying regulation of material receiving, providing and steady flow. Thus the even filling rate in the pipeline is guaranteed.

The products of this series have I-fixed speed, II-manual, and no grade tunning speed according to the driving way. All use high-efficiency and high-ratio cycloid pin wheel reducers. Type II is matched with a new electromagnetic tunning speed motor. It is characterized by a wide tunning speed range, stable driving, low noise, and tight structure and it is easy to adjust material flow and meets different manufacturer requests.

The single-tube spiral feeder is widely used in thermal power generation, cement, paper mining, forestry, building materials, and other industries. The equipment runs & discharges smoothly. The tube spiral feeder can operate reliably in harsh environments. And there is a vibration device at the bottom, and the overall structure is compact in design. No material remains in the bag after unpacking.

Advantages

The single tube spiral feeder ensures smooth and consistent material flow with minimal risk of clogging or jamming, providing reliable and uniform discharge performance. Its versatile design allows standalone operation or seamless integration with other equipment to create complete production systems, while the rational structural layout accommodates horizontal, angled, and even vertical installations – potentially replacing elevators for cost-effective material elevation. The fully enclosed construction effectively contains dust emissions for improved environmental compliance and workplace conditions. Engineered for dependable operation with exceptional reliability, this low-maintenance system delivers cost-efficient performance with minimal energy consumption and downtime, making it an economical solution for diverse material handling applications.

Single Tube Spiral Feeder Advantages

✔ Fully enclosed design: Dust- and pollution-resistant, meeting environmental requirements (such as chemical dust recovery).

✔ Precise metering: Flow control is achieved through variable frequency speed regulation (±1-3% accuracy).

✔ Flexible layout: Horizontal, inclined (≤30°), or short-distance vertical conveying.

✔ Low maintenance: No complex transmission components; only regular inspection of bearings and blades is required.

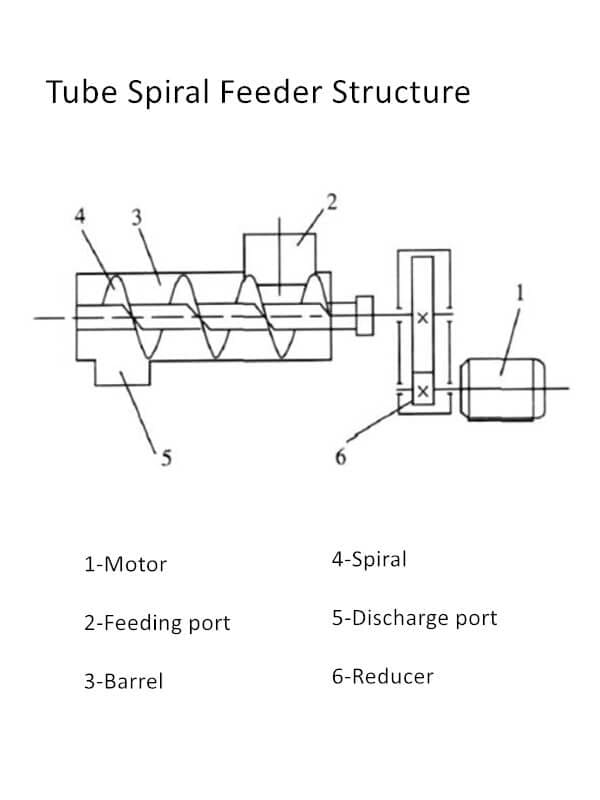

Structures & Working Principle

Single Tube Spiral Feeder Structures

The single-tube spiral feeder is mainly composed of a feed port, spiral blades, cylinder, driving device, discharge port, and other parts.

Single Tube Spiral Feeder Working Principle

During operation, after the material is transported to the casing of the single-tube spiral feeder through the feed port, the material is affected by centrifugal force and tube wall friction in the internal spiral groove, rotates with the spiral blades, and is driven by gravity under the action of gravity. The material slides down along the spiral groove, so that the material is continuously pushed forward and transported, and finally discharged evenly from the discharge port.

Technical Parameters

| Model | Spiral Diameter (mm) | Spiral Pitch (mm) | Feeding Capacity (m3/h) | Spiral Speed (r/min) | Motor Power (kW) | Weigh (kg) | Remark |

| 100 | 100 | 1200 | 6 | 34 | 2.2 | 459 | Single Spiral |

| 160 | 160 | 28000 | 21.3 | 59 | 11 | 3329 | |

| 200 | 200 | 1500 | 30 | 43 | 5.5 | 629 | |

| 250 | 250 | 3000 | 30 | 43 | 5.5 | 881 | |

| 315 | 315 | 4000 | 45 | 43 | 5.5 | 1316 | Double Spirals |

| 400 | 400 | 3000 | 50 | 43 | 5.5 | 1439 |