Home » Equipment » Magnetic Separation Equipment » Three Disc Dry Magnetic Separator

Three Disc Dry Magnetic Separator

The three-disc magnetic separator is a highly efficient magnetic separation device, mainly used for separating fine-grained minerals, especially for separating weakly magnetic minerals from non-magnetic minerals.

Capacity: 100-500 Kg/h

Feeding Size: ≤2 mm

Process Material: Titanium, rare earth ore, tungsten-tin ore, chromite, niobium-tantalum ore, Limonite, Zircon, gold, solitary, feldspar, quartz, and other magnetic differences in a variety of metallic minerals or non-metallic materials of the iron remover.

Three Disc Dry Magnetic Separator Overview

A 3pc disc magnetic separator is used for separating weak magnetic minerals and rare metal ore. It is a very important mineral processing equipment. Three-disc magnetic separators are divided into two types of dry three-disc high-intensity magnetic separators. The magnetic field intensity can be obtained by adjusting the magnetic field current of the magnetic disks to form different intensities to separate the minerals efficiently, and by adjusting the induction distance between the magnetic disks and the selected particles, to achieve one-time separation of a variety of minerals. This equipment is widely used in the dry separation of Ilmenite, monazite, tungsten tin ore, tantalite, and other magnetic and non-magnetic minerals.

Magnetic Separators for Sale

As a professional magnetic separator supplier, we supply various types of magnetic separators, including Dry Drum Magnetic Separator, Wet magnetic separators, Roller Electrostatic Separator, Three-disc dry magnetic separators, High-Intensity Magnetic Separators, and magnetic separator laboratory use equipment. Magnetic separator design service is available.

Advantages

Three-Disc Dry Magnetic Separator Advantages

The three-disc dry magnetic separator comes with several advantages, including a reasonable structure that requires a small floor area, making it space-efficient. It is easy to operate and maintain, enabling straightforward usage for users. This equipment excels in performing a one-time separation of strong magnetic, weakly magnetic, and non-magnetic minerals, making it highly versatile. Moreover, it is particularly well-suited for dry mining operations in areas where water is scarce, enhancing its applicability in diverse mining environments.

✔ High Sorting Precision: The three-disc design ensures uniform magnetic field distribution, effectively separating a wide range of magnetic and weakly magnetic materials.

✔ Versatility: Suitable for sorting a wide range of magnetic materials, especially for fine separation of multi-component materials.

✔ Self-Adjusting Design: The equipment adapts to material changes, improving separation efficiency.

✔ Environmentally Friendly and Energy-Saving: The equipment is easy to operate, reduces water usage, and meets the requirements of sustainable development.

✔ Easy Maintenance: The rational structural design facilitates operation and routine maintenance.

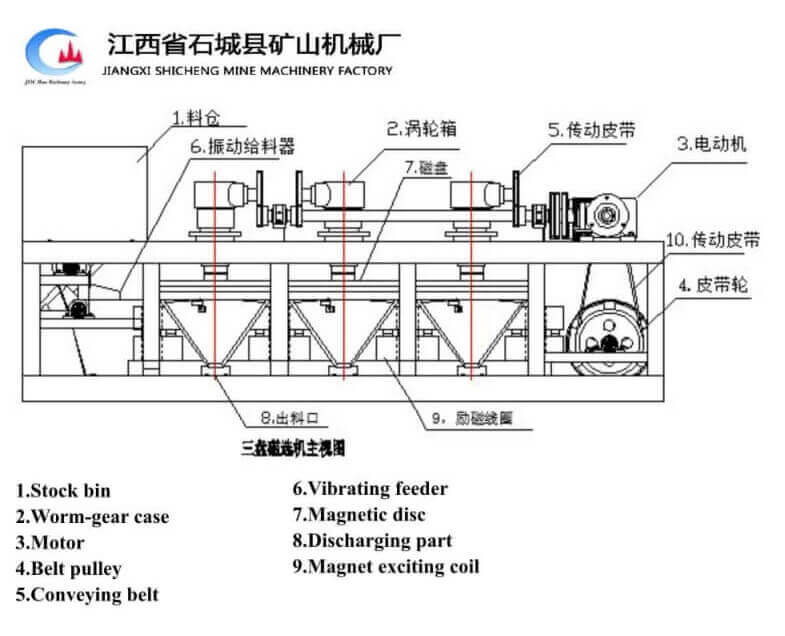

Structures & Working Principle

Three-Disc Dry Magnetic Separator Working Principle

The three-disc dry magnetic separators’ transmission principle is very simple, easy to operate, but also very highly efficient. Three disc magnetic separators into a higher electrical control technology, so that easy to understand production operations, improve work efficiency, and reduce the operator’s labor intensity. There is an adjustable separator in the separator, the separator is made of stainless steel, which can guarantee the service life of the separator effectively and avoid the possibility of rust affecting the mineral quality; the separator can be adjusted flexibly and fixed quickly It plays an important role in ensuring the quality of ore grade in the production process.

Technical Parameters

| Model | 3PC-500 | 3PC-600 |

| Magnetic Intensity(Gauss) | 0-18000 | 0-20000 |

| Number of Magnetic Disks (Pieces) | 3 | 3 |

| Revolution of Magnetic Disk(r/min) | 25-40 | 22-38 |

| Power Supply(V) | 380 | 380 |

| Exciting Coil(Unit) | 4 | 4 |

| Matching Motor(kW) | 0.75 | 1.5 |

| Exciting Power(kW) | 1.5 | 1.6 |

| Feed Size(mm) | ≤2 | ≤2 |

| Capacity(Kg/H) | 100-300 | 200-500 |

| Overall Size(mm) | 2800×800×1220 | 3200×870×1160 |

| Weight(kg) | 1900 | 2200 |