X Ray Diamond Sorting Machine

💎 Revolutionize Diamond Sorting with XRT Technology!

- Unmatched Recovery Rates

- Fully Automated Efficiency

- Industry-Leading Detection

Want Faster, More Accurate Diamond Sorting?

Optimize Your Diamond Recovery with JXSC’s Advanced Mineral Solutions

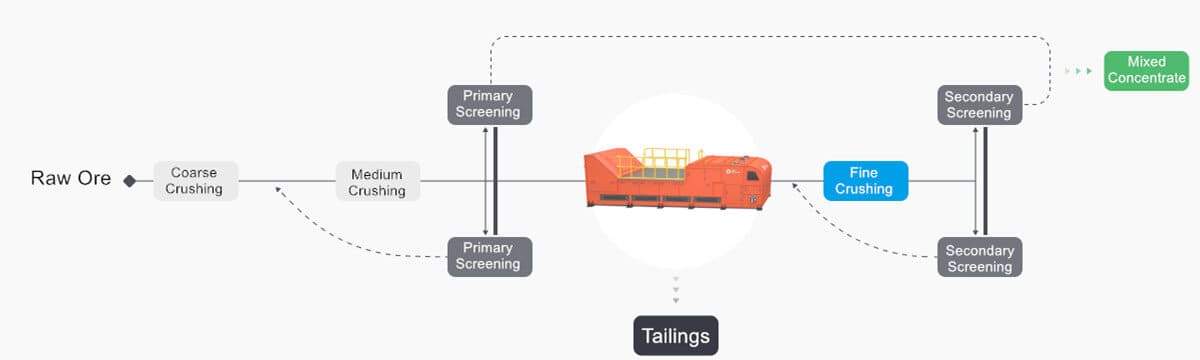

As a leading ore processing solutions provider and mining equipment manufacturer, JXSC specializes in designing high-efficiency diamond recovery plants tailored to maximize yield and profitability. In today’s competitive mining industry, relying on outdated separation methods can lead to significant diamond loss and increased operational costs. That’s why modern operations demand smarter, more precise technology—enter X-ray diamond sorting machines.

Revolutionize Your Diamond Sorting Process with Cutting-Edge X-Ray Technology

In the fast-paced diamond mining and sorting industry, efficiency and accuracy are paramount. Traditional manual sorting methods are no longer sufficient to meet today’s demands—leading to wasted time, resources, and missed opportunities. That’s why advanced X-ray diamond sorting machines are transforming the industry, delivering unprecedented precision, speed, and profitability.

The Future of Diamond Sorting: X-Ray Technology

Modern diamond sorting machines equipped with X-ray transmission (XRT) technology provide unparalleled capabilities for identifying and separating diamonds from waste rock or other minerals. Unlike optical or density-based sorting systems, X-ray sorting machines detect diamonds based on their atomic composition, ensuring exceptional accuracy—even for the smallest stones.

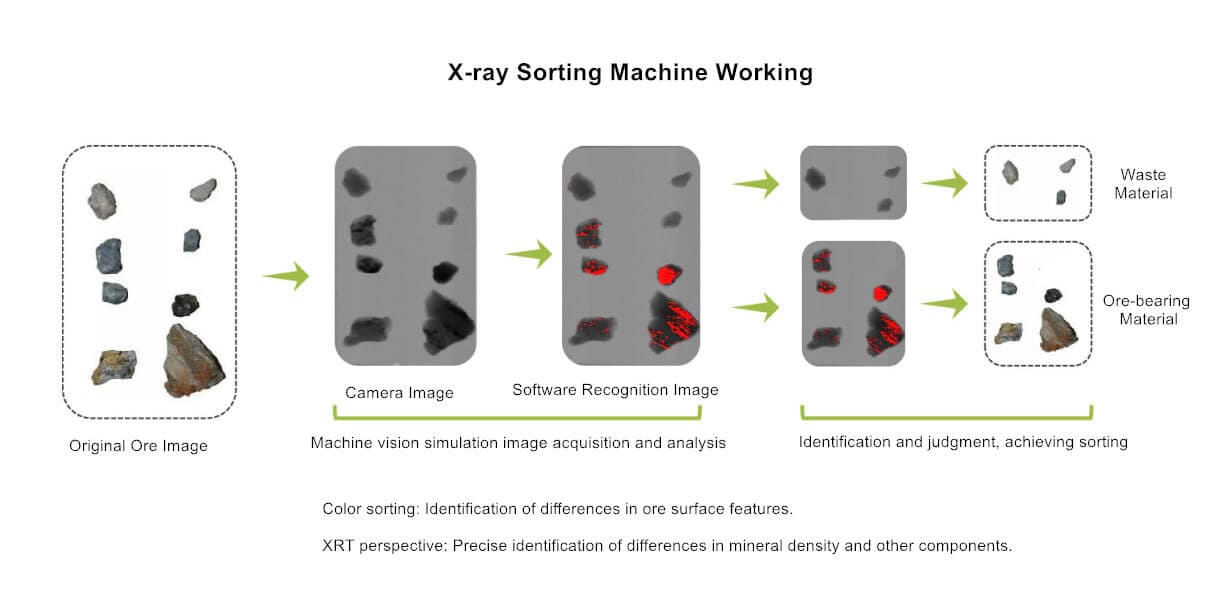

Unveiling the Principle: Nature's Fingerprint Recognition

The secret behind XRT technology lies in diamonds’ unique “molecular ID.” When X-rays penetrate the ore, diamonds produce characteristic fluorescent reactions, much like possessing distinctive biometric features. This atomic-level identification technology penetrates the microscopic world beyond the reach of conventional optical methods, leaving even 0.5mm-diameter diamonds nowhere to hide.

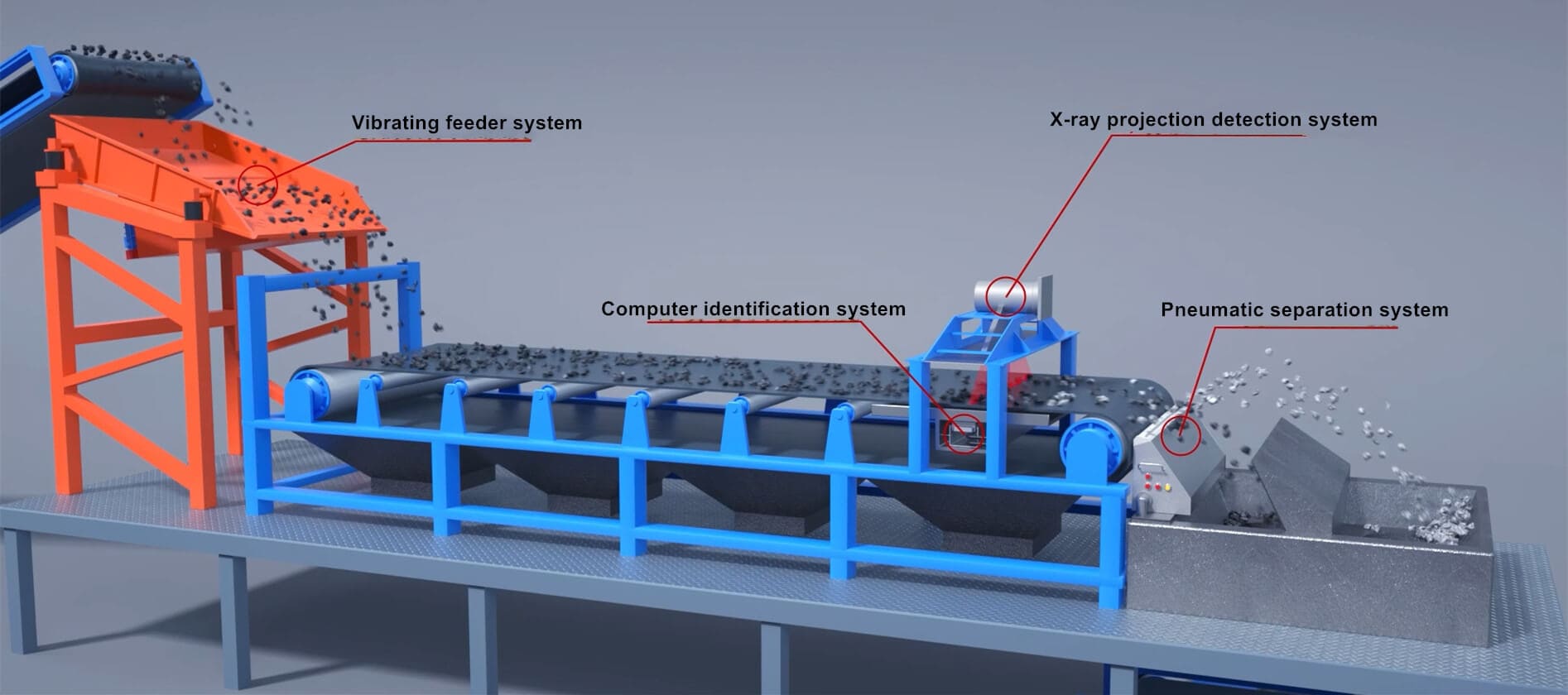

Core System of X-ray Diamond Sorting Machines

The core system of the X-ray diamond sorting machines comprises a vibrating feeder system, a computer recognition system, an X-ray projection detection system, and a pneumatic separation system.

1. Vibratory Feeding System

Function:

- Controls uniform ore feeding to ensure materials pass through the detection zone in a single layer and at a stable speed.

- Eliminates particle stacking to minimize X-ray interference during detection.

Key Components:

- Vibratory Feeder: Adjusts flow rate via electromagnetic vibration.

- Acceleration Belt: Separates clustered particles for accurate detection.

- Flow Diverters: Corrects misaligned ore positions.

Requirements:

- Feed Size: 1–50mm (optimal detection range).

- Moisture Content: <5% (to prevent X-ray scattering).

2. X-ray Transmission Detection System

Function:

- Emits X-rays and measures atomic density absorption differences (Diamond Z=6 vs. Gangue Z=10+).

- Generates high-contrast grayscale images for AI analysis.

Key Components:

- X-ray Tube: 80–160 kV (dual-energy X-rays distinguish synthetic diamonds).

- Detector Array (CdTe/CZT): Captures real-time transmission data.

- Collimator: Focuses the X-ray beam to reduce noise.

Technical Features:

- Resolution down to 0.2mm for tiny diamonds.

- Dual-energy mode filters out silicon carbide (SiC) and other impurities.

3. Computer Identification(AI Processing) System

Function:

- Analyzes X-ray images to identify diamond characteristics (low absorption, homogeneous structure).

- Makes real-time ejection decisions.

Key Components:

- AI Algorithm: Deep learning-based image classification (trained on tens of thousands of diamond samples).

- High-Speed Processor (FPGA/GPU): Processing delay <10ms.

- Database: Stores ore characteristics from different mining regions to optimize sorting accuracy.

Performance Metrics:

- Diamond Recovery Rate: >98%.

- False Ejection Rate: <0.01%.

4. Pneumatic Separation System

Function:

- Precisely ejects diamonds into a collection bin based on AI commands, while waste material continues to the tailings.

Key Components:

- High-Pressure Valve Array: Ejection pressure 300–800 kPa, response time 2–5ms.

- Nozzle Design: Diameter 0.5–2mm to avoid interference with adjacent particles.

Separation Efficiency:

- Single-Particle Positioning Accuracy: ±1mm.

- Throughput Adaptability: 1–300 tons/hour.

Key Benefits of XRT Diamond Sorting Machines

Higher Recovery Rates

Advanced sensors capture tiny diamonds that conventional systems miss, maximizing yield.

Enhanced Productivity

Automated processing allows for faster throughput compared to manual labor.

Reduced Operational Costs

Minimize human error and lower labor expenses with fully automated solutions.

Non-Destructive Sorting

Maintain diamond integrity while efficiently separating them from raw ore.

Why Choose an XRT Diamond Recovery Machine?

Whether you’re in mining, recycling, or industrial diamond processing, investing in diamond sorting equipment powered by X-ray technology ensures:

Eliminate false positives and maximize diamond recovery with precise detection.

Scalability

Handle large volumes effortlessly with high-speed sorting capabilities.

Adaptability

Optimize settings for different diamond types and ore compositions.

Sustainability

Reduce waste and energy consumption compared to older, less efficient methods.

Our cutting-edge XRT diamond recovery systems integrate seamlessly into your plant, using AI-powered X-ray transmission (XRT) technology to detect and separate diamonds with unmatched accuracy—even at microscopic sizes. Whether processing kimberlite, alluvial deposits, or industrial diamond concentrates, our solutions deliver higher recovery rates, reduced waste, and lower energy consumption than traditional methods.

Upgrade Your Diamond Sorting Today

Don’t let outdated technology hold you back—modern XRT diamond recovery machines offer smarter, faster, and more reliable solutions for diamond detection and separation. Whether you’re optimizing an existing facility or setting up a new operation, integrating X-ray diamond sorting machines will revolutionize your workflow and boost profitability.

📩 Contact us today to learn how our cutting-edge diamond sorting equipment can elevate your operations!

Our Diamond Processing Plant Projects

Ready to Optimize Your Diamond Recovery Plant?

Leave your requirements and let our engineers design the mineral processing process and select the most suitable mining equipment for you.