The mainly process of chrome ore processing is gravity separation. Sometimes low intensity magnetic separation or high-intensity magnetic separation will be used to deal with the chrome concentrate for a second processing to improve the grade of the chrome. Also some ores treated by flotation, but the gravity separation is still the main processing way for chrome ores.

Chrome Ore Mining Process

Introduction

About Chrome Ore

Chrome is the most important ore of chromium from which it derives its name. Chromium is an important metal and has a wide range of industrial uses.

Chrome minerals are mainly found in mafic-ultramafic igneous intrusions and are also sometimes found in metamorphic rocks. The Chrome minerals occur in layered formations that can be hundreds of kilometers long and a few meters thick. Chrome is also common in iron meteorites and forms in association with silicates and troilite minerals.

Gravity separation is the main process for chrome processing, sometimes to improve the grade of the chrome, the chrome concentrate will be separated by lo- intensity magnetic separation or high-intensity magnetic separation for second processing. Several ores can use the flotation or flocculation flotation process.

Mineral Processing

Chrome Ore Processing

For chrome processing, there are gravity separation, flotation, magnetic separation, and other methods. We can obtain the mineral’s analysis report and test report to finally decide the proper solution.

Chrome gravity separation

The gravity separation and magnetic separation processes are the main chrome extraction and beneficiation methods. Chrome ore gravity mining equipment has a jig separator, shaking table, spiral classifier, centrifugal concentrator, and spiral chute. Sometimes, use a weak magnetic separator or a high-intensity magnetic separator to further improve the grade of chromium concentrate and the ratio of chromium to iron. Besides, some chrome mines use the flotation and flocculation methods.

Chrome magnetic separation

Determining the chrome ore concentrating method and selecting the right chrome mining equipment is closely related to the physical and chemical properties of chromium ore. Because chromite is weakly magnetic, with the development of high-intensity magnetic separation technology, the technology of purifying chromium ore with high-intensity magnetic separation has been very mature. Moreover, the magnetic separation process has no pollution to the environment, the chrome ore magnetic separation technology has been popularized and applied in the major mineral processing plants.

Usually, the chrome ore is processed through gravity separation, and after the screening, the slurry is sent to a flotation cell or magnetic separator. The concentrates are dewatered after flotation.

Rock Chrome Process Plant

The raw ore should be crushed by a jaw crusher initially. When it gets a reasonable fineness, it is transported into a vibrating screen through a conveyor and feeder.

The screened ores get the next procedure: milling process in the ball mill, then next jigging separation. The milled ore gets into a chrome jig separator for gravity separation.

Chrome ore is processed by crushing–screening–washing–selection or heavy medium separation for block granularity enrichment. Flowsheet of medium separation–jigging–milling–spiral beneficiation–intensity magnetic separation has been adopted widely, and flow sheet of shaking table–ore washing–dry normal magnetic separation–intensity magnetic separation–floatation separation is used to separate sea chrome sand.

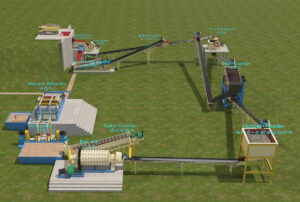

JXSC – Rock Chrome Ore Processing Plant Design

Plant Overview

This setup is engineered for processing rock chrome ore, integrating stages from raw material feeding to high-grade concentrate production.

The system includes:

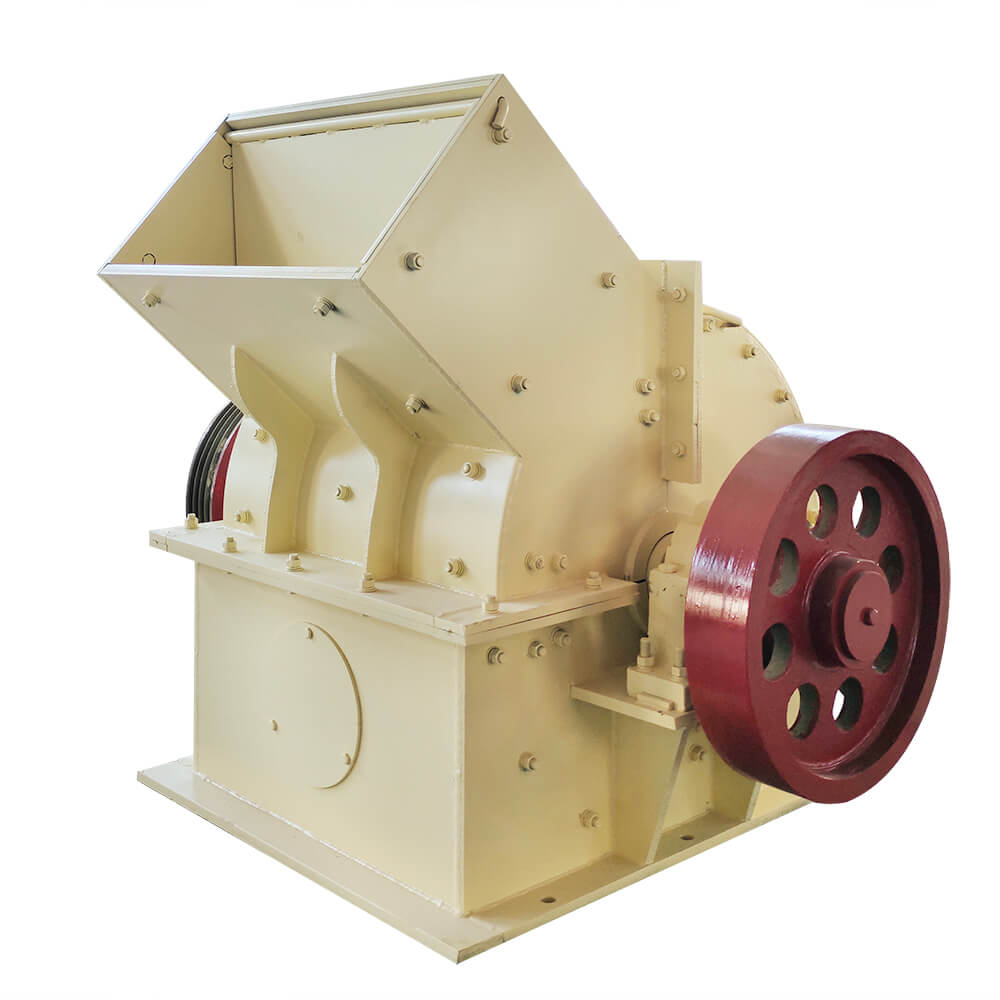

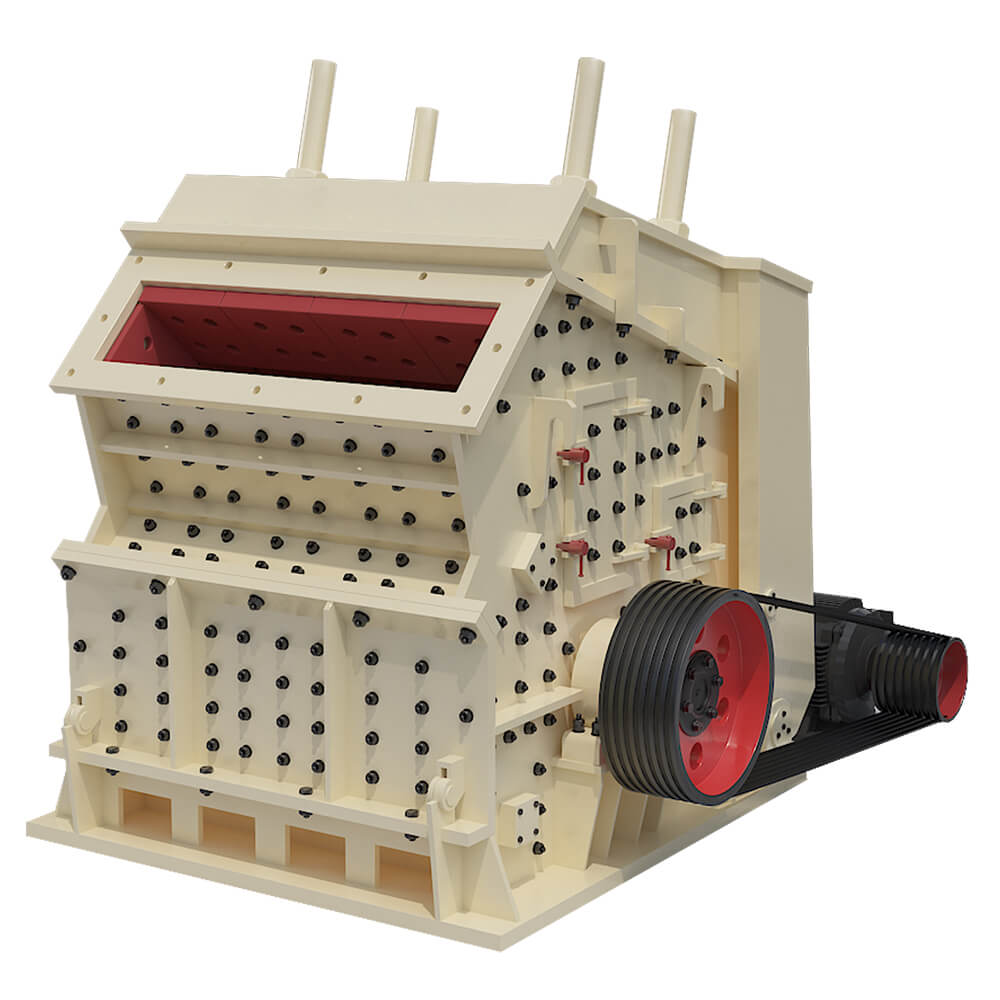

- Crushing Circuit (Primary + Fine Crushing)

- Screening & Storage

- Ball Mill Grinding (Closed-circuit with Spiral Classifier)

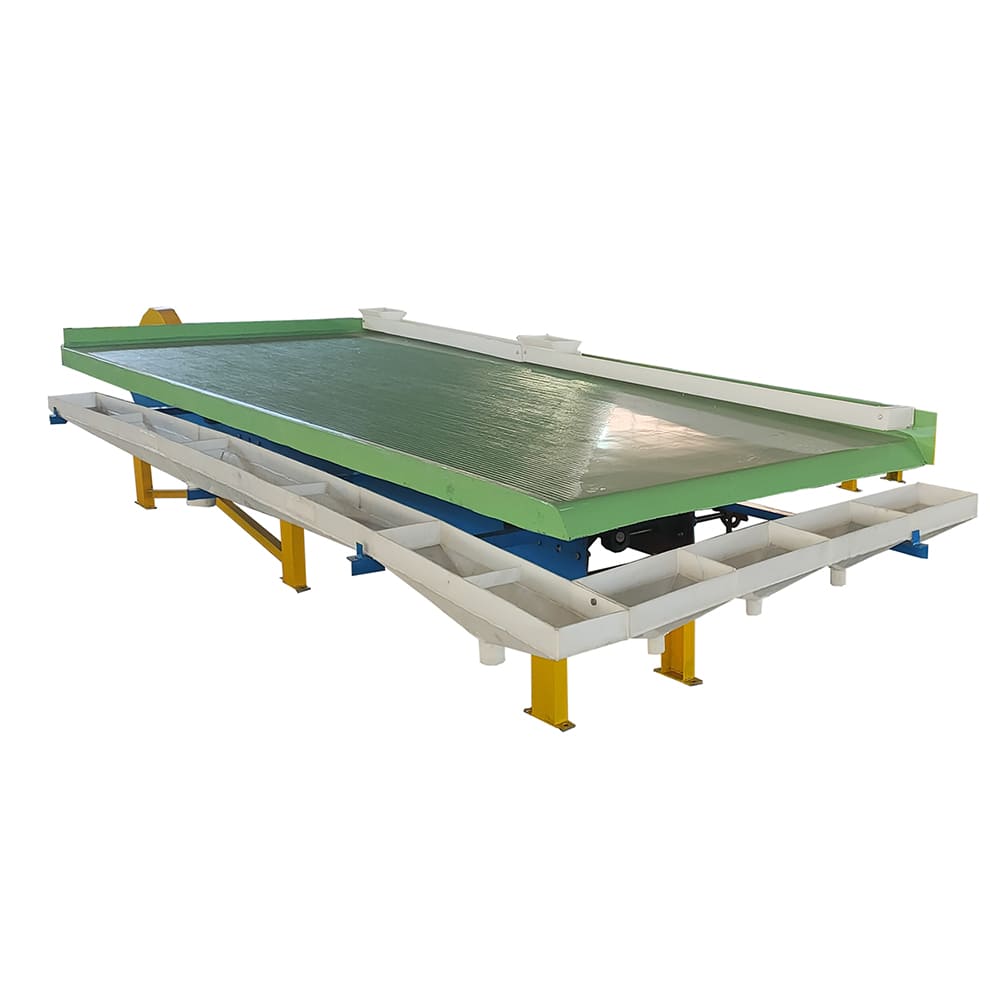

- Gravity Separation (Dual-stage Spiral Chutes + Shaking Tables)

- Optional Magnetic Separation (For Ultra-high-grade Concentrate)

Typical Results:

- Concentrate Grade: 48-52% Cr₂O₃

- Tailings Grade: <8% Cr₂O₃ (Recovery-driven design)

Technical Advantages

- Optimized Crushing: Grizzly feeder minimizes jaw crusher workload.

- Energy Milling: Closed-circuit ball milling reduces overgrinding.

- Maximized Recovery: Dual-stage spirals + shaking tables ensure >92% recovery.

- Flexible Scaling: Compact layout suits small mines | Expandable for large operations.

For tailored solutions, provide:

- Ore XRD/TGA Analysis

- Target Capacity & Grade Requirements

- Site Constraints (Power/Water/Space)

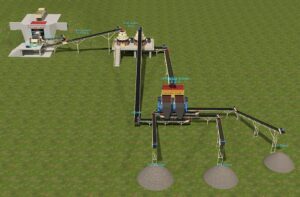

Alluvial Chrome Process Plant

Alluvial chrome process flow

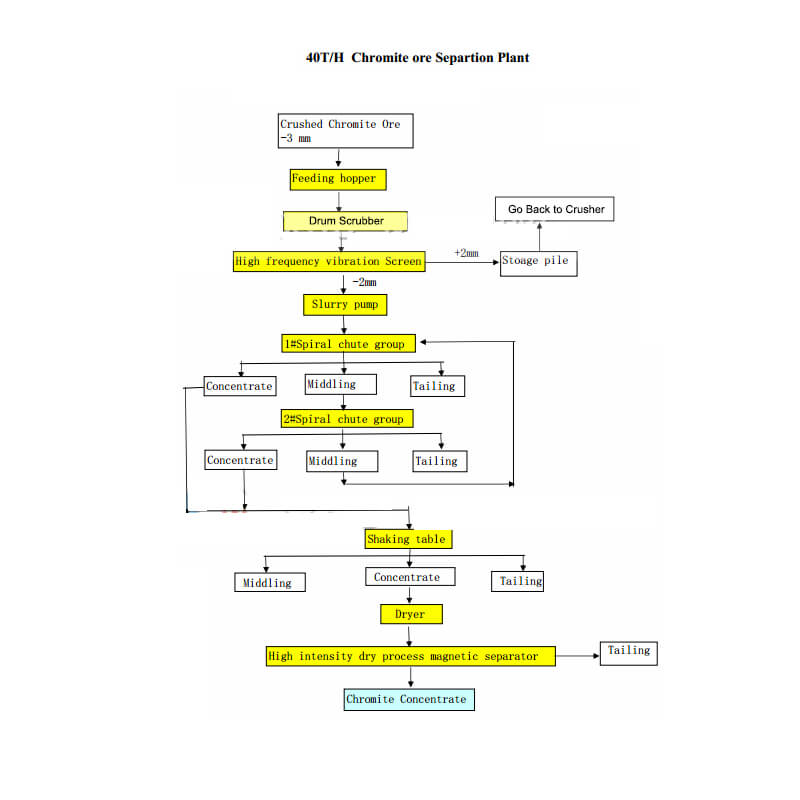

Feeding -> washing -> sieving -> primary gravity separation -> 2nd stage gravity concentration -> magnetic separation for upgrading.

Chrome ore Feeding: This can be a vibration feeding machine, a feeding hopper, a belt feeder, a wheel loader, or an excavator that feeds directly. Usually will add a grizzly bar on the vibration feeder or hopper to remove big waste stones first. It depends on the processing capacity to choose suitable chrome ore mining equipment.

Chrome ore Washing: The chrome ore washing machine is for washing to clean the clay and mud in the raw material. The most popular used are chrome ore washing trommel scrubber and chrome ore washing trommel screen. Chrome ore trommel scrubber washer is for washing chrome ore raw material that with much sticky clay, chromite ore washing trommel screen is for washing chromite ore raw material that does not have much sticky clay. It depends on raw material conditions to choose suitable chrome ore washing equipment.

Chrome ore Sieving: After washing, sieve out some bigger waste stones, and the under-screen slurry will go to the next separation machine. This sieving process can use a trommel screen, or vibration screen, or a chrome ore high-frequency vibration screen, which is widely used in chrome ore mining equipment.

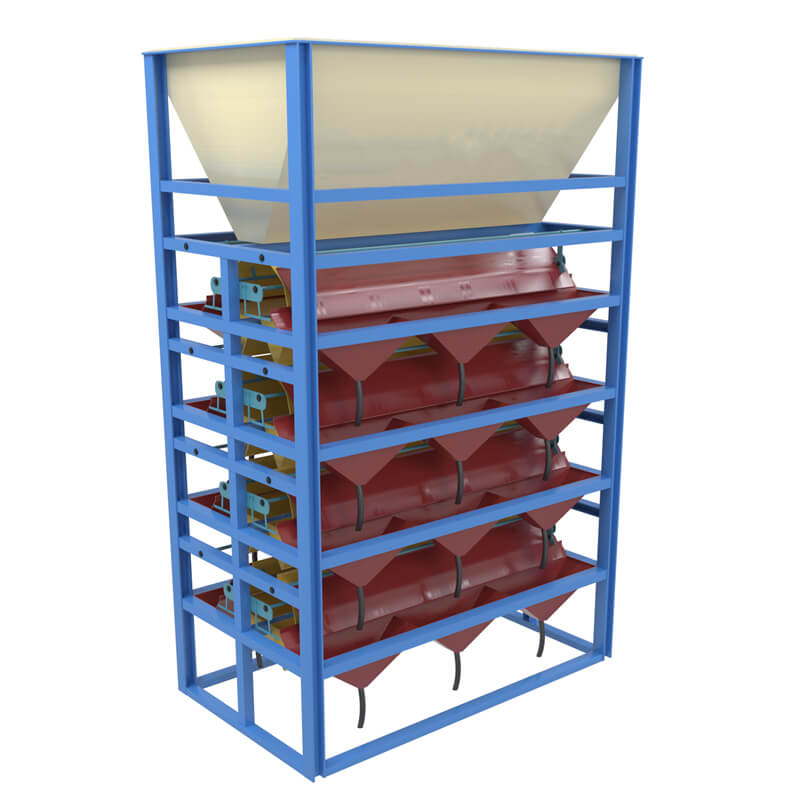

Chrome ore Primary Gravity Separation: It is for the primary chrome ore concentration process, jig separator or spiral chute separator are the best choices of chrome ore gravity mining equipment. The concentrated ore discharged from them will be sent to the 2nd stage concentration machine.

2nd Stage Concentration Process: The concentrated ore from the chrome ore jig machine or spiral chute separator will go to the chrome ore shaking table concentration machine for final concentration, which can get high-grade chrome ore concentrate. The shaking table is a good concentration effect mining equipment for the chrome ore processing plant.

Chromite Ore Refining: If you need a much higher chrome ore grade, you can use a high-intensity magnetic separator to upgrade it. The chrome ore magnetic separator is also an important chrome ore mining equipment for final upgrading.

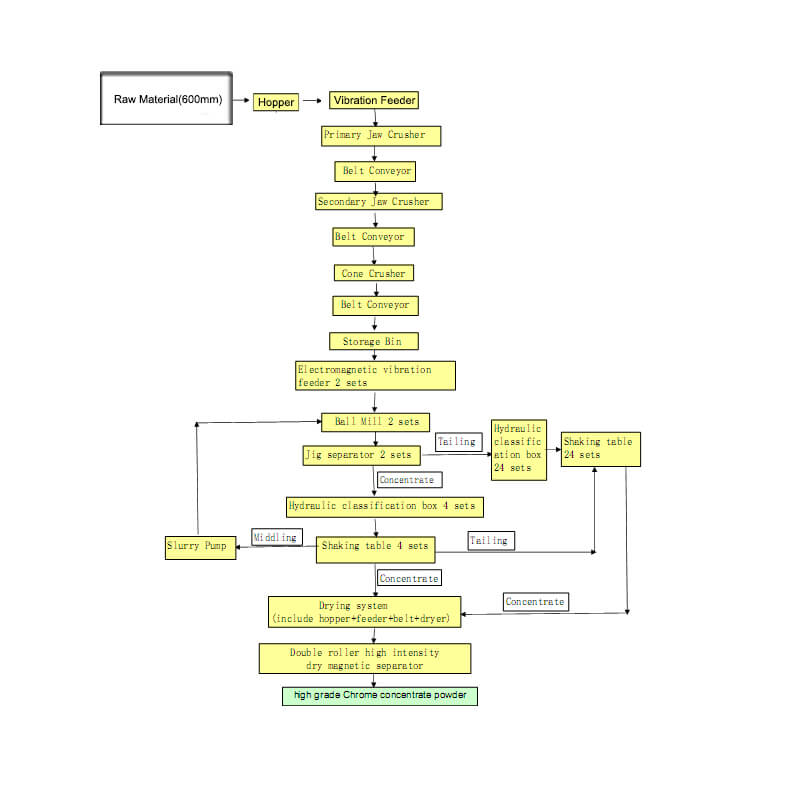

JXSC – 100 TPH Complete Alluvial Chrome Ore Processing Plant Design

Ore Information & Customer Requirements

- Ore Type: Alluvial chrome ore

- Mine Characteristics: Contains abundant clay and soil, mixed with rocks, gravel, and plant debris

- Concentrate Size: <2mm

- Raw Ore Composition: -2mm material accounts for 40-50%

- Feed Grade: Cr₂O₃ content 17-23%

- Target Grade: Upgrade Cr₂O₃ to 48-50% after beneficiation

- Production Requirement: Single 100 TPH plant, daily output 500 tons (20-hour operation)

- Iron Removal: Reduce magnetite content to improve the Cr/Fe ratio

Process Flow Breakdown

Raw Material Pre-Treatment → Spiral Separation System → Magnetic Separation → Shaking Table Refinement → Dewatering System

Design Highlights

- Efficient Scrubbing: Trommel + dual screening ensures effective clay removal

- Multi-Stage Recovery: Spirals + shaking tables achieve >90% recovery

- Grade Control: Magnetic separation + shaking tables guarantee the Cr/Fe ratio

- Water Recycling: Closed-loop system minimizes water consumption

Key Equipment List: vibrating feeder, trommel scrubber, spiral separators, magnetic separator, shaking table, slurry pump, belt conveyors.