Diamond Washing Plant

Custom-Engineered Solutions for Alluvial & Hard Rock Diamonds,

Backed by 40+ Years of Mining Expertise

💎 Maximize Diamond Recovery Rates & Purity

Boost Your Diamond Yields with Advanced Washing Plants

– Custom Solutions for Alluvial & Hard Rock

Unlock Higher Diamond Yields with Advanced Washing Technology

In diamond mining, every carat counts—but inconsistent recovery rates and impurity challenges can cripple profitability. JXSC’s cutting-edge diamond washing plants are engineered to maximize diamond recovery and purity, whether you’re processing alluvial deposits or hard rock sources. Our modular, heavy-duty scrubbers and precision gravity separators remove clay, gravel, and gangue with minimal diamond loss. Unlike outdated trommel-only setups, our custom-configured circuits optimize water use, throughput, and final concentrate grade—delivering diamonds ready for sorting with fewer processing stages.

Trusted by Industry Leaders—Proven Over 4 Decades

With 40+ years of mining expertise, JXSC designs diamond recovery solutions tailored to your ore’s unique characteristics—from particle size distribution to clay content. Our plants feature high-pressure washing scrubbers, X-ray sorters, and DMS cyclones to handle even ultra-fine diamonds trapped in sticky conglomerates. Whether scaling up artisanal operations or streamlining large-scale production, we deliver turnkey systems with 95%+ recovery rates, backed by field-tested durability in Africa, South America, and beyond. Lower your operational risk and boost ROI with technology refined through decades of real-world success.

Your Diamond Washing Problems & Our Diamond Processing Solutions

Bullet Points

- Low diamond recovery rates due to outdated equipment.

- High operating costs from inefficient processing.

- Difficulty handling clay-rich or gravel-heavy ore.

JXSC's Modular Diamond Washing Plants

- Higher Recovery: Advanced scrubbing & screening (up to 98% efficiency).

- Lower Costs: Energy-efficient designs with reduced water usage.

- Custom Flows: Tailored for alluvial/gravel/clay deposits.

Don’t Let Outdated Equipment Hold Back Your Profits!

Whether you’re battling low recovery rates, soaring costs, or tricky ore types, JXSC’s cutting-edge diamond washing plants deliver the efficiency and customization your operation needs. Stop settling for lost diamonds and wasted resources—our modular solutions ensure you extract more, spend less, and conquer every mining challenge.

Contact JXSC Now for Your Custom Diamond Solution

— Maximize Recovery & Profitability Today!

Core Technologies and Equipment for Diamond Processing

To achieve 98% recovery rates and tackle tough clay/gravel deposits, JXSC integrates proven technologies into every modular washing plant:

Proven Diamond Processing Systems

Key Technologies

♥ Advanced Scrubbing Systems

Breaks down cemented clays without damaging diamonds.

♥ Multi-Stage Vibrating Screens

Precision classification for optimal size separation.

♥ Dense Media Separation (DMS)

Enhances diamond recovery from complex ores.

♥ X-Ray Fluorescence (XRF) Sorters

Final-stage AI-powered diamond detection.

Essential Equipment

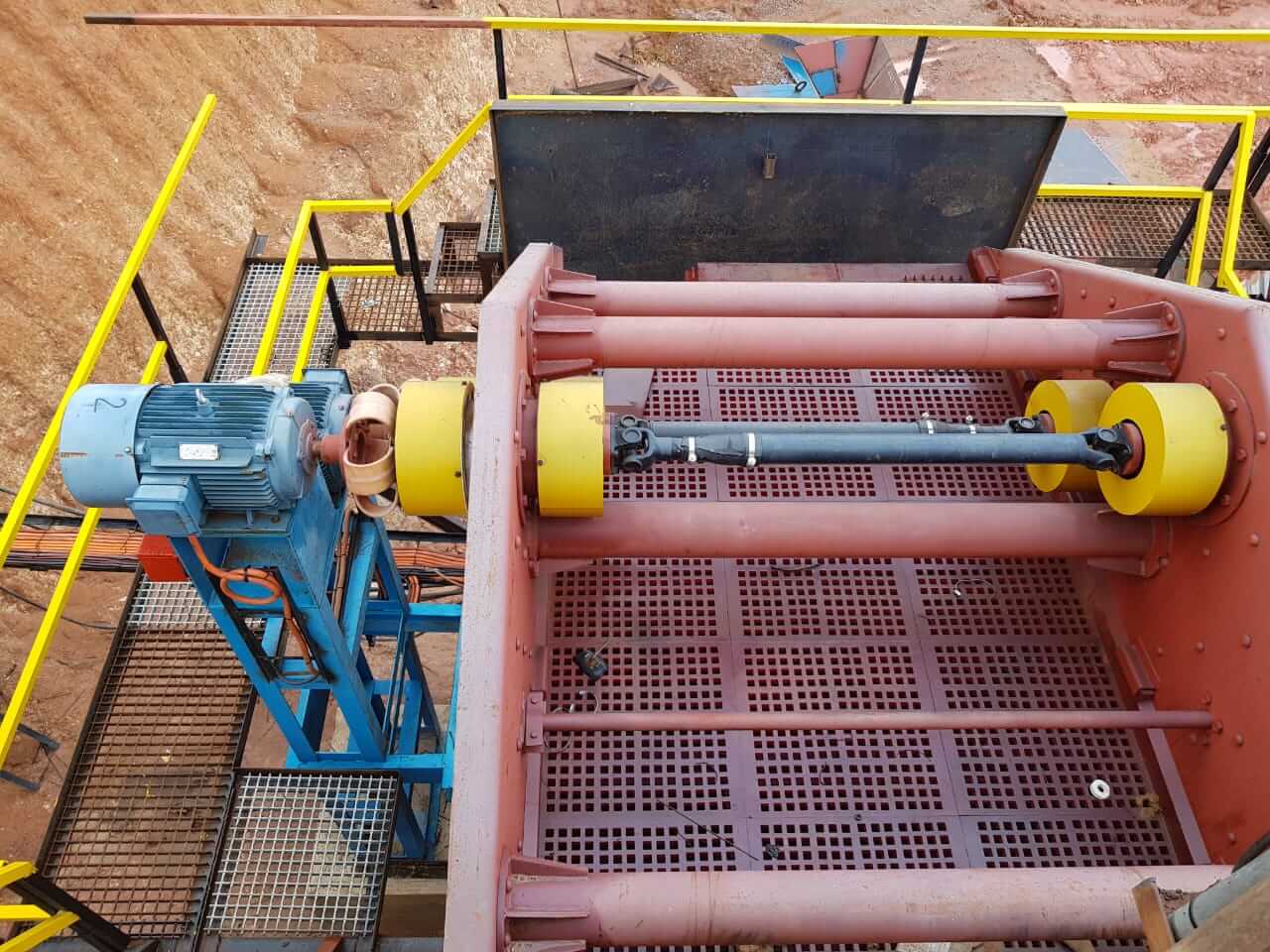

Diamond washing plants rely on specialized machinery to efficiently extract diamonds from alluvial deposits. The specialized machinery includes: Vibrating Grizzly Feeder or Hopper, Rotary Scrubber, Vibrating Screens, log washers, Dense Media Separator (DMS), Jig Machine, Spiral Concentrator, X-Ray Separator, Magnetic Separator, Slurry Pump, Diamond Sorting Machine, etc. Here’s a breakdown of the key equipment used:

Rotary Scrubber

Clay breakdown & ore washing

Cyclone Separation Units

High-purity diamond separation

Jig Concentrators

Works via pulsating water flow to recover heavy minerals like diamonds.

Vibrating Screen

Size classification (e.g., 0-5mm, 5-20mm)

X-Ray Sorter

Final diamond extraction (optional)

Dewatering Screens & Tailings Management

Filters and reuses water to minimize environmental impact.

For efficient diamond recovery, equipment selection depends on deposit type (alluvial, rock, or mixed ores), capacity needs, and budget. Proper setup maximizes both recovery rate and operational efficiency. We are specifically engineered to tackle Africa’s most demanding mining environments—from alluvial deposits in Angola to kimberlite pipe mining areas in Botswana.

- Ready to Upgrade Your Diamond Recovery?

Don’t settle for outdated technology or guesswork—partner with JXSC’s engineered-for-performance washing systems today!

To learn how our cutting-edge diamond washing equipment can elevate your operations!

JXSC Diamond Washing Plant Solution

Alluvial Diamond Process

Capacity: 200 TPH

Raw Ore: Alluvial diamond with much sticky material; The material size range is 0-300mm.

Process: Hopper+vibrating feeder(with grizzly bar) → trommel scrubber → high-frequency vibration screen 1# → Hopper+vibration feeder → high-frequency vibration screen 2# →jig separator → dewatering screen

200 TPH Alluvial Diamond Washing Explanation

- The Hopper + vibration feeder (with grizzly bar) for sieving 0-130mm to the trommel scrubber and 130-300mm to the waste pile.

- The trommel scrubber is for washing the size 0-130mm, screening the size 0-25mm to the high-frequency vibration screen 1#, 25-130mm to the waste pile.

- The high-frequency vibration screen 1# is for sieving the size 0-0.5mm to the slurry pool, 0.5-25mm to the hopper.

- The hopper + vibration feeder is for feeding the materials to the high-frequency vibration screen 2# more smoothly.

- The high-frequency vibration screen 2# is for sieving different materials sizes to different jig separators, ensuring the high efficiency of the jig separator.

- The jig separator is for concentrating the diamond, and the dewatering screen is for dewatering the products from the jig separator.

Alluvial & Rock Diamond Process

Capacity: 50 TPH

Raw Ore: Alluvial Diamond & Kimberlite Diamond Mixture Material

Process: Feeding, washing, crushing, screening, and diamond jig separation.

Features:

- This plant will recover free diamonds and diamonds in the rock by the jig separator.

- Low investment has easy operation and installation, a simple flowchart, good recovery effect.

50 TPH Alluvial Diamond & Kimberlite Diamond Plant Explanation

- Raw material feed to the vibration feeder, the feeder is equipped with a grizzly bar to remove the big stone and can break down the smaller alluvial raw material roughly by spraying high-pressure water, feed material smoothly to the trommel scrubber. The oversized stone will be sent to the crushing plant’s storage bin.

- Trommel scrubber is for washing and cleaning the sticky clay, with 2 layers of PU screen, screen out +25mm sending to crushing plant, 0-25mm goes to high-frequency vibration screen.

- Vibration screen is a high-frequency type, with a 25mm & 1mm 2 desk PU screen, for removing the 0-1mm waste slurry, and screening out 1-25mm that contains a diamond.

- The crushing plant is for crushing kimberlite diamond to below 25mm. It has with primary jaw crusher to crush big rocks to a smaller size, then use a fine jaw crusher to crush below 25mm, output from the fine jaw crusher goes to this vibration screen to screen out +25 mm send back to crush again.

- All 1-25mm from the vibration screen will go to the jig separator by belt conveyor, and distributed to several sets of jig separators to get diamond concentrate ore. If you want a higher purity diamond, the concentrate ore can go to the X-RAY sorter machine to select out diamonds.

| Competitors | JXSC |

| Generic designs | Custom flows per ore geology |

| Limited support | 24/7 multilingual engineers |

| Hidden fees | Fixed-price EPC contracts |

- Need Custom Diamond Tech?

Our engineers tailor solutions for your exact ore type.

Our Diamond Processing Plant Case Study

Ready to Optimize Your Diamond Recovery Plant?

Leave your requirements and let our engineers design the mineral processing process and select the most suitable mining equipment for you.