Gold Flotation Solution

Flotation process is commonly used in dealing with highly floatable sulfide minerals containing gold ore, and it’s widely used to process the rock gold. The gold flotation process cost low and can maximum enrich gold to the sulfide mineral.

Gold Flotation Process

Introduction

About Gold Ore

Gold ore is a mineral aggregate with sufficient gold content and can be used industrially. Gold mines are places where gold is obtained through mining operations According to the structural state and the content of gold in the ore, the gold deposit is a kind of industrial deposit which is formed by Mineralization The gold minerals in gold deposits can be divided into three categories: Gold minerals, gold-bearing Minerals, and gold-bearing minerals. The so-called independent mineral of gold refers to the gold in the form of gold minerals and gold-bearing minerals.

Mineral Processing

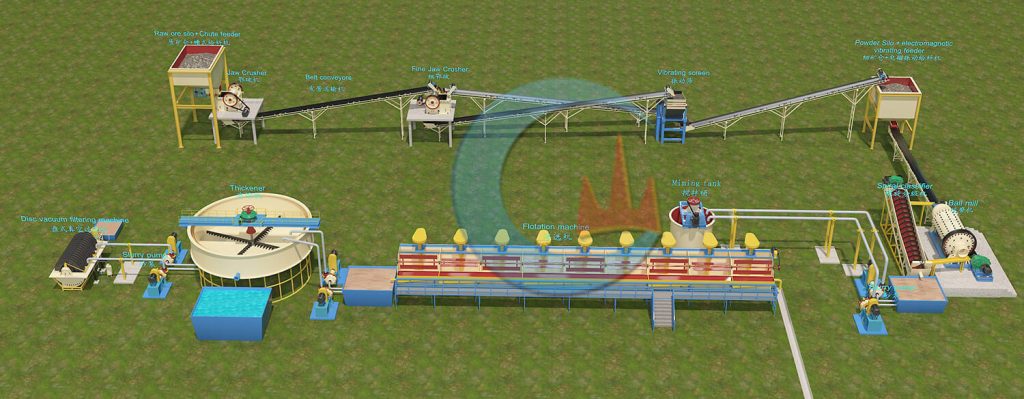

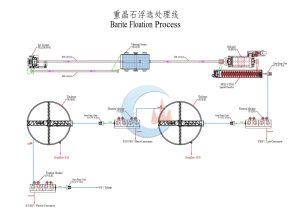

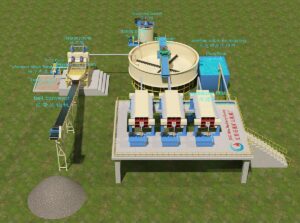

Gold Flotation Process

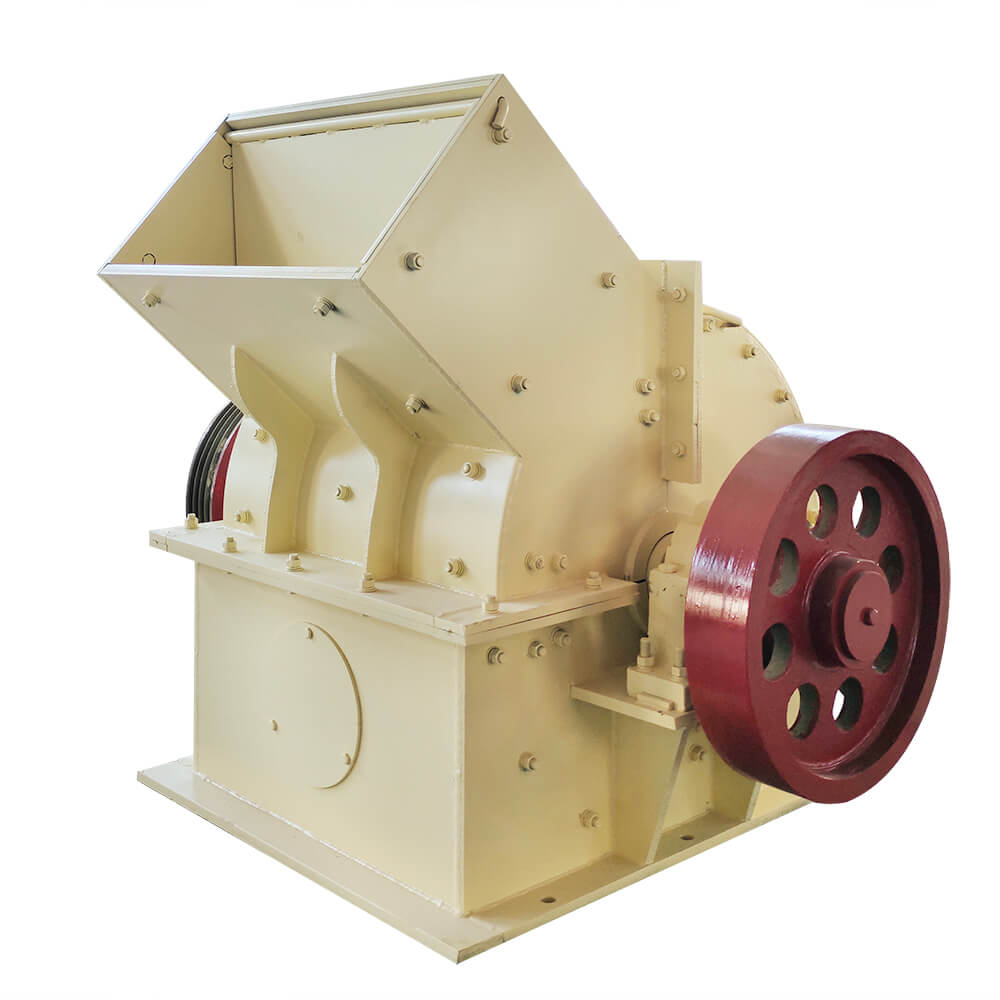

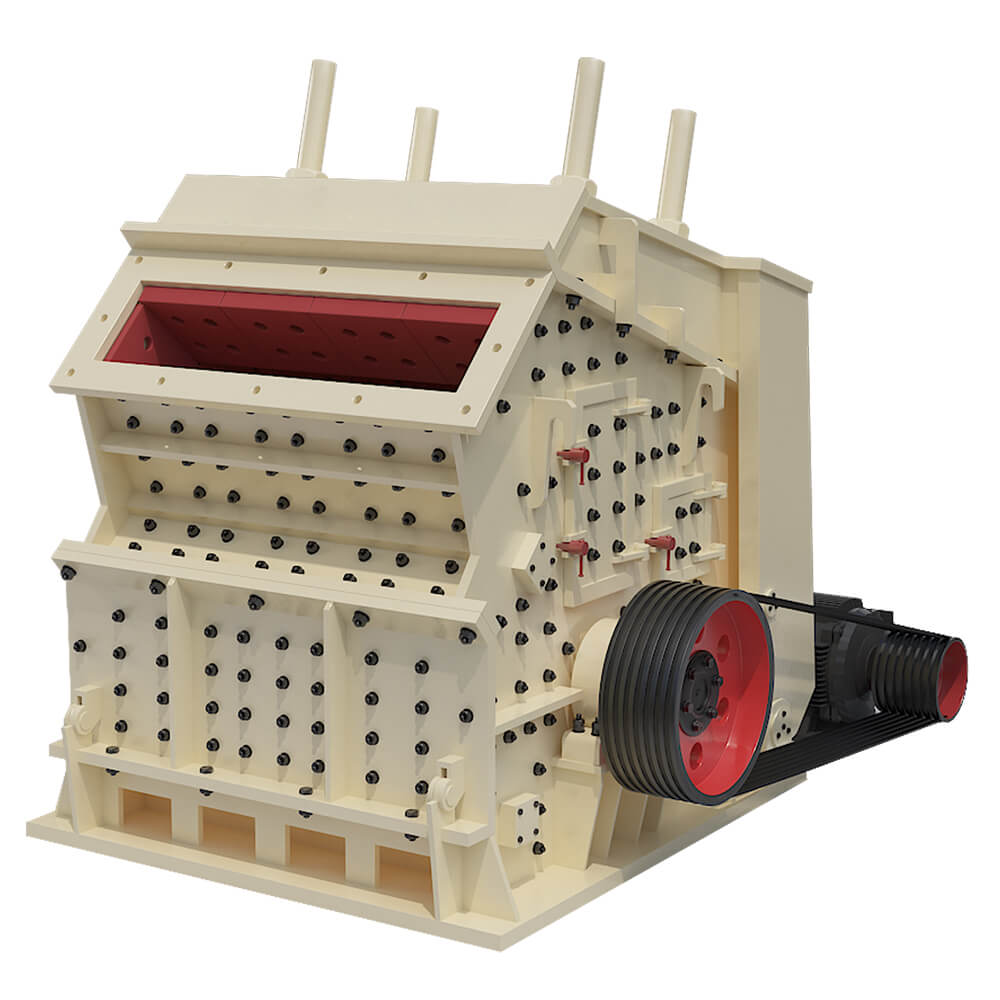

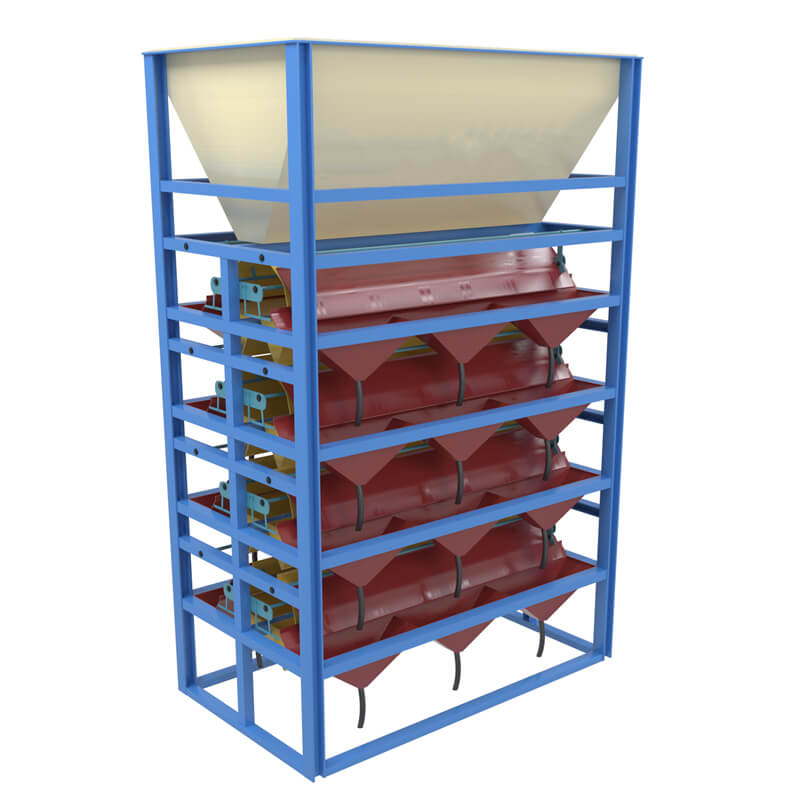

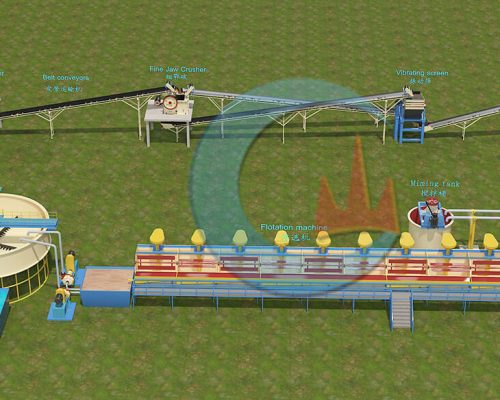

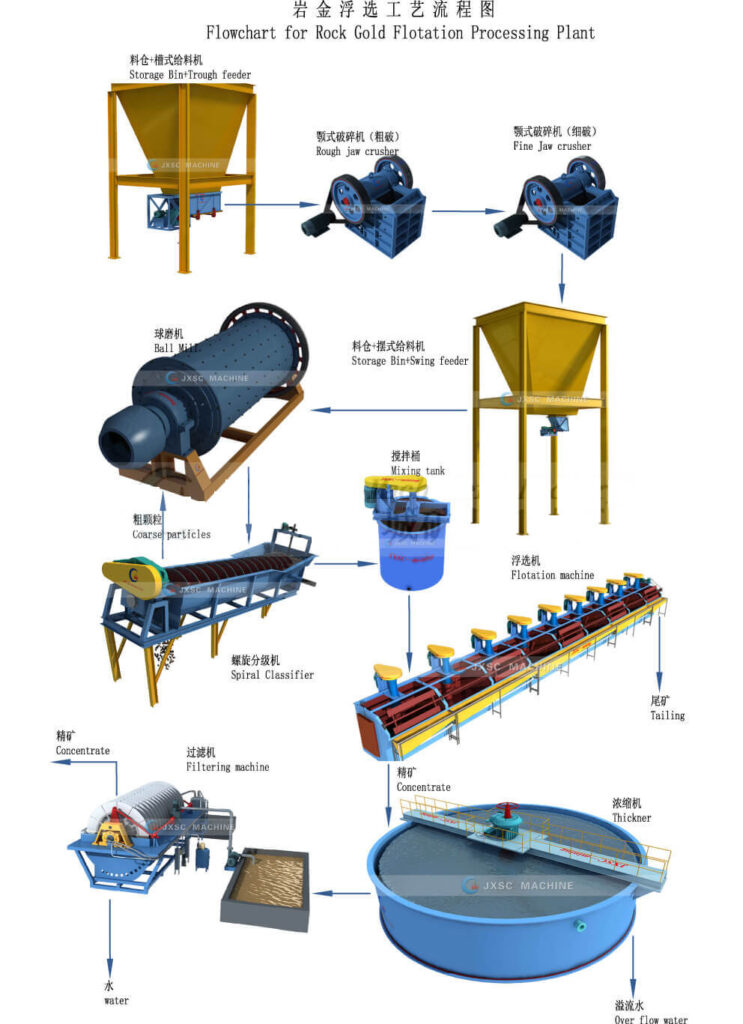

1. Crushing System

The rock gold is fed to the rough jaw crusher by a trough feeder to be crushed. Then, it is delivered to the fine jaw crusher for secondary crushing.

2. Grinding System

After the crushing, the gold ore is sent to the ball mill to be ground. The output material of the ball mill(<1mm) goes to the spiral classifier for grading. The 200 mesh slurry can go to the next flotation system, and the larger ones return to the ball mill.

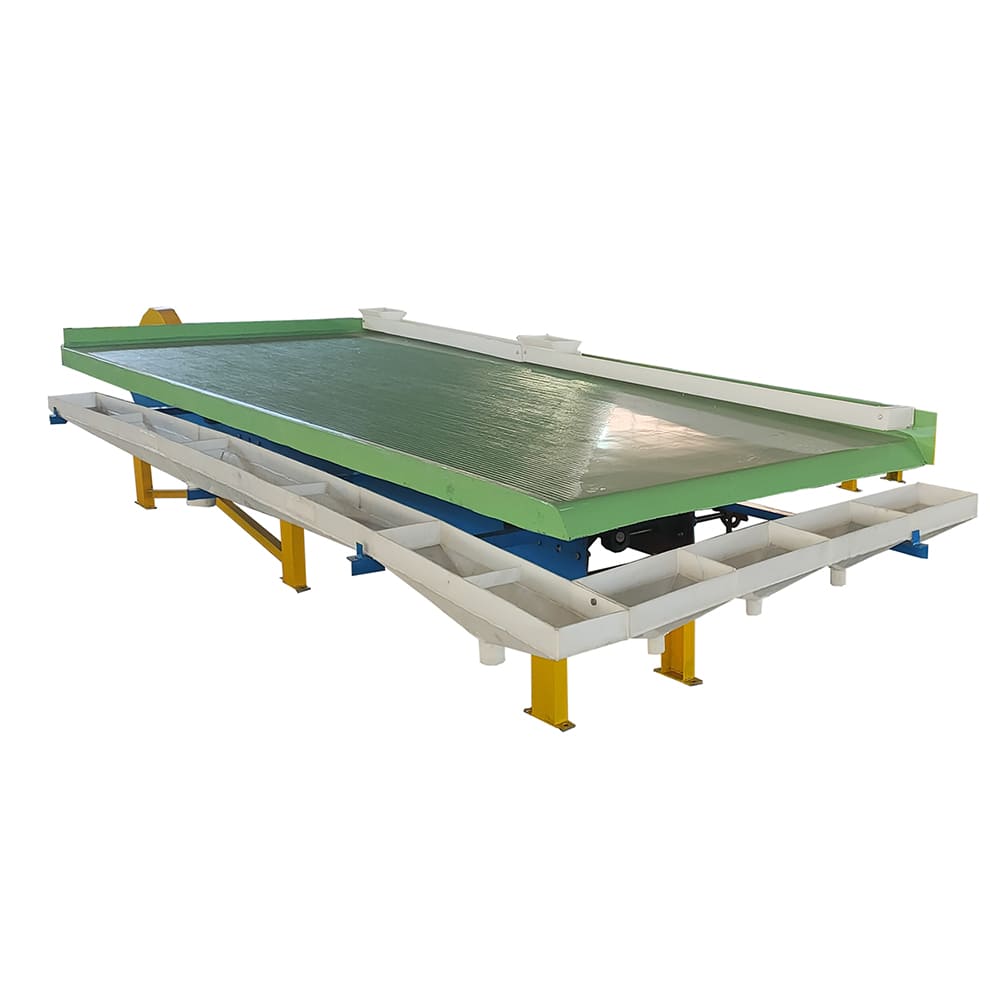

3. Flotation System

The 200 mesh slurry will be firstly sent to the mixing tank by slurry pump, to make sure material is mixed completely, then from mixing tank go to flotation machines, need to add different chemicals in flotation machine to separate different minerals, the flotation process has the primary selection, secondary selection, and final selection, this is for increase minerals grade to maximum after the process. If you need a higher grade, then you need to flotation more times. Will get each mineral concentrate ore after the flotation system.

4. Concentrate Ore Filtering System

After getting the minerals to concentrate ore from the flotation system, use the thickener to concentrate, make higher density, then send to the disc vacuum filter machine to filter water, and get more dry concentrate minerals. Then it can be dried in the sun or by a drying machine to get completely dry minerals to concentrate ore.