Limonite Beneficiation Process

Limonite (Fe₂O₃·nH₂O) is a hydrous iron oxide ore with 35-55% Fe, often containing clay and impurities. Key beneficiation methods include gravity separation, magnetic separation, flotation, magnetization roasting-magnetic separation, gravity-magnetic separation, and flotation-strong magnetic separation.

Limonite Ore Beneficiation

Introduction

About Limonite Ore

Limonite ore is a secondary iron ore composed mainly of hydrated iron oxide minerals, typically a mixture of goethite (α-FeO(OH)) and lepidocrocite (γ-FeO(OH)), along with clay, silica, and other impurities. It forms through the weathering and oxidation of primary iron minerals like magnetite (Fe₃O₄) and pyrite (FeS₂).

Key Characteristics

Chemical Composition

- General formula: FeO(OH)·nH₂O

- Iron content: 35–60% (lower than hematite or magnetite).

- Contains impurities (clay, phosphorus, sulfur, manganese).

Physical Properties

- Color: Yellowish-brown to dark brown (gives “rusty” appearance).

- Texture: Earthy, porous, sometimes botryoidal (bubble-like) or stalactitic.

- Streak: Yellowish-brown.

- Hardness: 4–5.5 on Mohs scale (softer than hematite).

Formation

Formed through chemical weathering (oxidation & hydration) of iron-rich minerals in wet environments.

From Pyrite: Pyrite (FeS₂) + Oxygen + Water → Limonite + Sulfuric Acid

From Magnetite/Hematite: Dissolution & reprecipitation forms iron hydroxides.

Commonly found in swamps, bogs, tropical soils (laterite), and iron-rich sedimentary rocks.

Mineral Processing

Limonite Beneficiation Methods

The primary beneficiation methods for limonite include single gravity separation, single magnetic separation, single flotation, magnetization roasting-magnetic separation process, flotation-strong magnetic separation process, and gravity-strong magnetic separation process. The specific process must be selected based on the mineral characteristics.

Single Gravity Separation

Used for: Coarse particles (>0.5 mm) Limonite ore with significant density differences.

Techniques: Separates iron ore from gangue using density differences via equipment such as shaking tables and jigs. Coarse-grained material is suitable for jig separators, while fine-grained material is recommended for spiral chutes(concentrators) or shaking tables.

Advantages: Low cost, simple operation and maintenance, low power consumption, and no need to consume chemicals.

Limitations: Struggles with ultrafines (<0.038mm)

Single Magnetic Separation

Used for: Weakly magnetic limonite or roasted magnetite (Fe₃O₄); Medium-grade ore (35–45% Fe) is directly separated.

Techniques: Separate magnetic minerals (such as magnetite-bearing limonite) from non-magnetic gangue using strong magnetic fields. High-Intensity Magnetic Separator (1.0~2.0 T) separates weakly magnetic limonite (particle size 0.5~0.03 mm). High-Gradient Magnetic Separator (HGMS) processes fine-grained (<0.03 mm) mineral slime.

Advantages: Simple process, convenient management, and strong adaptability.

Limitations: Less effective for fine-grained (-20μm) tailings. Non-magnetic impurities (Al₂O₃, SiO₂) are difficult to remove.

Single Flotation

Used for: Fine-grained inclusions (<0.074 mm) or limonite containing harmful impurities such as high phosphorus, sulfur, or aluminosilicates.

Chemical Regime:

- Collectors: Fatty acids (e.g., oleic acid) or sulfonates (e.g., sodium petroleum sulfonate).

- Inhibitors: Sodium silicate (inhibits quartz), starch (inhibits clay).

- pH Adjustment: Slightly alkaline (pH=8–9).

Advantages: Effectively removes phosphorus (P < 0.1%) and reduces silica (SiO₂ < 8%). Adaptable to complex ores, Such as high-alumina limonite (Al₂O₃ > 5%).

Limitations: High cost, difficult wastewater treatment.

Magnetization Roasting-Magnetic Separation Process

Used for: Ores containing non-magnetic gangue, it can enhance the grade of the concentrate.

Techniques: This process primarily involves magnetic roasting and weak magnetic separation. Reductive roasting (700–900°C): Limonite → Magnetite. Weak magnetic separation (0.3–0.5 T): Separation of roasted products.

Advantages: Can increase the iron grade of the concentrate to over 60%.

Limitations: Greater energy consumption and increased costs

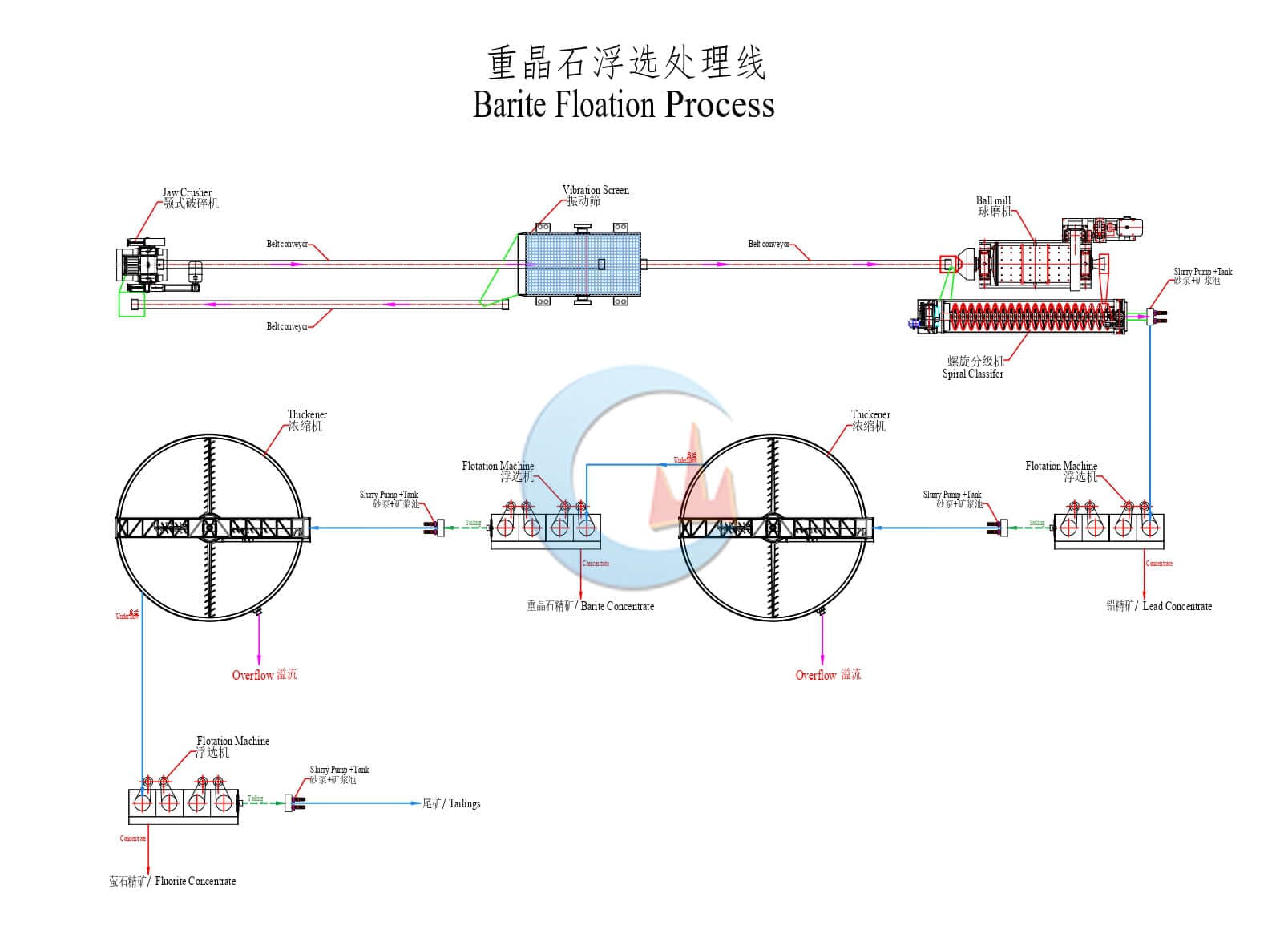

Flotation-Strong Magnetic Separation Processes

Used for: Fine-grained (<0.074 mm) limonite.

Techniques: After recovering fine-grained minerals via flotation, secondary purification is achieved through high-intensity magnetic separation (10,000-20,000 Gs).

Advantages: Improved recovery rates and concentrate quality, expanded particle size recovery range.

Limitations: The process is complex and requires optimization of the reagent-magnetic separation parameter matching. The overall cost is high (dual energy consumption from flotation and magnetic separation).

Gravity-Strong Magnetic Separation Processes

Used for: A composite ore consisting of coarse and fine particles.

Techniques: Coarse-grained minerals are first processed by gravity separation, followed by strong magnetic separation to recover iron minerals from fine particles and tailings.

Advantages: 75%-85% comprehensive recovery rate

Limitations: Requires multi-stage pre-treatment with a relatively lengthy process. Recovery rates for fine-grained fractions remain limited (~75%).

Rock Limonite Ore Processing Plant

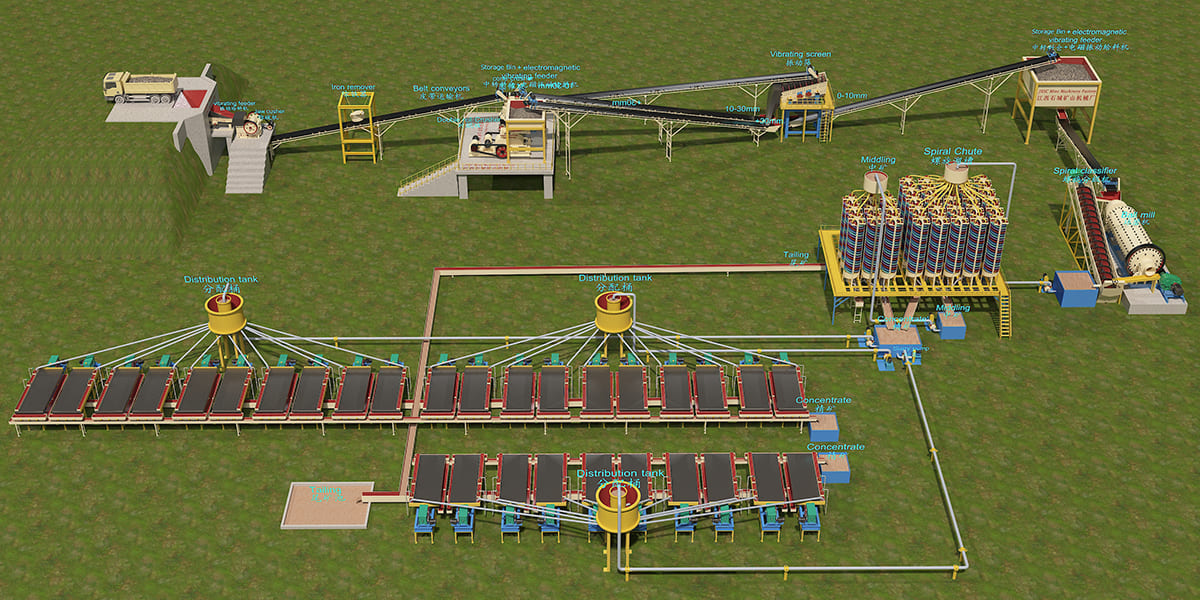

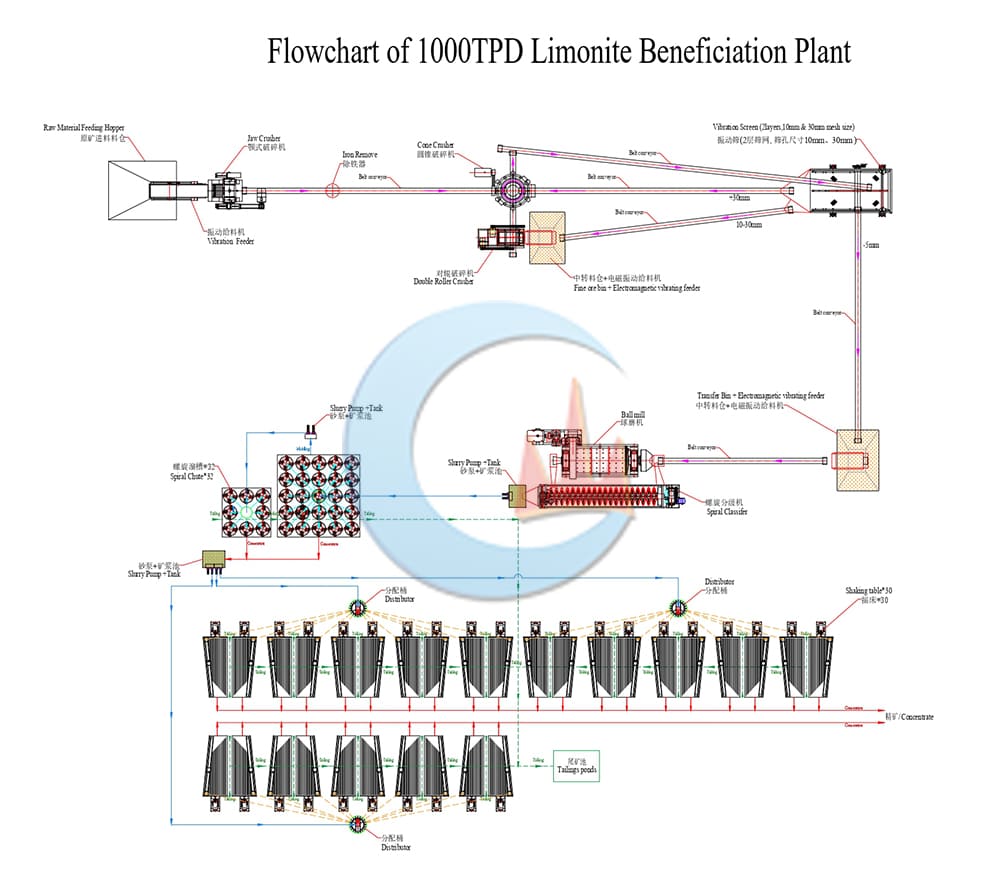

1000TPD Rock Limonite Ore Processing Plant

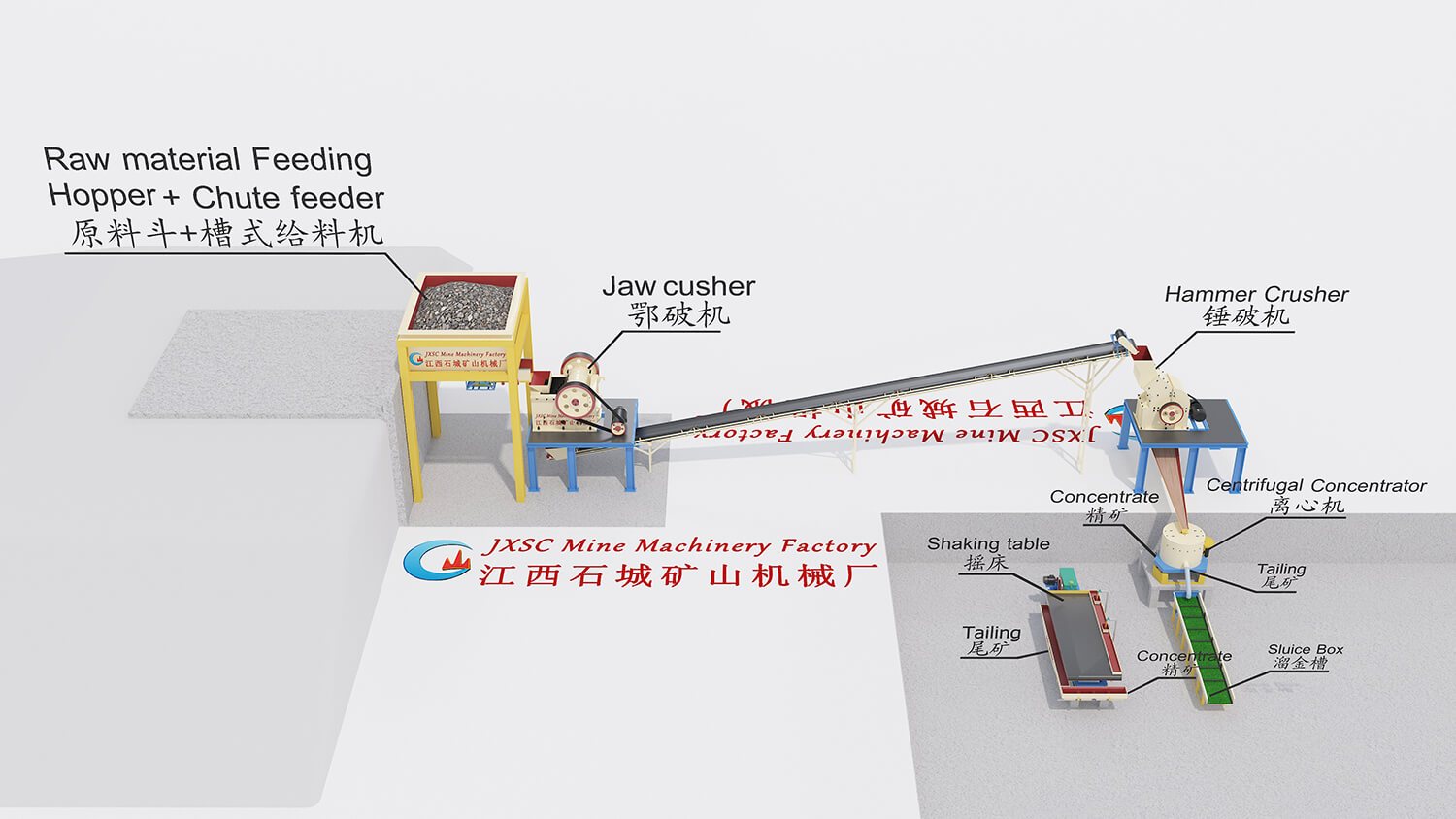

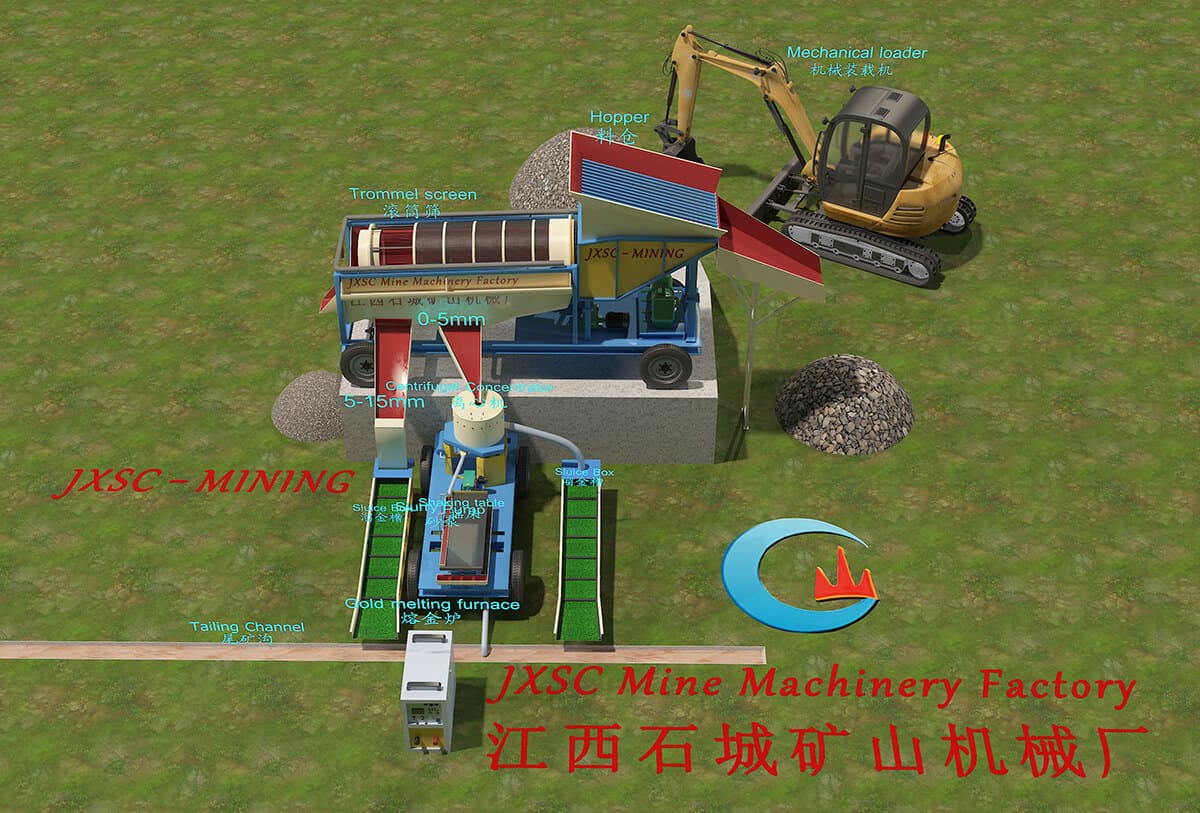

This Setup is a 1000 TPD Rock Limonite ore processing plant, configured with raw material feeding, primary crushing, fine crushing, screening, ball mill grinding, and gravity separation to separate and upgrade Limonite concentrate.

The Limonite ore raw material stone is fed to the primary jaw crusher by a vibration feeder, so can feed rock chrome ore smoothly and evenly. The vibration feeder is equipped with a grizzly bar to separate oversize material from the grizzly and direct it to a primary jaw crusher. Under the grizzly, small-sized material is conveyed to the fine crusher. So as can increase the crushing effect of the primary jaw crusher.

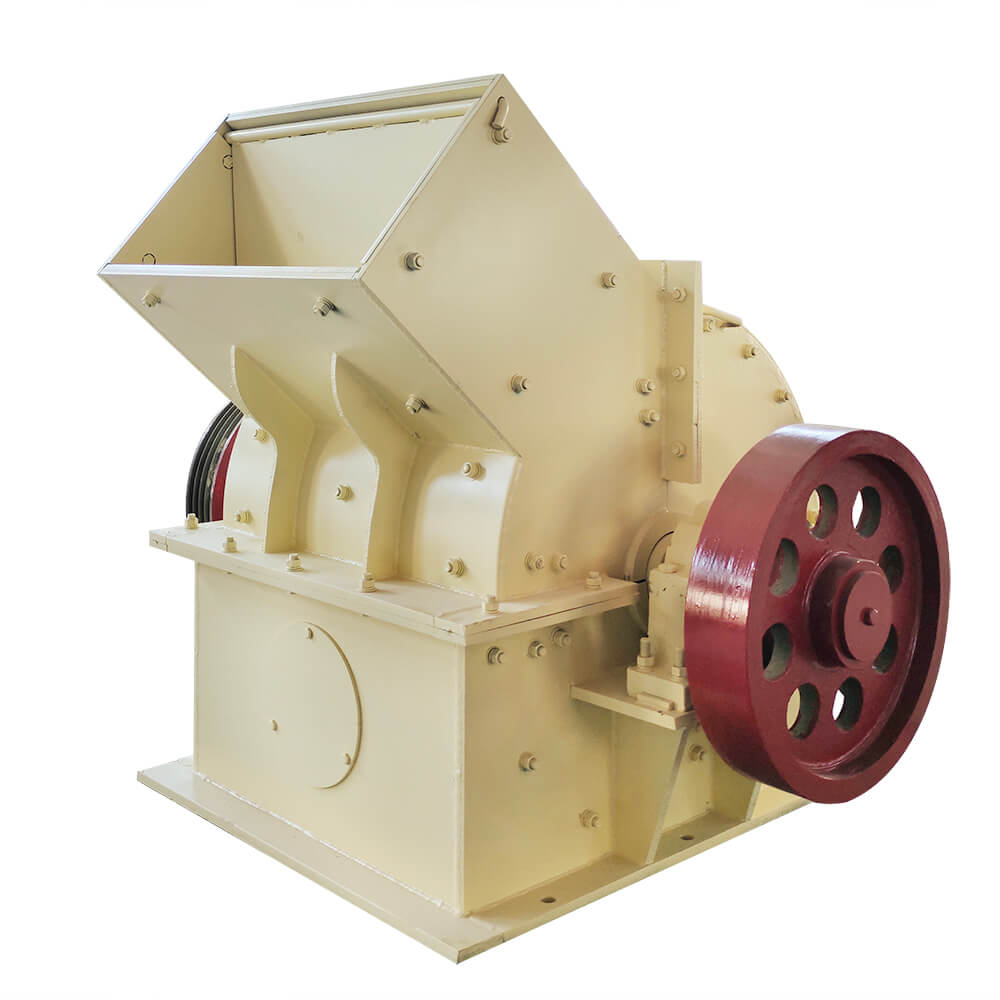

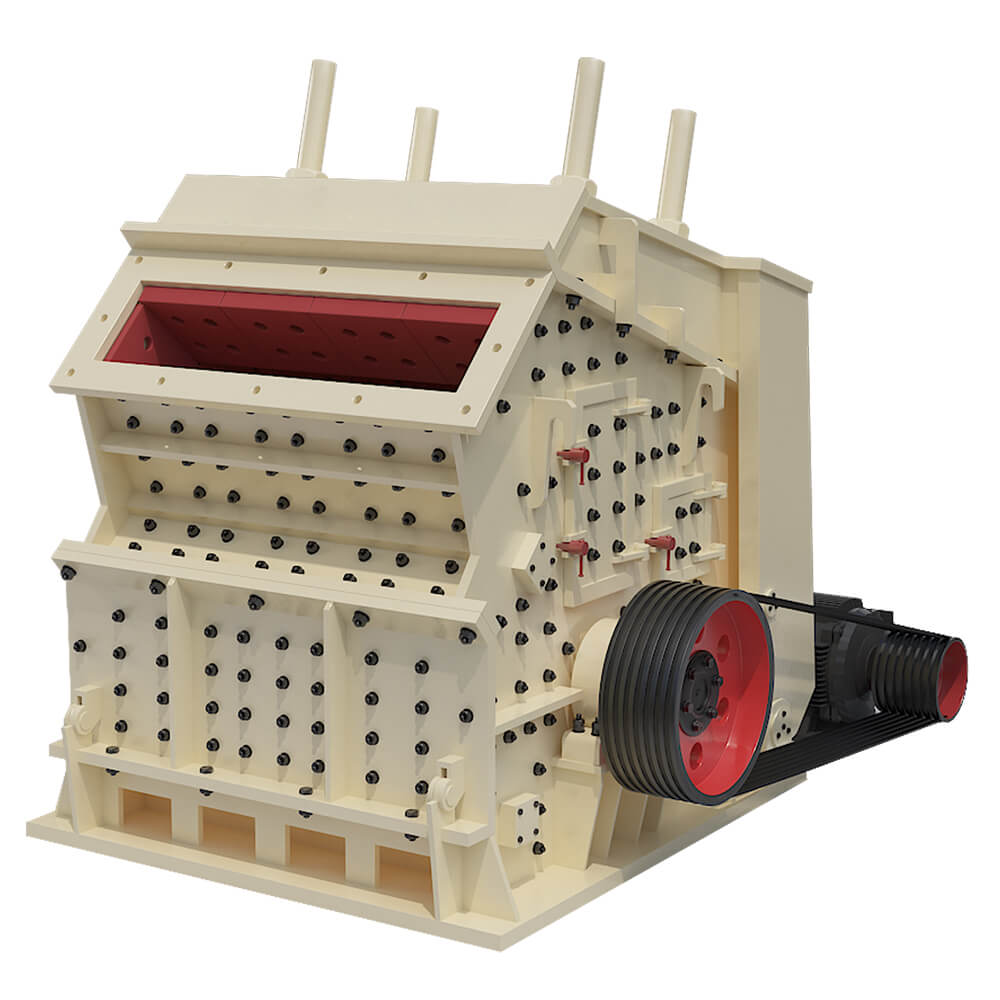

The primary jaw crusher is for crushing big rock chrome ore to a smaller size, and the output material goes to the next fine crushing machine cone crusher. The cone crusher crushed rock Limonite to below 30 mm is suitable to feed to the ball mill, but firstly will go to a vibration screen for screening out oversize larger than 30mm and sent back to the cone crusher for crushing again. 5 to 30mm will go to the double roller crusher for crushing again. Under screens 0 to 5mm go to the storage bin before the ball mill. If a small capacity plant, the cone crusher can be replaced by another type of fine crusher, such as a fine jaw crusher or hammer crusher, or impact fine crusher, etc.

The 0-5mm powder material will be sent to the ball mill smoothly by an electromagnetic vibration feeder and a belt conveyor. The ball mill is for grinding 0-5 mm into a small powder. It works together with the spiral classifier, so the overflow slurry from the classifier is about 80% 200 mesh powder, the oversize particles from the classifier will go back to the ball mill grinding again, to form a closed-loop.

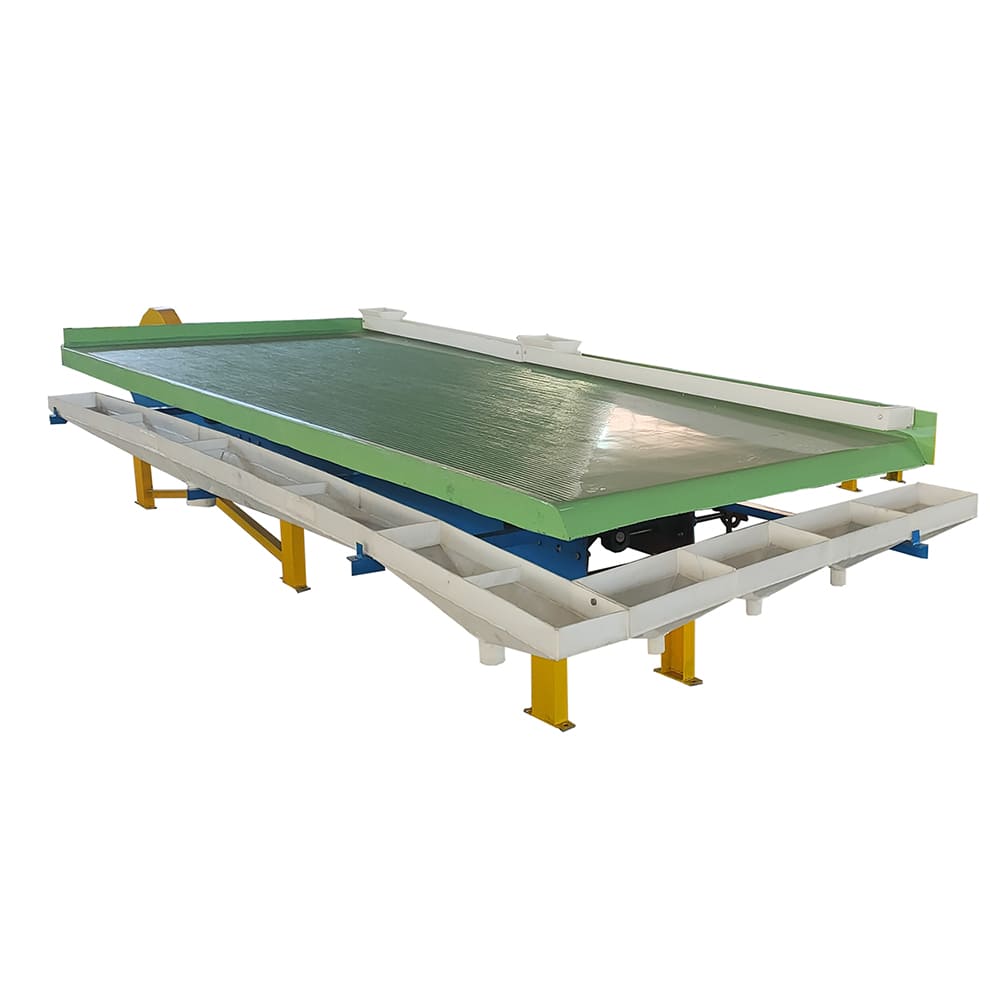

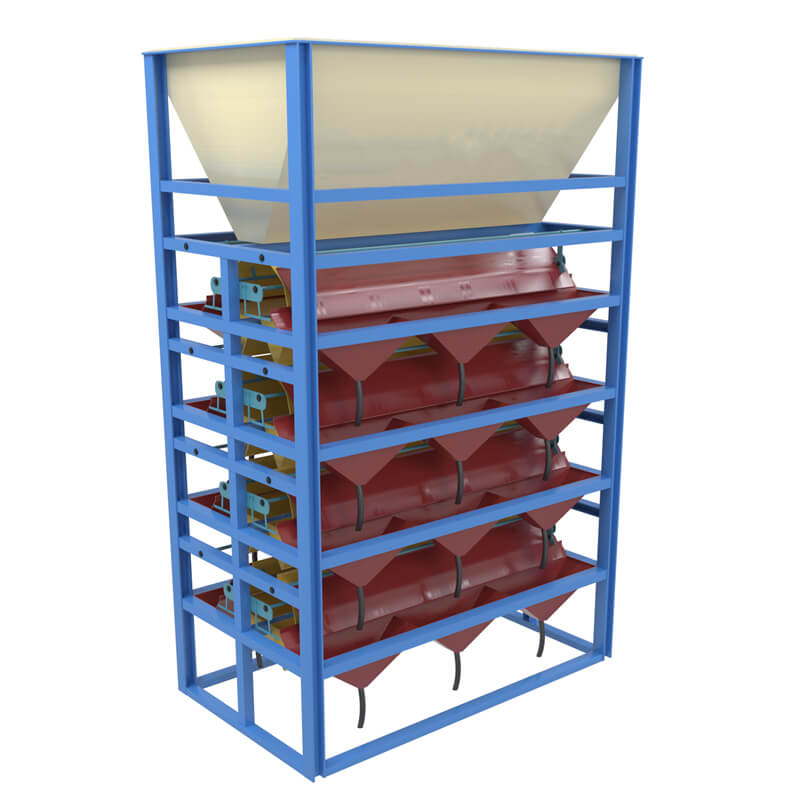

The 200 mesh slurry will be pumped to a gravity separation machine, spiral chute, and shaking table. The spiral chute is for primary concentration. In order to increase the Chrome recovery ratio to the maximum, we use a 2-stage spiral chute separation. The middling material from the 1st stage spiral chute group will be pumped to the 2nd stage spiral group, to recover as much Limonite as possible.

All the heavy concentrate ore that is discharged from the two-stage spiral group will go to the shaking table to concentrate again, to get higher-grade Limonite to concentrate.

This setup plant design can be customized according to the customer’s Limonite ore conditions. If they need a much higher grade Limonite concentrate, they can consider adding a high-intensity magnetic separator at the final stage.