Electrostatic Separators

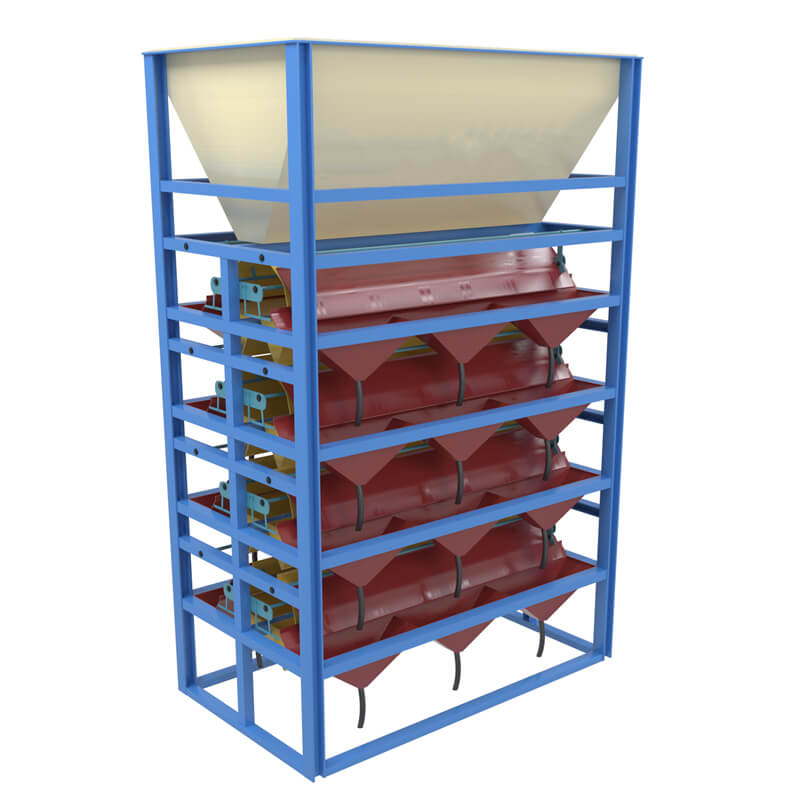

Electrostatic Separators Arc plate electrostatic separator It is suitable for the separation and selection of manganese ore, ilmenite, high tin tungsten ore, rutile, garnet, tantalum-niobium ore, chromite, rare earth ore, monazite, zircon, conductive and non-conductive minerals. Capacity: 1-3 t/hFeeding Size: 0-3 mm Roller electrostatic separator It is widely used to separate titanium, zircon sand, rutile, monazite, iron, tungsten, tantalum-niobium, tin, […]

Electrostatic Separators Read More »