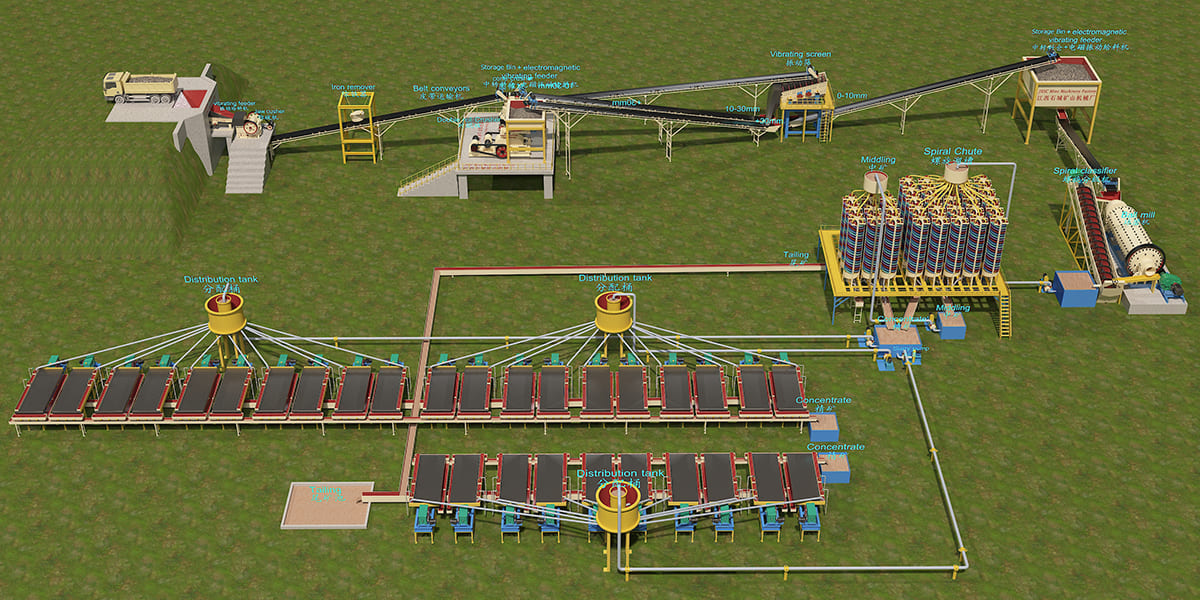

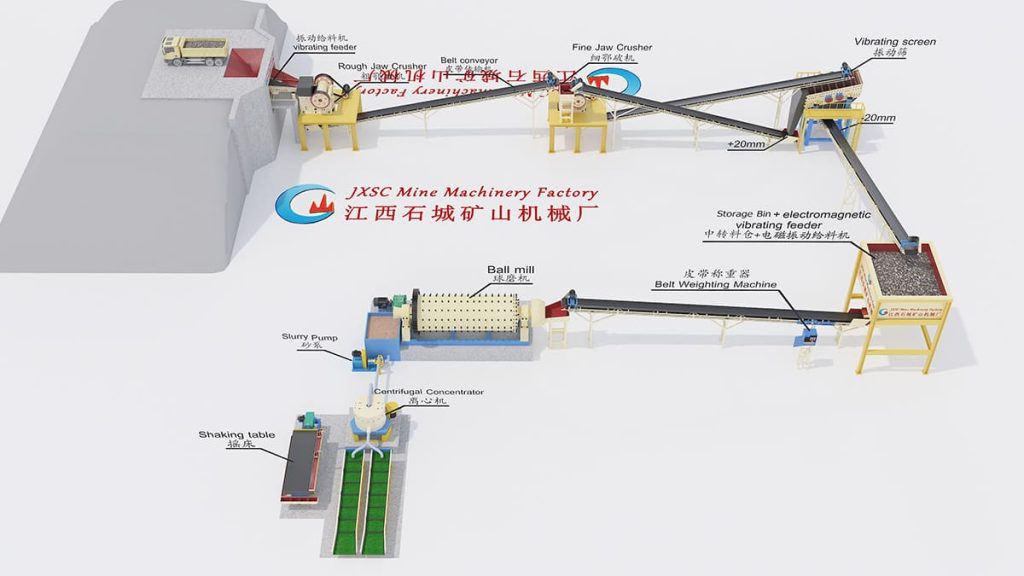

JXSC has provided a successful 30TPH rock gold gravity separation plant in Congo. We designed the ore process plant flowchart and plant layout drawing according to ore conditions. We provided a complete set of plant machines to the mine site.

EPCS

Engineering, Procurement & Construction Services

Case Study: Rock Gold Processing Project

Project Overview

Minerals

Rock Gold Ore

Capacity

30 TPH

Feed Size

<340 mm

Location

Congo

Project Process

Solutions & Process

Rock Gold Gravity Separation Plant Processing

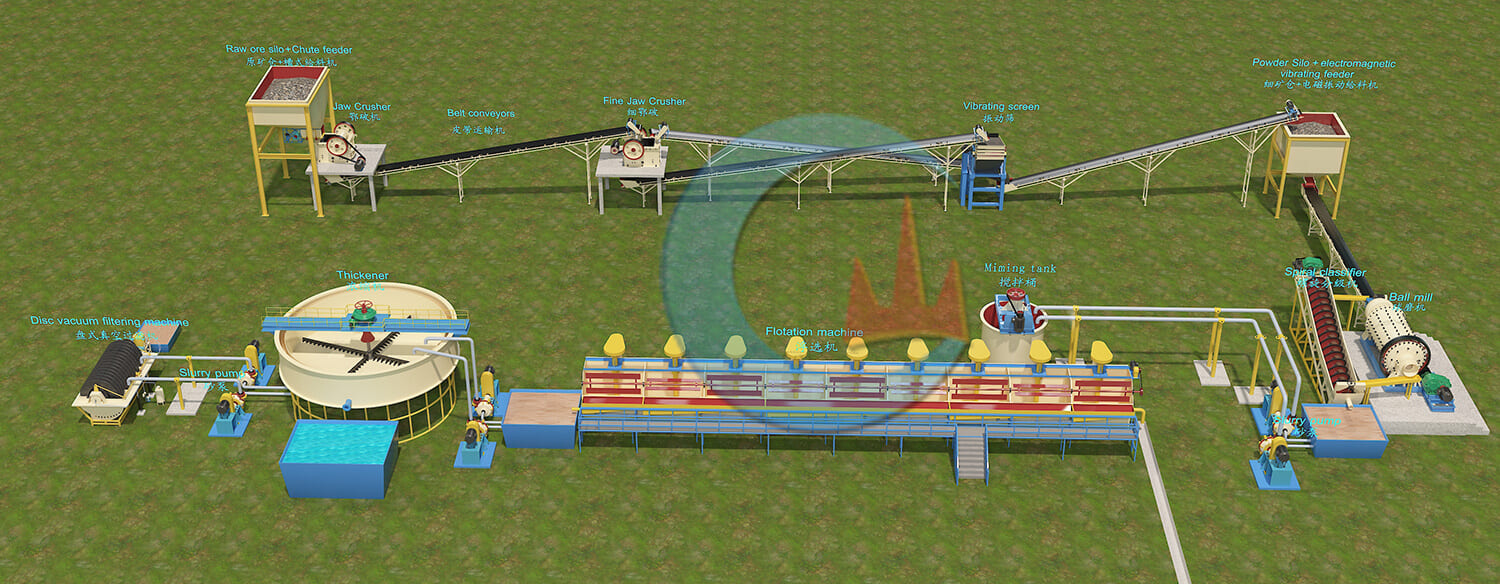

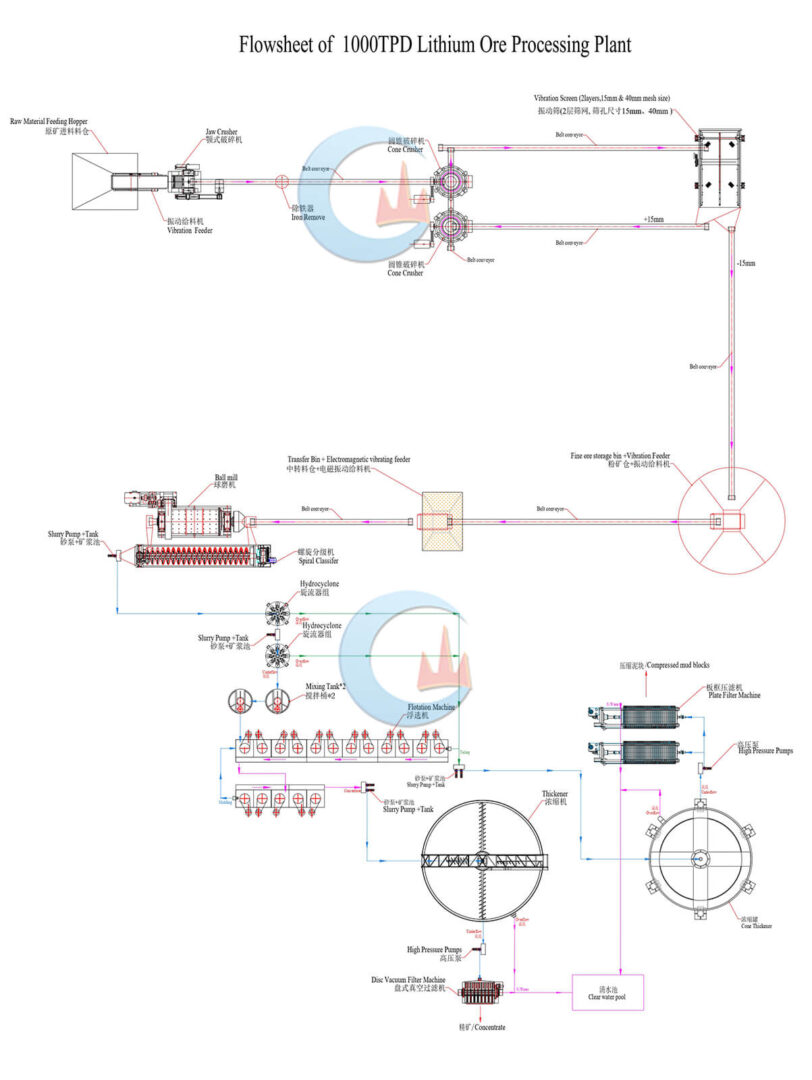

This setup is a 30TPH rock gold processing plant, comprising a vibration feeder, primary jaw crusher, fine jaw crusher, vibrating screen, ball mill, gold centrifugal concentrator, shaking table, sluice box, slurry pump, belt conveyor, and gold smelting furnace.

This system is complete from feeding rock gold raw ore to get the final gold bar.

According to the rock ore information obtained from the customer, the rock needs to be ground to a final size of 0-1mm to release gold from the rock. So we designed this flowchart accordingly.

The detailed process flow explanation is as follows:

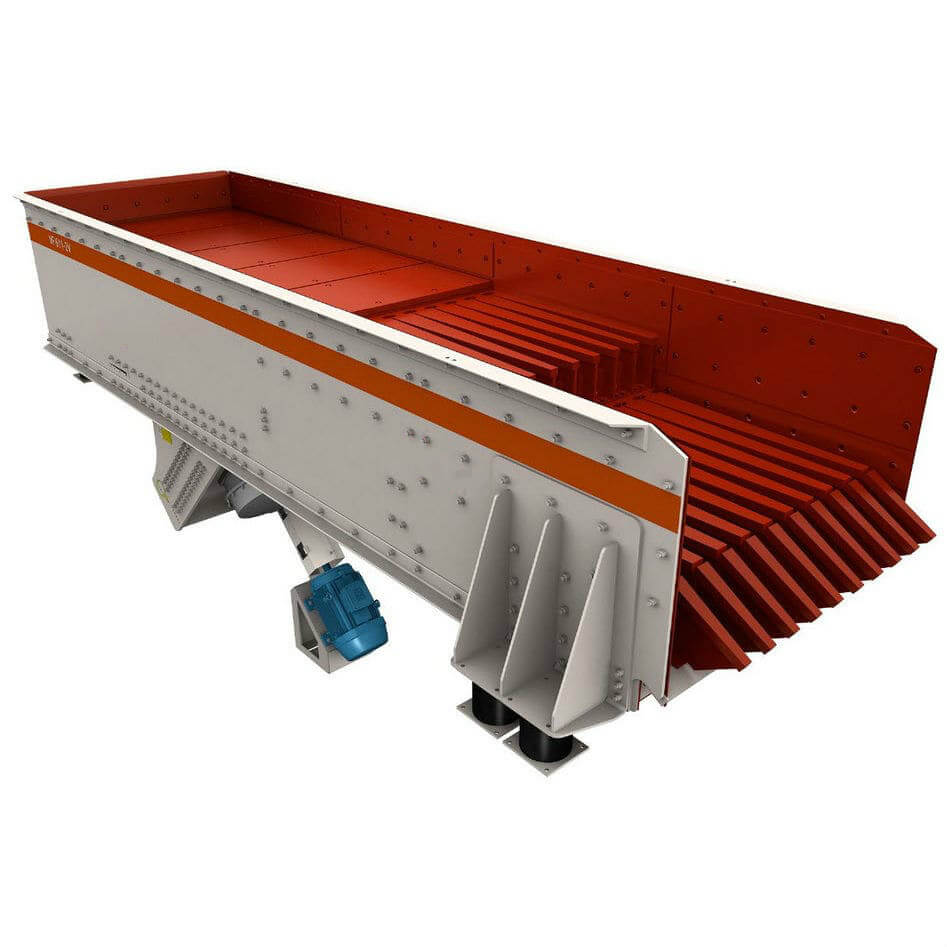

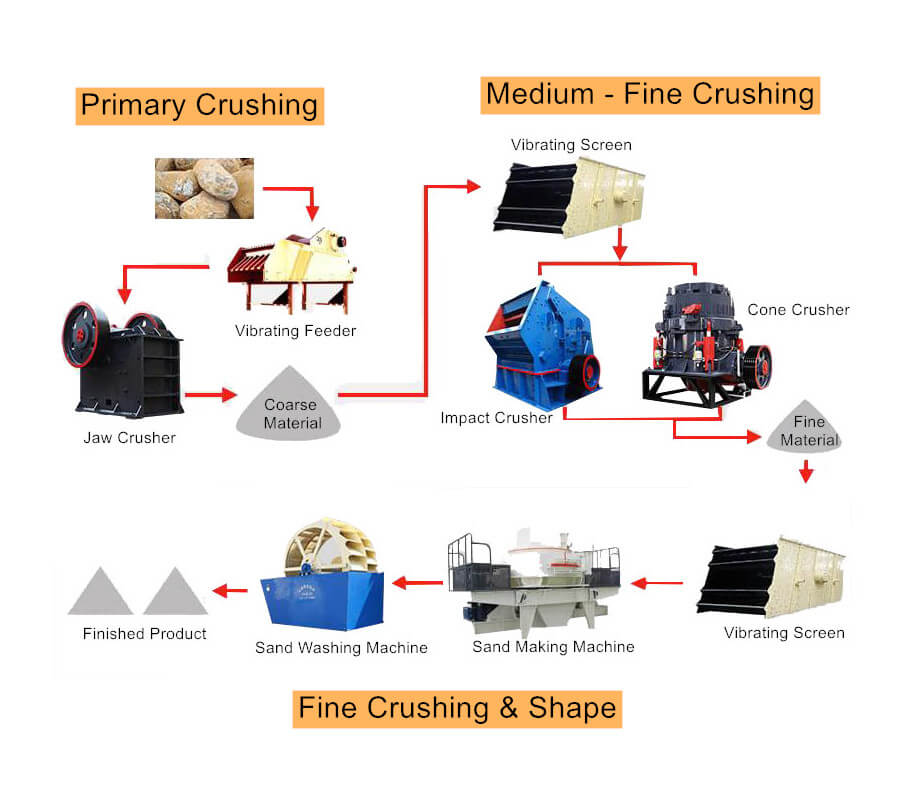

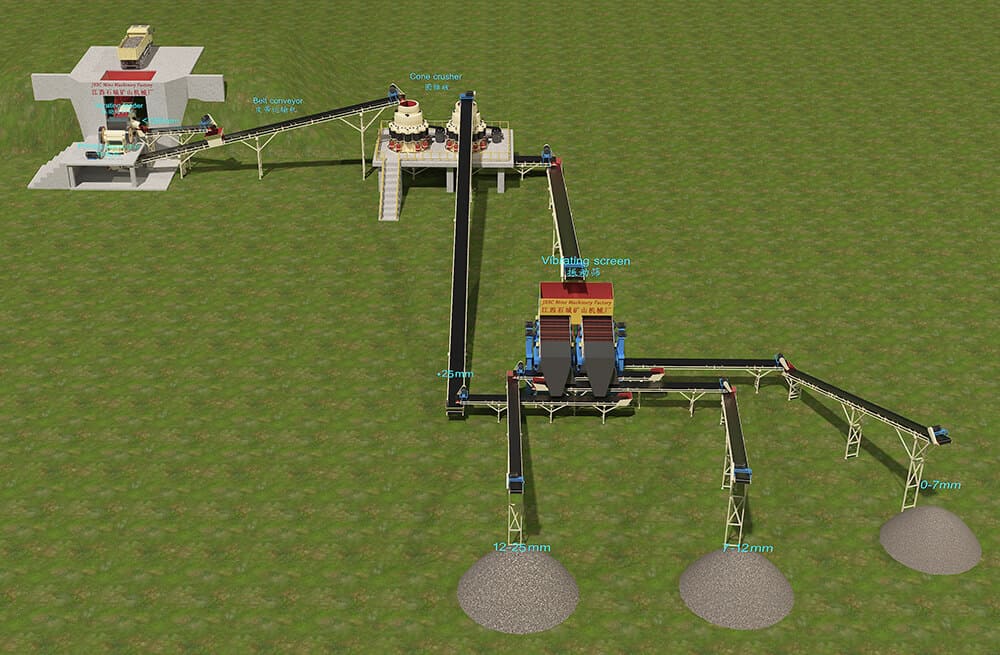

- The wheel loader or dump truck feeds rock ore to the raw material hopper, then through the vibration feeder smoothly feeds into the jaw crusher.

- The first primary jaw crusher roughly crushes big rocks to a medium size below 100mm. Its output goes to the second stage fine jaw crusher for further crushing to a small size of 0-30mm by belt conveyor.

- The 0-30mm material will go to the vibration screen, to screen out 0-20mm, more than 20mm material will go back to the fine jaw crusher and all the 0-20mm materials from the vibration screen will be sent to a transfer bin before the ball mill.

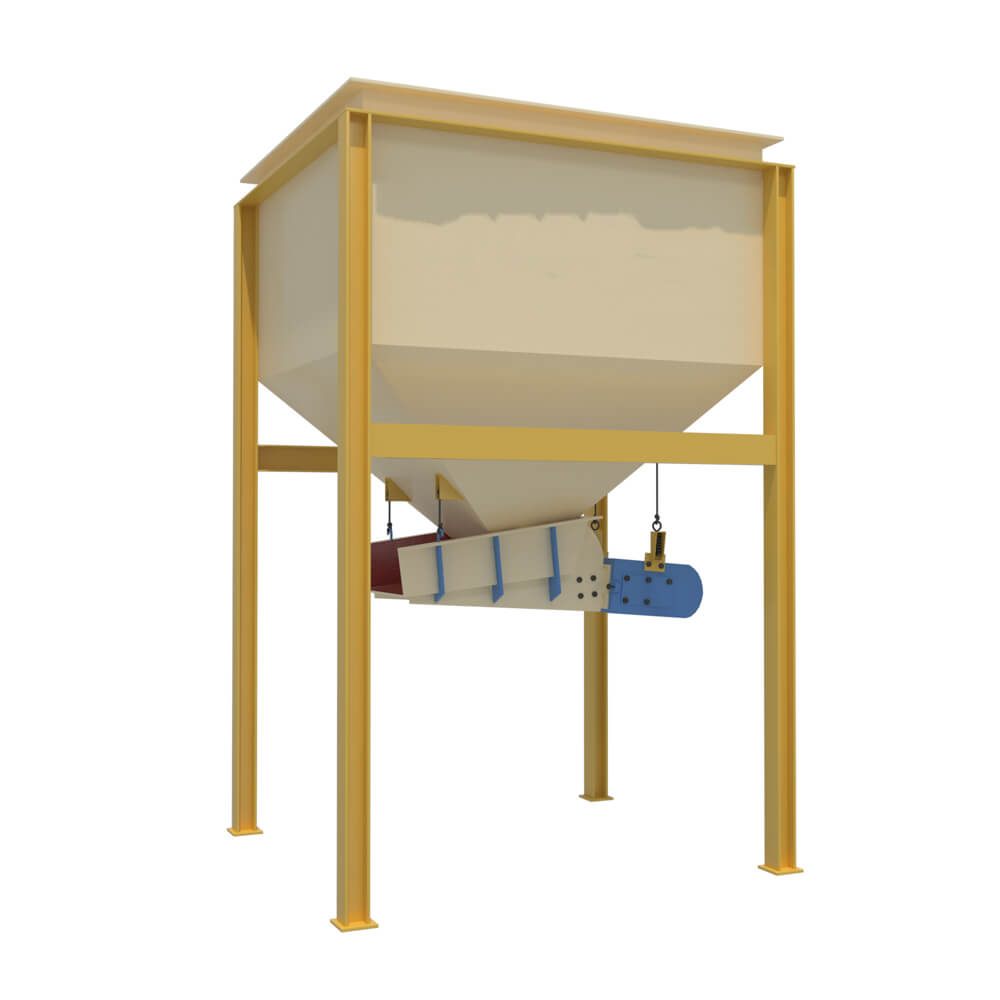

- The electromagnetic vibrating feeder is installed under the transfer bin to evenly feed 0-20mm fine ore to the ball mill via belt conveyor.

- The ball mill grinds fine ores of 0-20 mm to 0-1mm so that the gold concentrate can be released from rocks.

- The 0-1 mm slurry material will go to the gold centrifugal concentrator by slurry pump or by gravity flow.

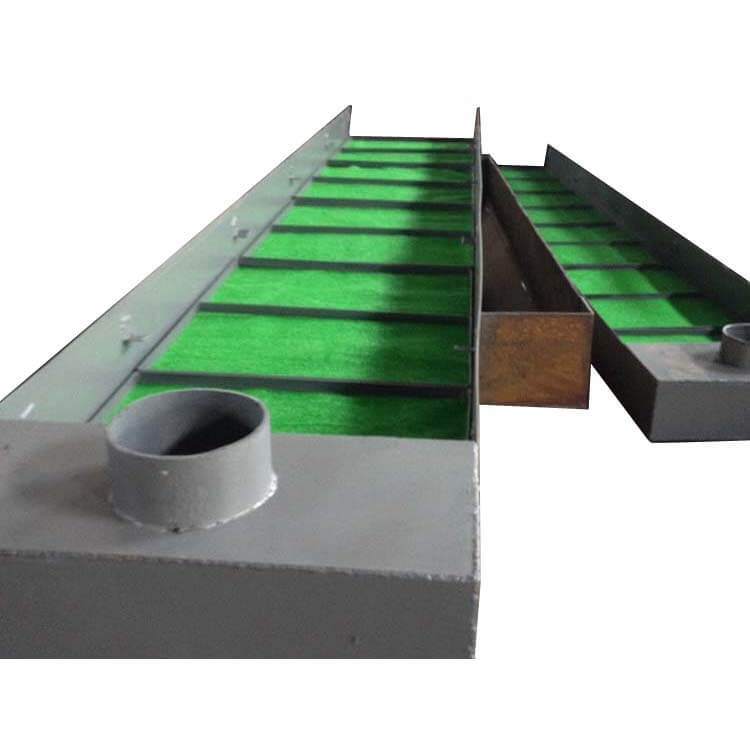

- Gold Centrifugal concentrator, shaking table and sluice box are gold separators and concentration machines. The gold centrifugal concentrator is for primary concentrating gold. The Concentrate ore discharged from the centrifugal concentrator will go to the shaking table for further separation of gold to further increase gold purity.

- Tailing discharged from the centrifugal concentrator will go to the sluice box to recover more gold. In this way, customers can get as much gold concentrate from this gold separator system.

- Finally, all gold concentrates are sent to a gold smelting furnace for purification so that customers can get gold bars.

This flowchart solution has the following advantages:

- The crushing rate is high, suitable for any type of rock, especially hard quartz rock gold.

- The gold recovery rate can reach as high as 80-90%. A ball mill can grind rock to a small size, so more fine gold can be released from rocks, then use a three-stage gold separator system to extract the released fine gold.

- Operation is simple, and maintenance is easy and simple.

- Investment is affordable, and payback is fast.

Related Cases

We are a leading provider of innovative and efficient mining equipment and solutions. With years of experience in the industry, we specialize in designing and manufacturing high-quality machines tailored for various mineral processing needs, including gold, diamond, copper, tin, manganese, chrome, titanium, and other ore separations. Our commitment to technology and customer satisfaction drives us to deliver customized solutions that enhance productivity and ensure environmentally sustainable practices. Explore our extensive portfolio of successful case studies and discover how JXSC can transform your mining operations, helping you maximize your profitability while minimizing your ecological footprint. Choose Us—where technology meets efficiency in the world of mining!