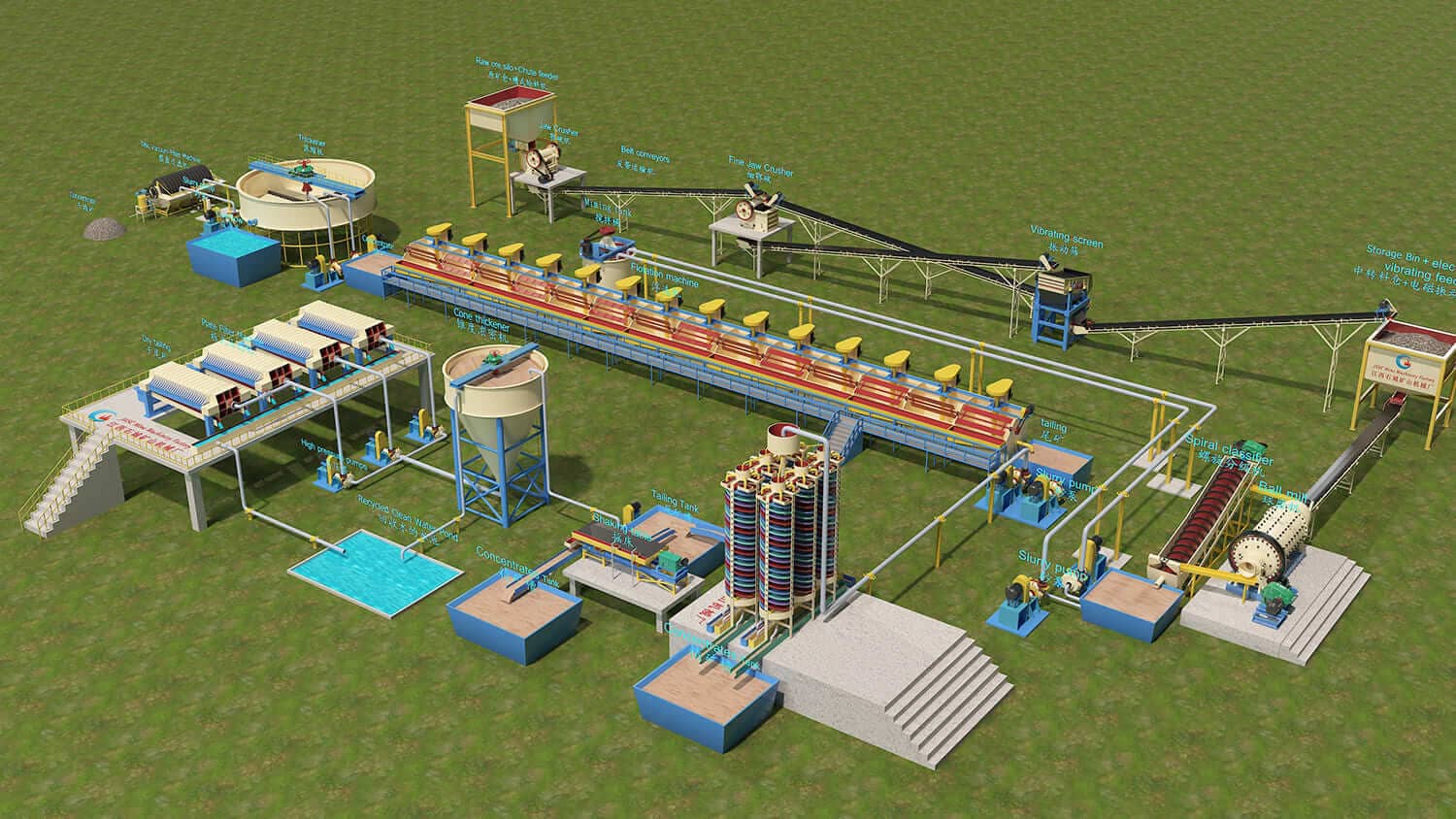

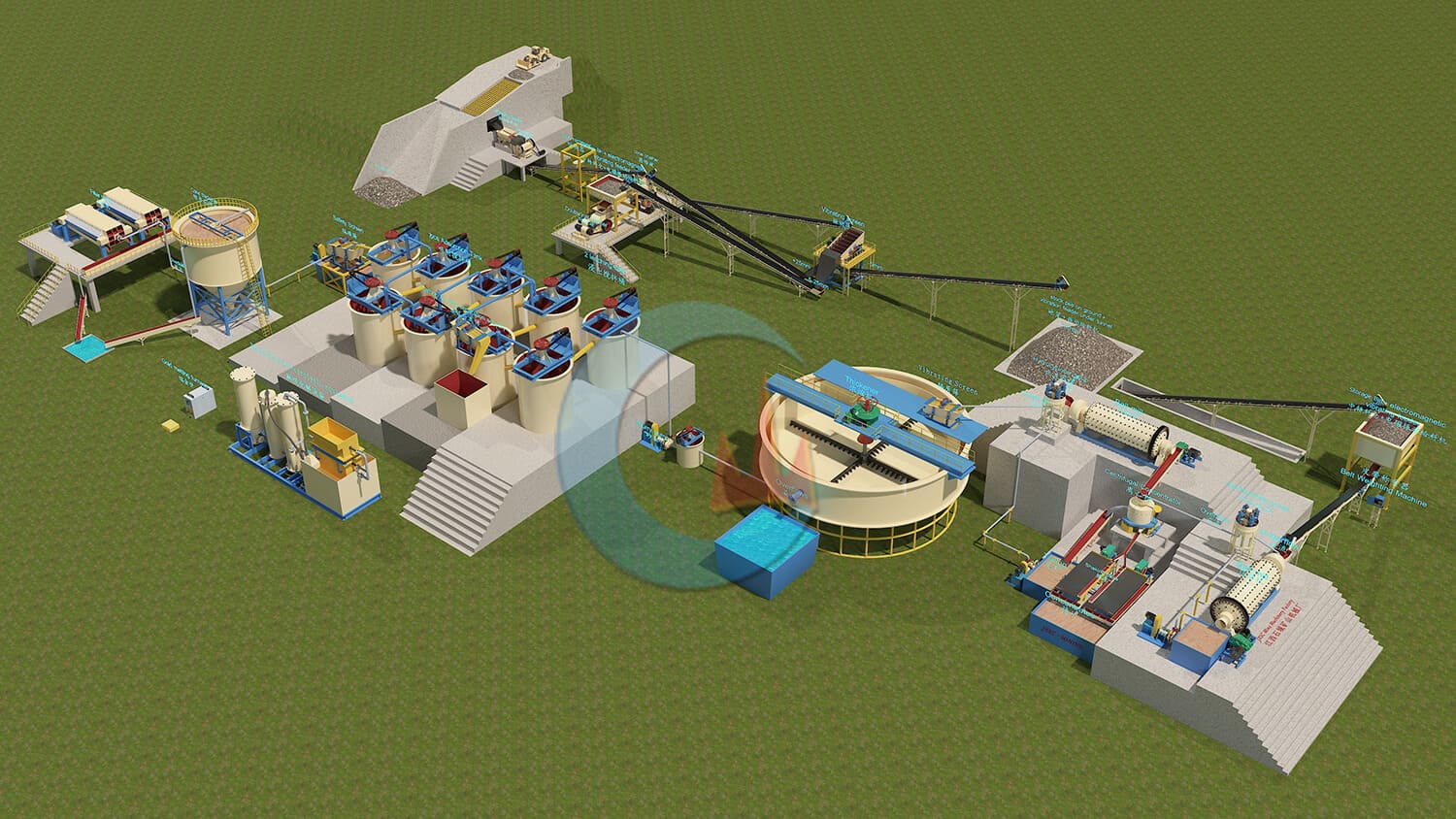

JXSC has provided a successful 15TPH chrome tailing process plant in South Africa. We designed the processing plant flowchart and plant layout drawing according to the client’s requirements. We provided a complete set of plant machines to the mine site.

EPCS

Engineering, Procurement & Construction Services

Case Study: Chrome Tailing Process Plant Project

Project Overview

Minerals

Chrome Tailings

Capacity

15 TPH

Feed Size

≤100 mm

Location

South Africa

Project Process

Solutions & Process

Our company has provided a complete 15TPH chrome tailing process plant in South Africa. It is very easy to operate. This plant is a very popular design in South Africa and Zimbabwe; many chrome owners prefer to apply it.

Our service for this project includes:

1. Design a whole plant flowchart and machine layout according to the chrome project conditions.

2. Provide Complete Set washing machines and all accessories.

3. Shipping all machines to the destination port in South Africa

4. Provide technical support& installation instructions.

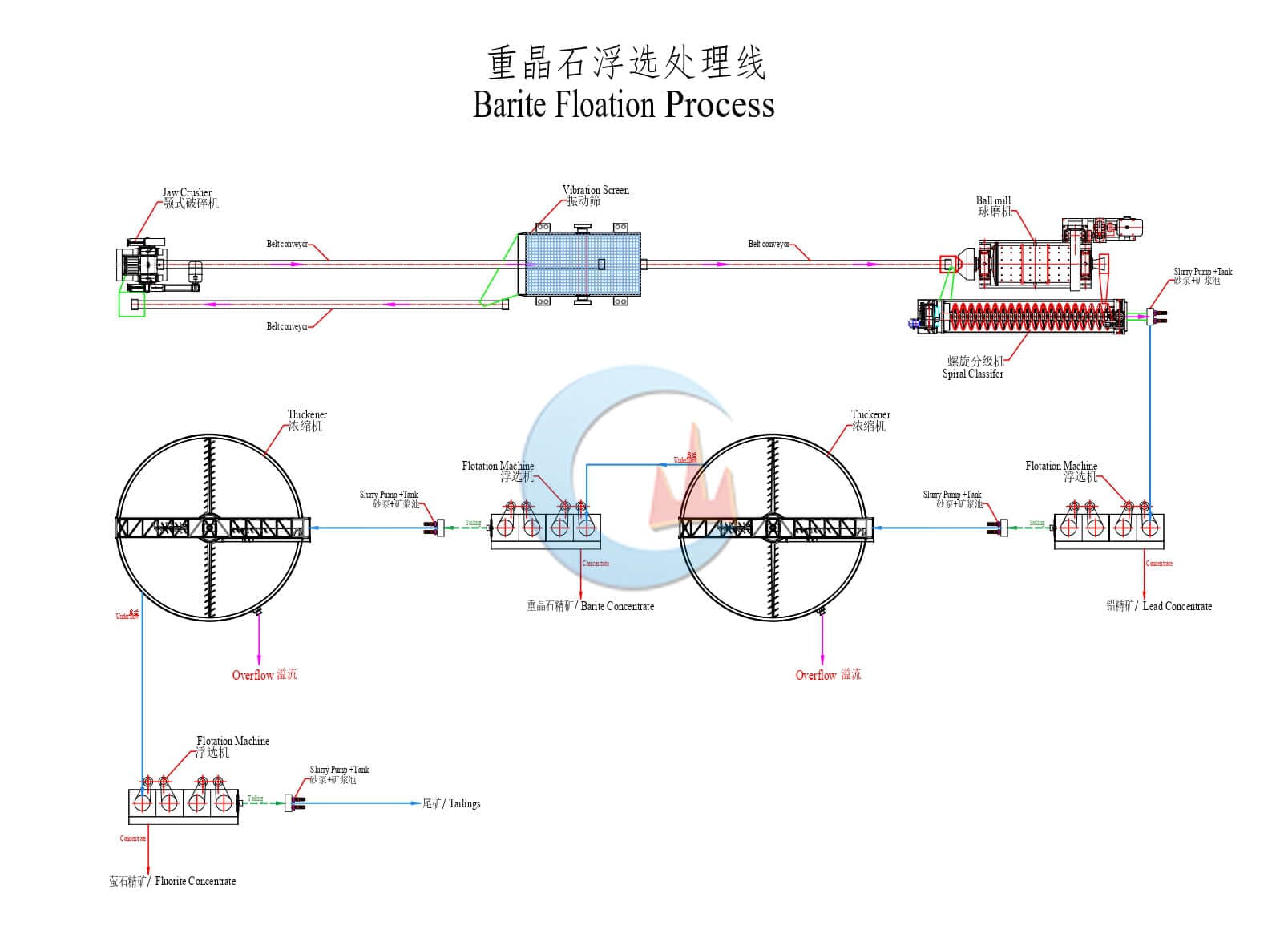

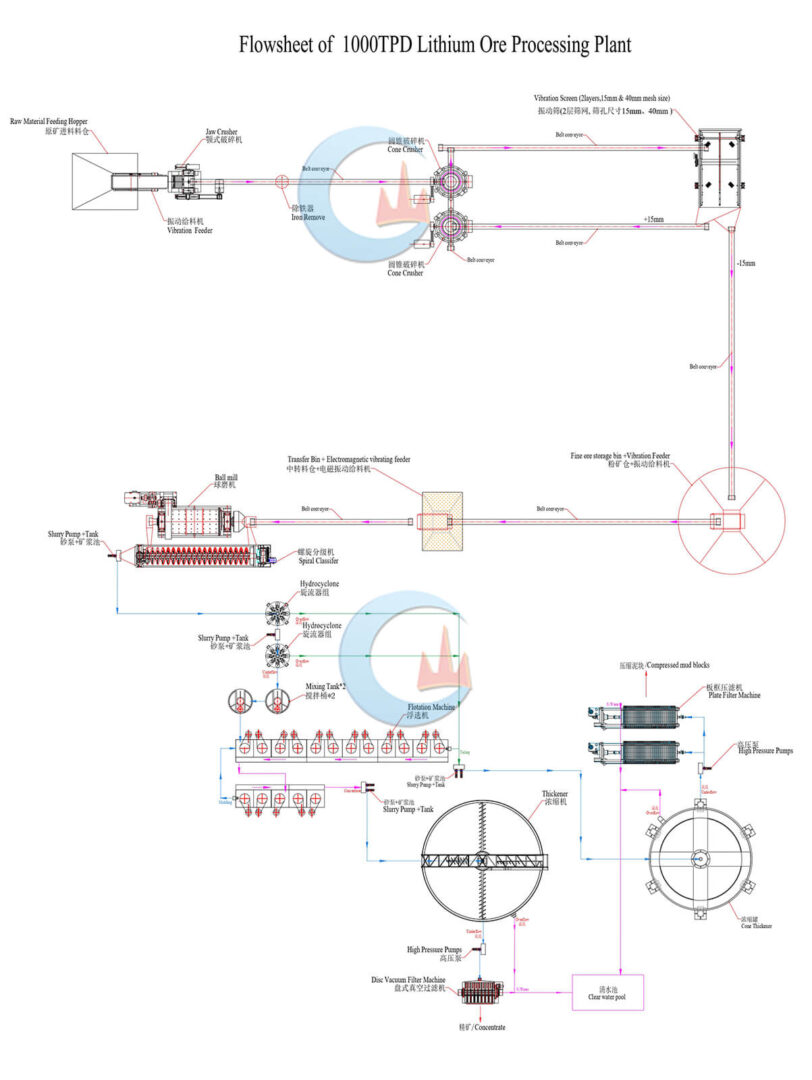

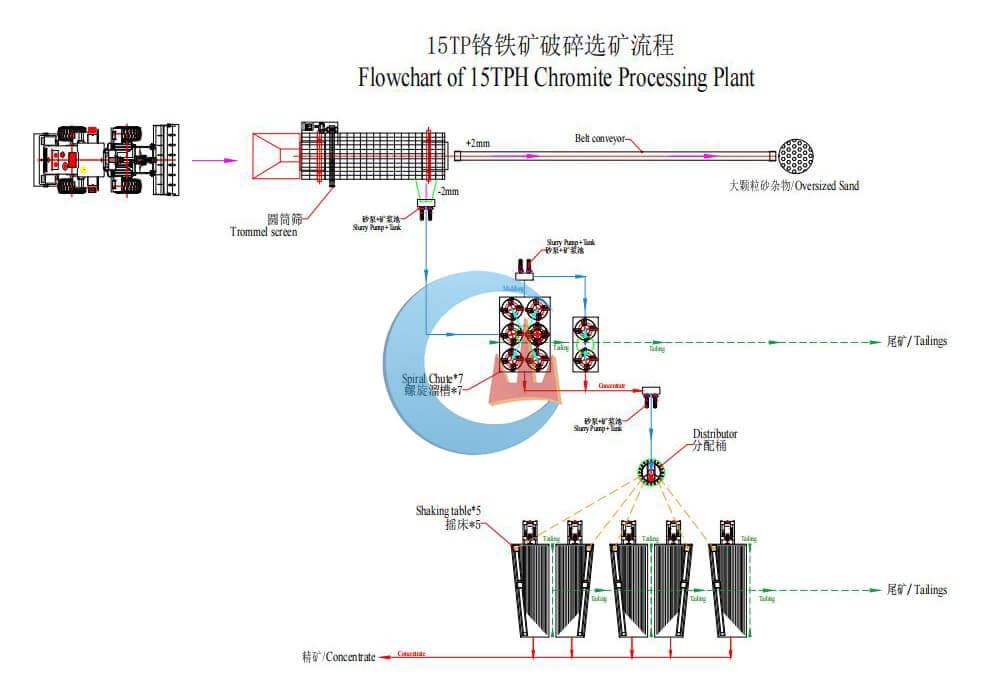

South Africa Chrome Tailing Process Flowchart

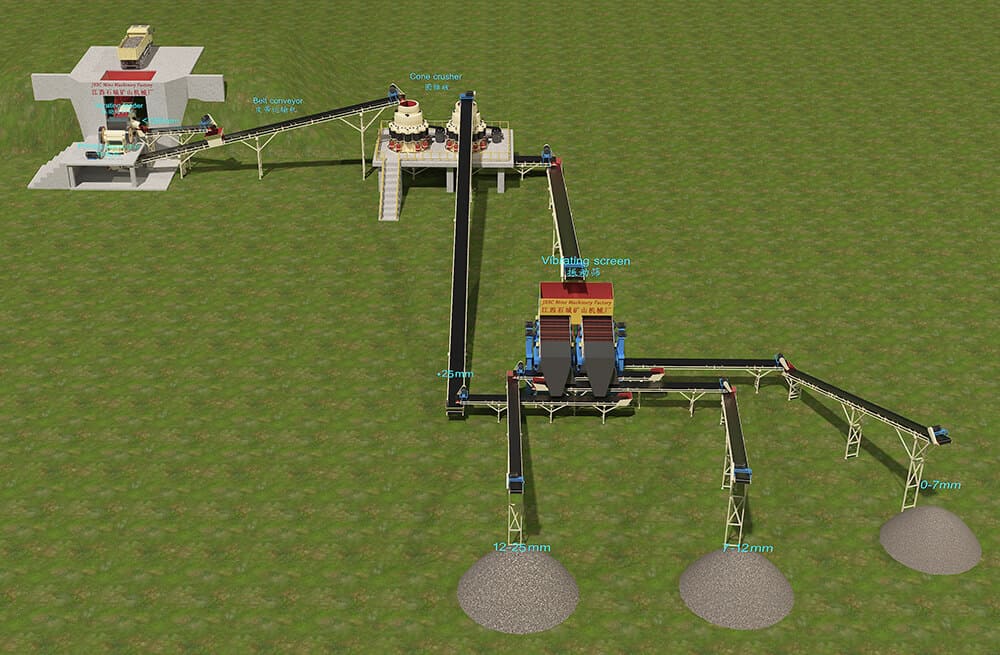

This plant can recover chrome from chrome tailings, based on three stages gravity separator, and will get a high-grade chrome concentrate. The design and capacity can be customized based on the customers’ raw materials conditions and requirements. Welcome to contact us for more details.

South Africa 15TPH Chrome Tailing Process Plant Equipment

- Trommel screen GT1020, 1 set

- Belt conveyor DT75-500, 1 set

- Slurry pump 4/3 inch, 1 set

- Slurry pump 3/2 inch, 2 sets

- Spiral chute, 7 sets

- Shaking table, 5 sets

- Water pump, 1 set

Customer Questions & Our Answers

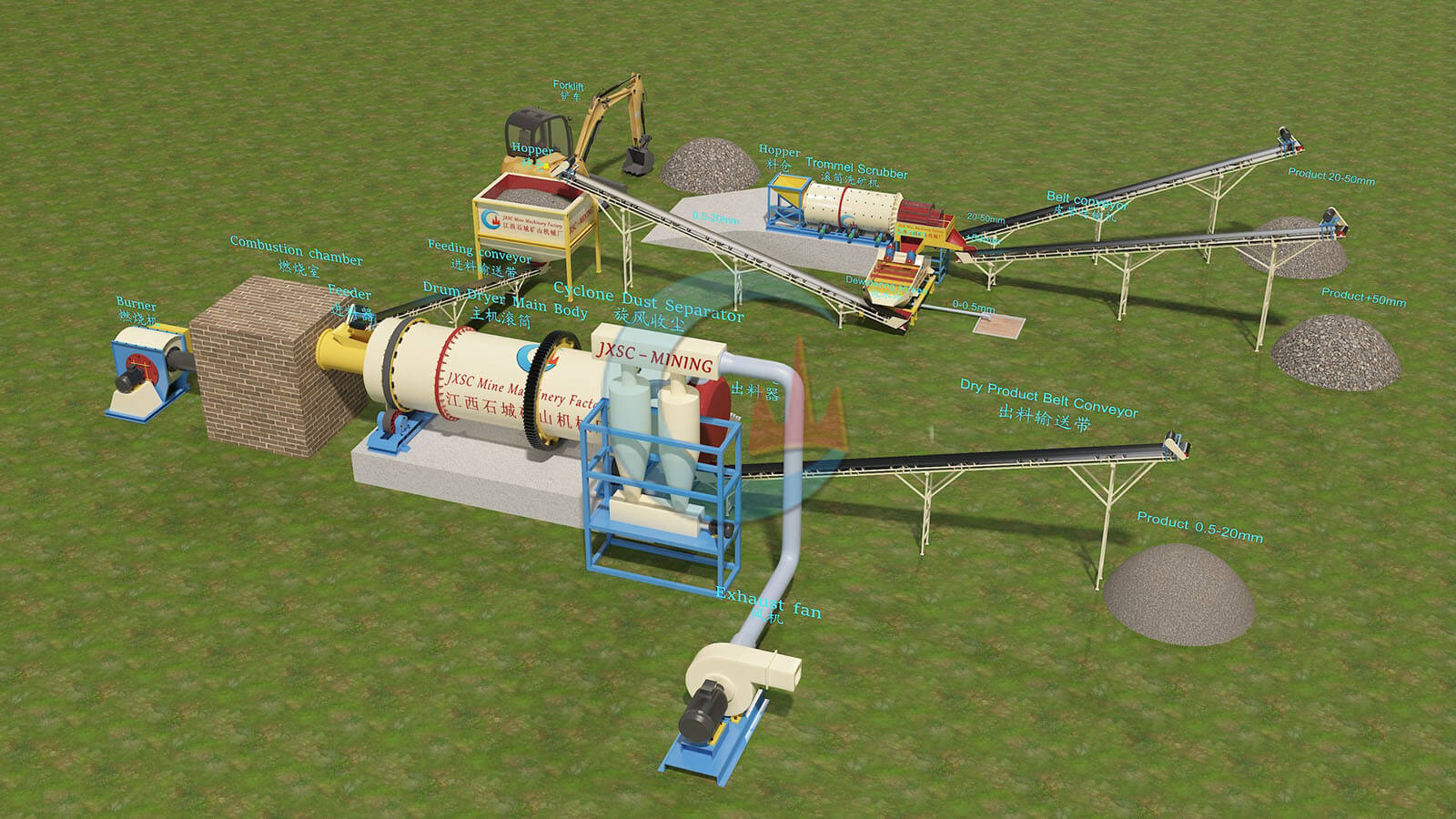

1. What’s the difference between the trommel scrubber and trommel screen?

The trommel scrubber is used for washing raw materials with sticky clay, while the trommel screen is used for cleaning raw materials with normal sand and soil.

2. Why does the spiral chute need two stages?

The mid concentrate from the first stage spiral chute will go to the second stage spiral chute, which will make the chrome concentrate purer.

3. Why does the concentrate from the spiral chute need to go to the shaking table?

If the chrome concentrate needs to achieve a higher grade, the shaking table will be necessary. It relies on the dual action of reciprocating vibration of the bed surface and transverse water flow washing to finely stratify minerals according to density, grain size, and shape.

4. How to dewater the concentrate?

The concentrate slurry can be pumped to the hydro cyclone for dewatering and recycling the water.

5. What is the particle size requirement for the feed ore?

The maximum feeding size of the trommel is 100 mm; it has big waste stones over 100mm, so a 100mm grizzly bar can be made on the hopper to remove the big waste stones.

6. What’s the water consumption of the whole line of machines?

The total water consumption will need approximately 50 m3 per hour, mainly for feeding water to the trommel screen and shaking table. The water consumption for the trommel screen is 2 times the capacity, for the shaking table is 2-3 m3 per hour per set.

7. What chrome recovery rate can be achieved?

The gravity recovery rate can reach 80–85%, final result will depend on the raw materials’ conditions.

Equipment In This Project

Related Cases

We are a leading provider of innovative and efficient mining equipment and solutions. With years of experience in the industry, we specialize in designing and manufacturing high-quality machines tailored for various mineral processing needs, including gold, diamond, copper, tin, manganese, chrome, titanium, and other ore separations. Our commitment to technology and customer satisfaction drives us to deliver customized solutions that enhance productivity and ensure environmentally sustainable practices. Explore our extensive portfolio of successful case studies and discover how JXSC can transform your mining operations, helping you maximize your profitability while minimizing your ecological footprint. Choose Us—where technology meets efficiency in the world of mining!