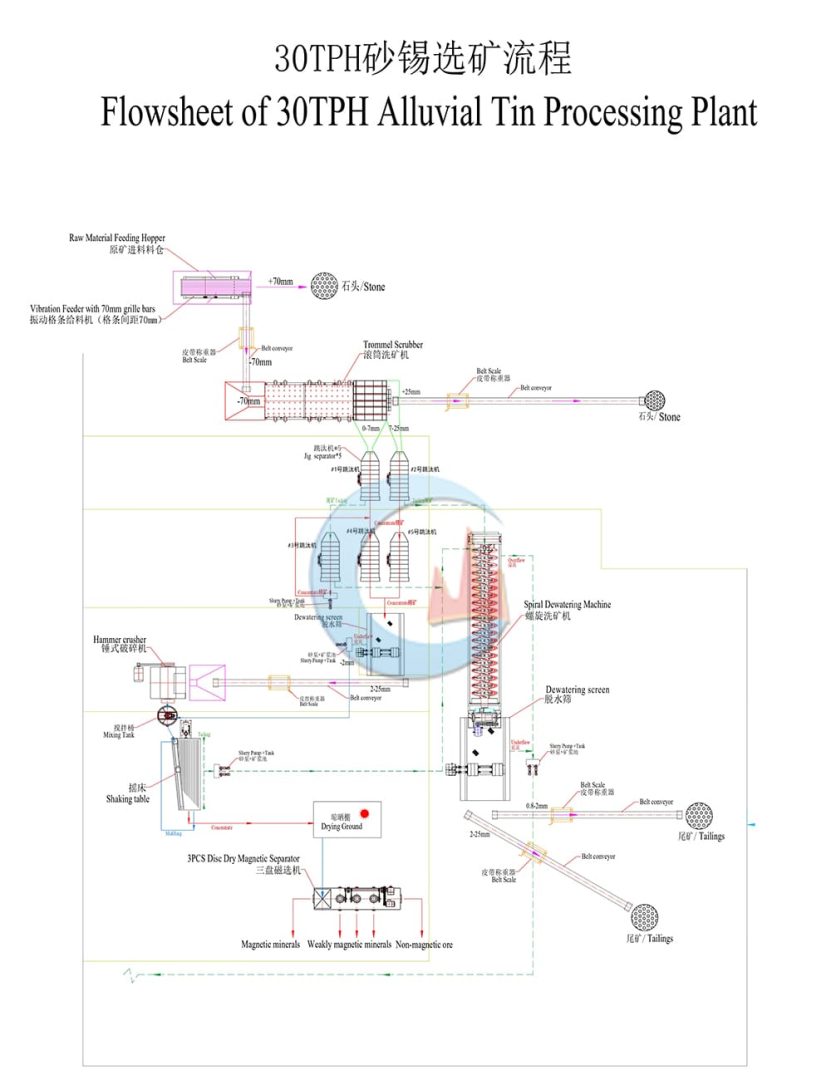

JXSC has provided a successful 30TPH alluvial tin processing plant in Uganda. We designed the processing plant flowchart and plant layout drawing according to the client’s requirements. We provided a complete set of plant machines to the mine site, and sent the engineer to the mine site for installation guidance.

EPCS

Engineering, Procurement & Construction Services

Case Study: Alluvial Tin Process Project

Project Overview

Minerals

Alluvial Tin

Capacity

30 TPH

Feed Size

≤ 70 mm

Location

Uganda

Project Process

Solutions & Process

Alluvial Tin Processing Plant in Uganda

This is a 30 tph tin processing plant.

The customer’s tin project information:

- Location: Uganda

- Raw ore condition: Alluvial tin mainly with a lot of sticky clay, with coarse tin concentrate and fine tin concentrates as well. Need to enrich coarse tin concentrate into fine powder to improve the grade.

- Customer’s main requirements: 30tph, a higher recovery rate as possible. High configuration. We need a dewatering machine to recycle water and tailing sand with reduced moisture content.

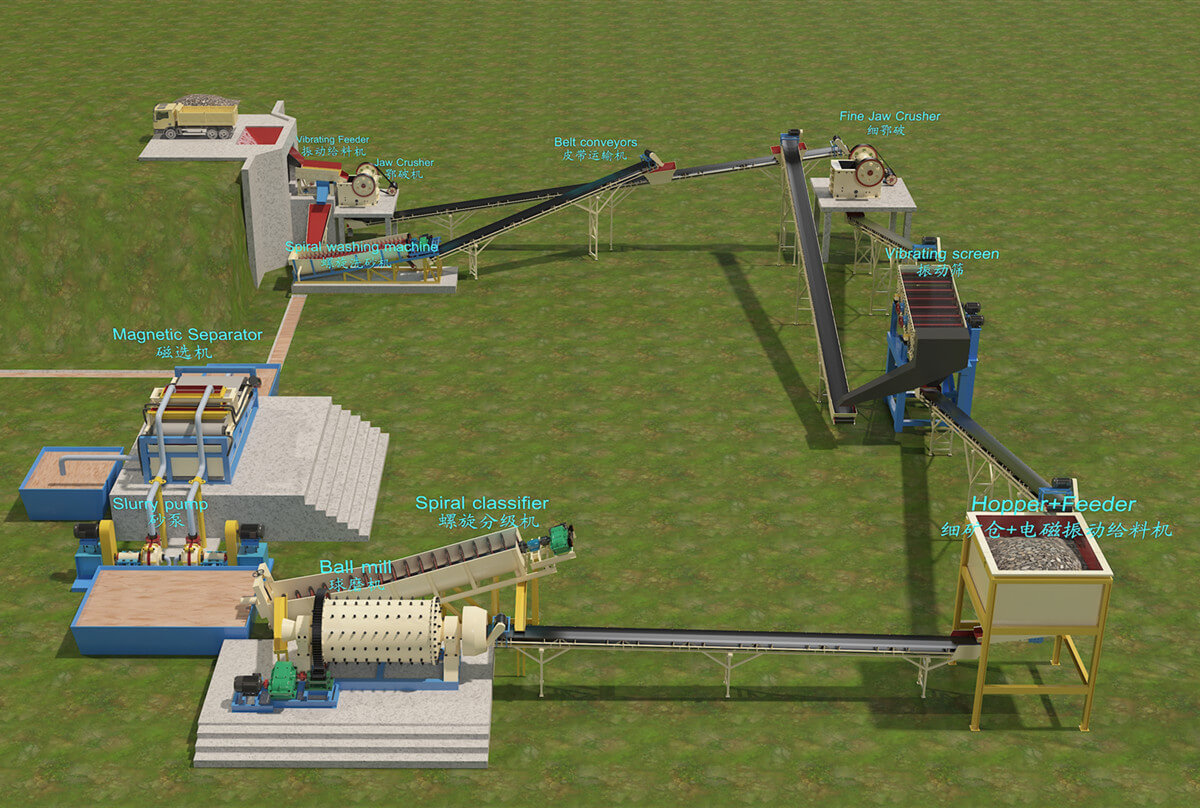

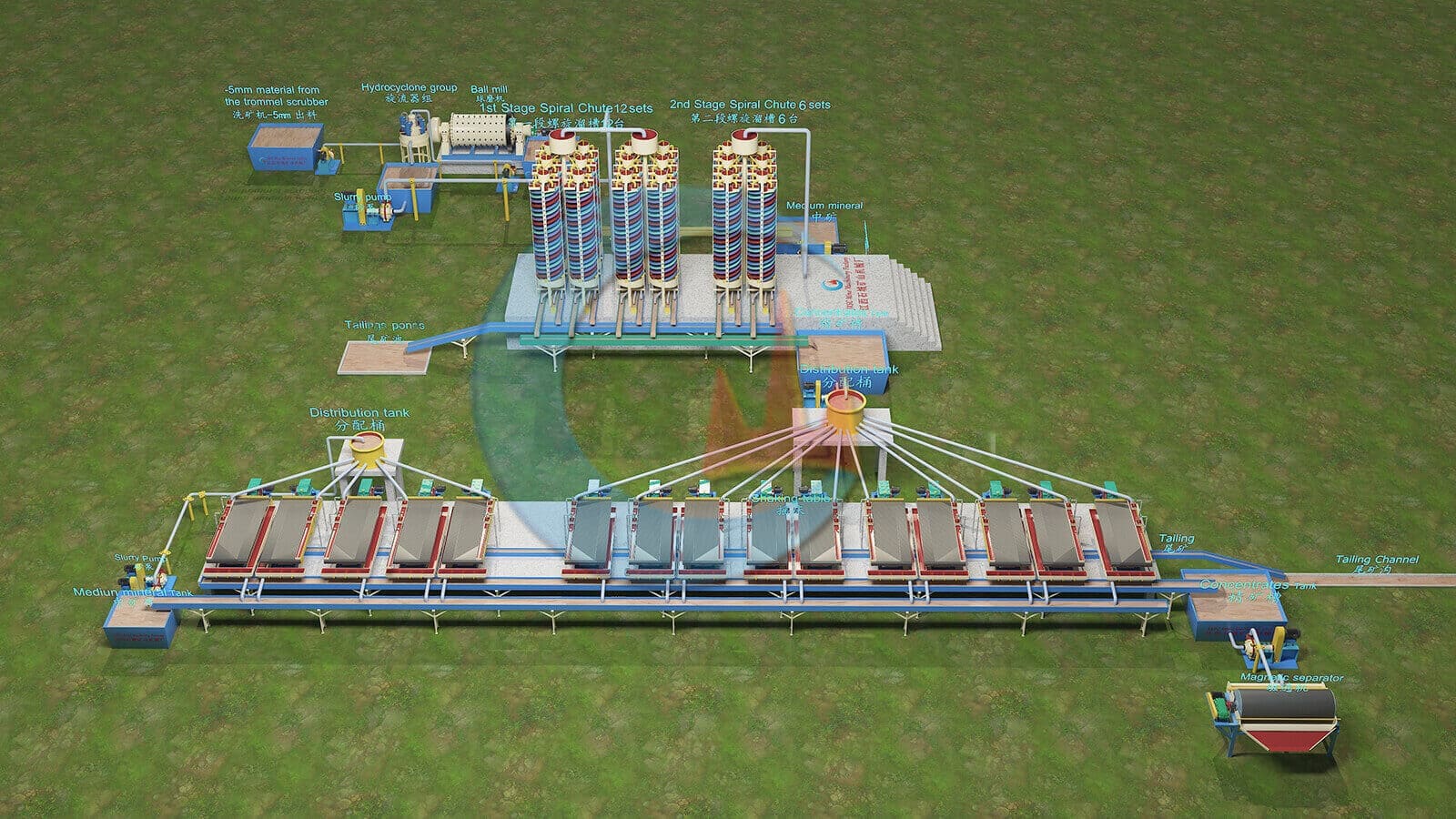

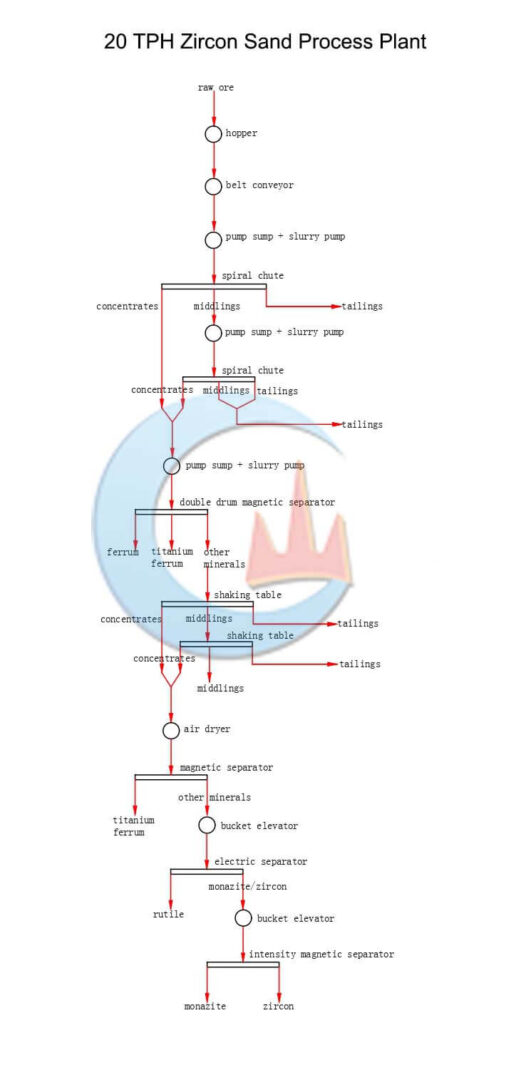

The process is as follows:

- The raw ore is fed into the raw ore bucket above the vibrating feeder by excavators, loaders, etc. The vibrating feeder is equipped with a grid with a 70mm gap; ore smaller than 70mm can be evenly fed into the trommel scrubber.

- The ore smaller than 70mm enters the trommel scrubber for washing (the trommel washer is equipped with two layers of screens with apertures of 7mm and 25mm, respectively). After washing, three types of ores can be obtained: 0-7mm, 7-25mm, and +25mm.

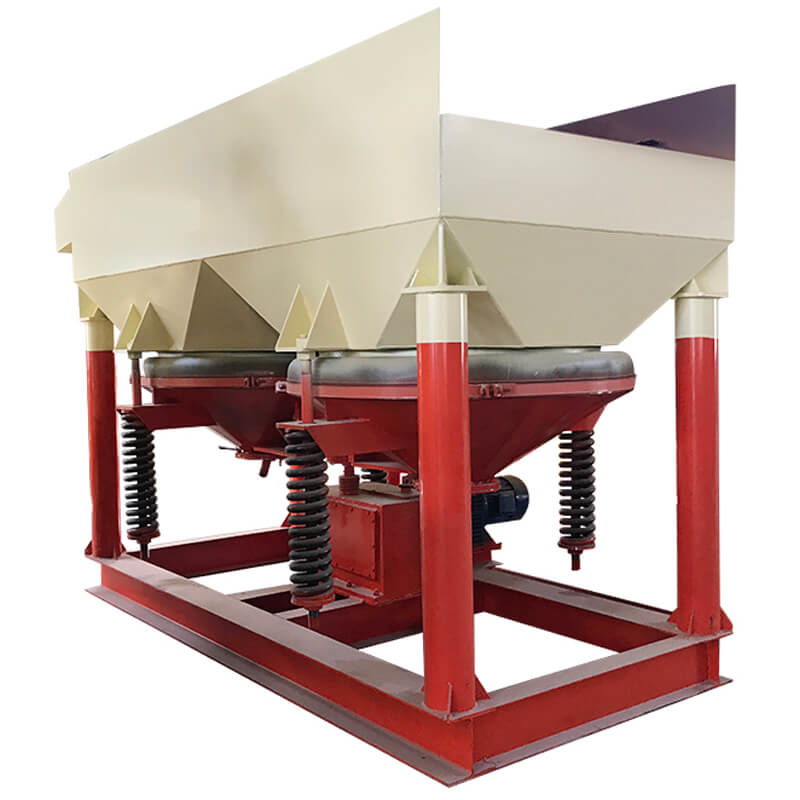

- After washing in the trommel scrubber, the ore larger than 25mm is sent to the ore pile by a belt conveyor. The 7-25mm ore enters a group of roughing jig separators for roughing; the concentrate enters a group of fine jigs for further separating. 0-7mm enters another roughing jig concentrator for enrichment. Then, the concentrate will also enter a cleaner jig concentrator for further separation. The tailings of the roughing jig concentrator will enter a scavenging jig for further concentration. These circled loop jig separators here can improve the recovery rate.

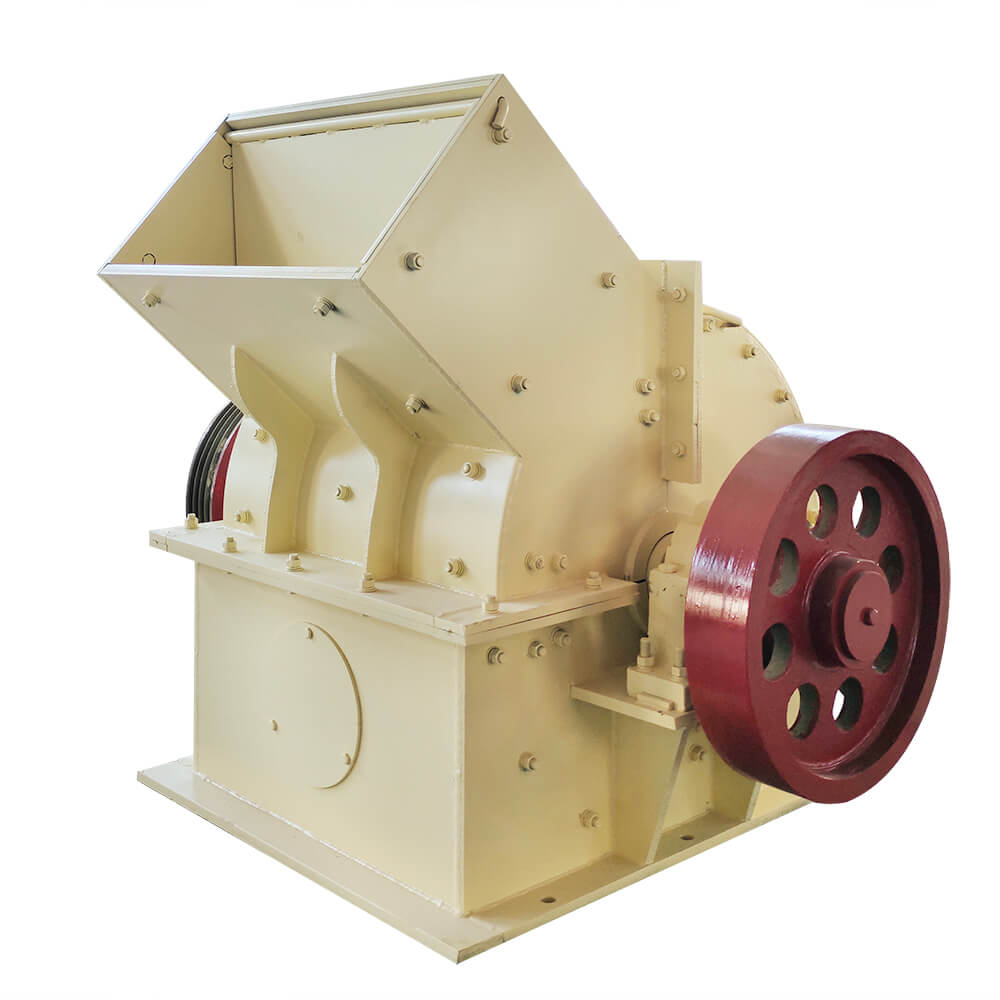

- Since there is a lot of water flowing out with the concentrate, all the concentrate from the jig separators will first enter the dewatering screen for dewatering. After dewatering, the particles on the screen will enter the hammer crusher through a belt conveyor. The undersize will be pumped to the mixing tank by a mud pump. The output of the hammer crusher will flow into the same mixing tank by gravity flow.

- The shaking table further separates to obtain a purer tin concentrate. The output concentrate needs to be directly dried, and then the dry concentrate can be put into 3 disc dry magnetic separators for refining to obtain high-purity tin concentrate.

- The tailings from these jig separators and the tailings from the shaking table will first enter the spiral dewatering machine for dewatering, and then enter the high-frequency vibrating screen for screening. Finally, two products of coarse sand and fine sand are obtained.

FAQ during communication:

Question: Can JXSC provide an agitated feed tank for the shaker table?

Answer: Yes, we can provide the agitated feed tank before the shaker table.

Question: Control panel layout Diagram

Answer: We can provide the electric control panel, just additional cost will be needed. The electric wire & cable layout will be provided after the order is placed.

Question: Installation/construction Schedule

Answer: Installation time around 1.5 months, based on all things being ready at your side and your workers being cooperative, etc.The time for reference

Question: Provide a basic labour schedule for the operation of the plant

Answer: Total at least 5 persons are needed to run the plant.

1 manager

1 for feeding+trommel

1 for jigs

1 for shaking table+crusher

1 for spiral washing +vibration screen

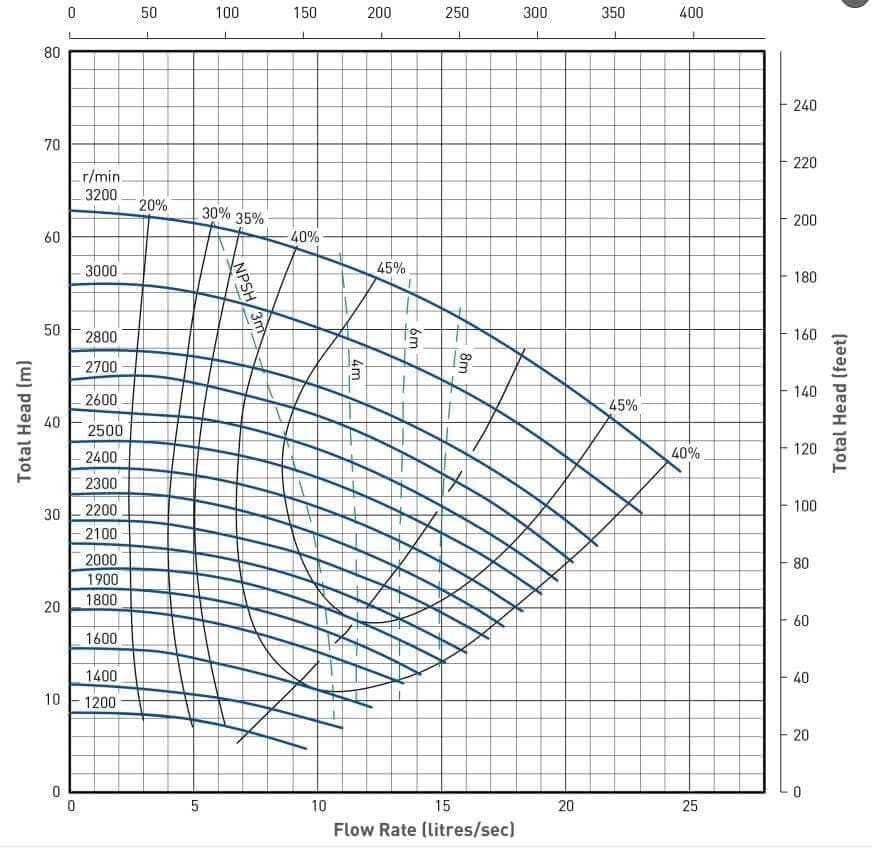

Questions: Sand Pump Curves

Answer: See the individual attachment for your reference.

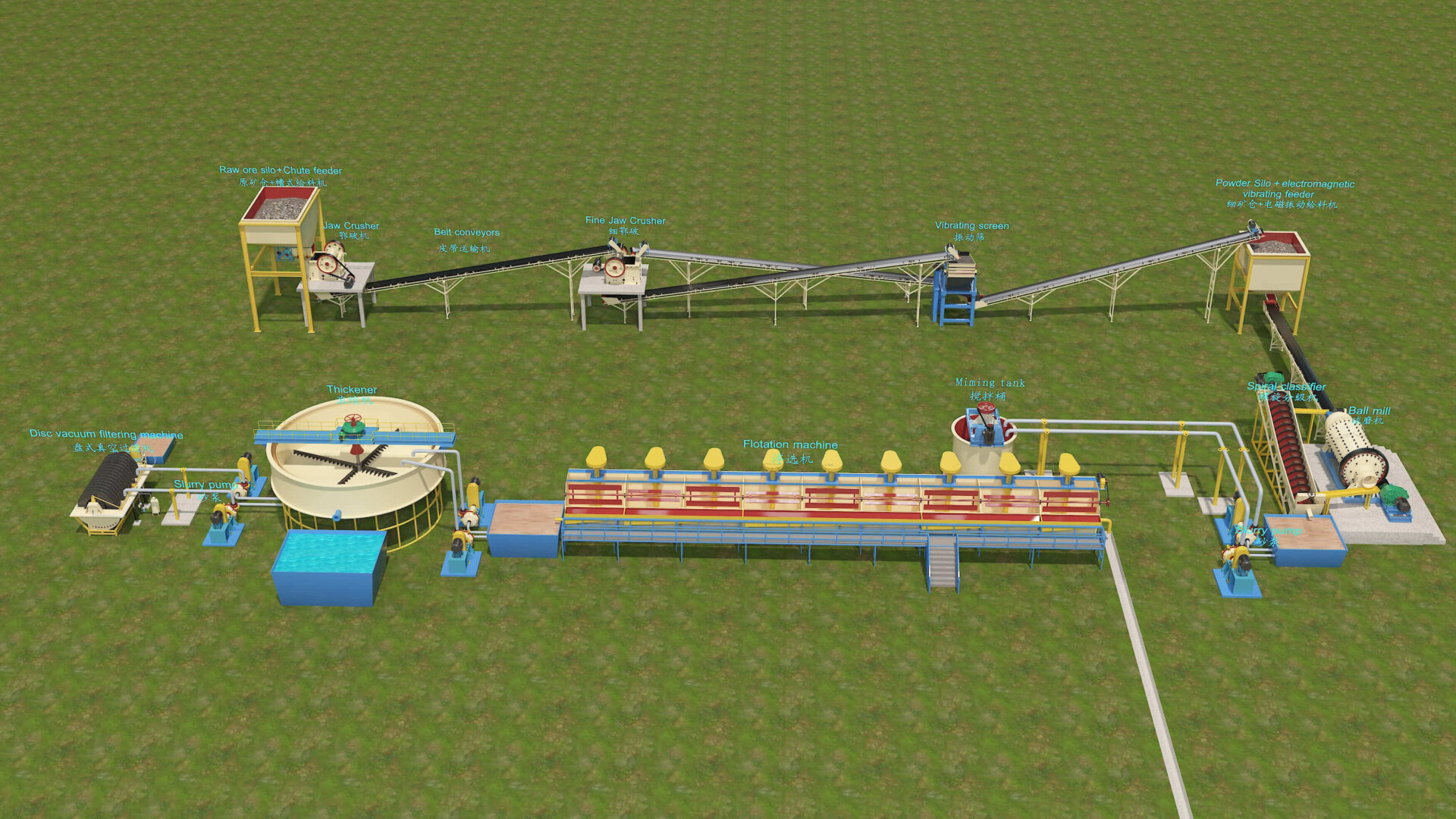

Equipment In This Project

Related Cases

We are a leading provider of innovative and efficient mining equipment and solutions. With years of experience in the industry, we specialize in designing and manufacturing high-quality machines tailored for various mineral processing needs, including gold, diamond, copper, tin, manganese, chrome, titanium, and other ore separations. Our commitment to technology and customer satisfaction drives us to deliver customized solutions that enhance productivity and ensure environmentally sustainable practices. Explore our extensive portfolio of successful case studies and discover how JXSC can transform your mining operations, helping you maximize your profitability while minimizing your ecological footprint. Choose Us—where technology meets efficiency in the world of mining!