Home » Equipment » Auxiliary Equipment » Double Spiral Feeding Machine

Double Spiral Feeding Machine

The double screw feeder is a precision feeding device that uses two parallel screw shafts to rotate synchronously or counter-rotating. It is designed to solve the problems of large flow, mixing uniformity, or high-viscosity material transportation.

Feeding Capacity: 10-160 t/h

Power: 2.2-30 kW

Application: Widely used in various industrial sectors, such as building materials, electric power, chemical industry, metallurgy, coal, aluminum and magnesium, machinery, light industry, grain, and food industries.

Double Spiral Feeding Machine Overview

The spiral feeder is also called a screw feeder and screw conveyor. It is the same type of conveying equipment as a scraper conveyor and a bucket conveyor. But one different thing is that the screw feeder is to achieve the effect of uniform feeding, and the focus is on the accuracy of the conveyed weight or volume.

The double spiral feeding machine is mainly used in industries that transport powdery and small-diameter particles. It usually works in the horizontal direction and is suitable for feeding under silos in metallurgical building materials, the chemical industry, food machinery, and other industries. It is widely used in the processing industry.

Compared with other conveying equipment, the double spiral feeder has high conveying efficiency, stable operation, safe and reliable operation, simple structure, can be loaded and unloaded at multiple points in the middle, complete functions, good sealing, low noise, beautiful appearance, easy operation & safety, simple maintenance, and other advantages.

Features

1. The screw feeder has a simple structure, a small cross-sectional size, and good sealing performance.

2. Conveying materials uniformly and stably, with high conveying volume accuracy.

3. The conveying volume can be controlled by adding frequency converter adjustment.

4. It has the functions of stirring and loosening materials at the same time during the conveying process.

5. Easy to operate, safe and convenient, and low manufacturing cost.

Details

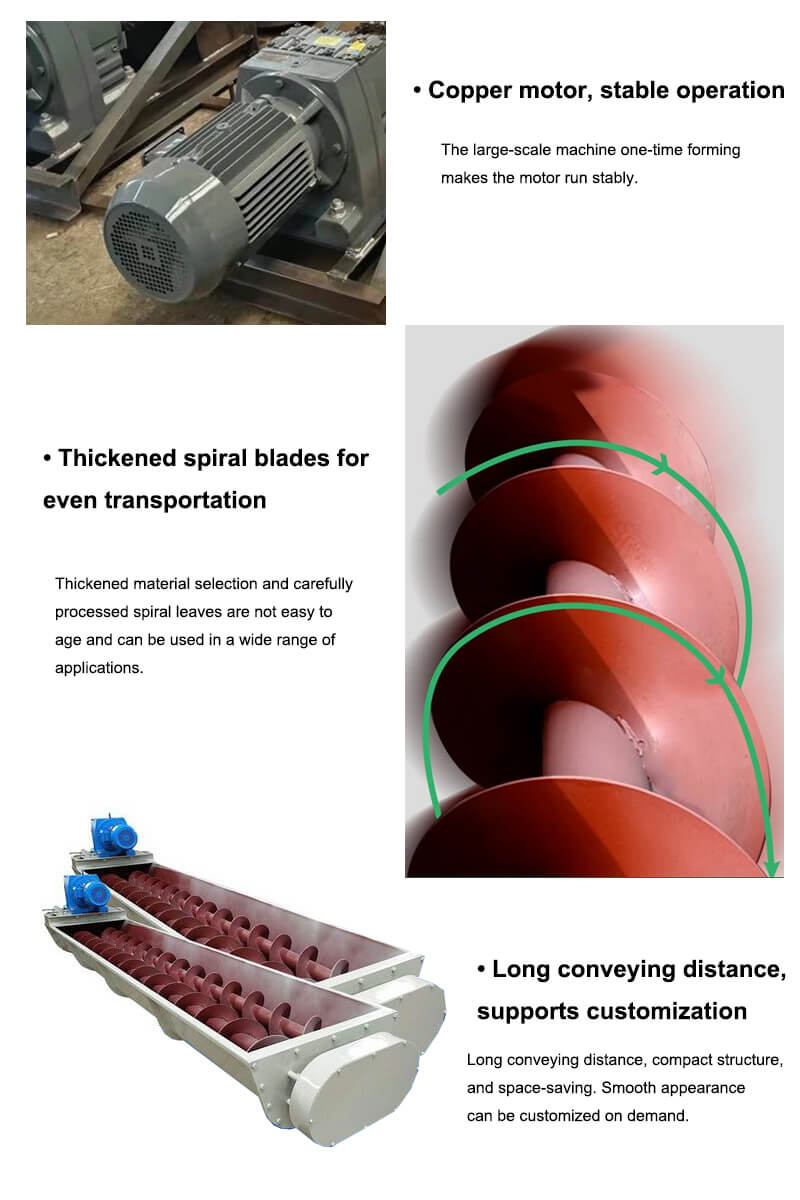

- Copper motor, stable operation

The large-scale machine one-time forming makes the motor run stably.

- Thickened spiral blades for even transportation

Thickened material selection and carefully processed spiral leaves are not easy to age and can be used in a wide range of applications.

- Long conveying distance supports customization

Long conveying distance, compact structure, and space-saving. Smooth appearance can be customized on demand.

Advantages

Double Spiral Feeding Machine Advantages

1. Dual-axis design, large output

The two screws rotate through a pair of gears at the extended position of the shaft. The double-shaft blades have a larger conveying flow rate per unit time than the single-shaft blades. According to test data, the double-screw feeder’s conveying capacity is 1.5-1.5 times that of the single-screw feeder. 2 times.

2. Not easy to accumulate and block

The two seamless steel pipes are equipped with solid screws respectively, and the screw shafts on both sides turn in different directions to avoid material blocking caused by material accumulation.

3. Low cost

The twin-screw feeder increases the mixing speed when working, which is equivalent to the mixer mixing materials at the same time, but the price is lower than the mixer, saving costs.

4. Long service life

The adoption of a variable diameter structure increases the volume of the suspension bearing and prevents friction between the suspension bearing and the material. The service life can reach more than two years.

5. Good sealing

All bearings use multi-layer sealing boxes as material seals, so materials will not spill out or be contaminated by other dust.

Structures & Working Principle

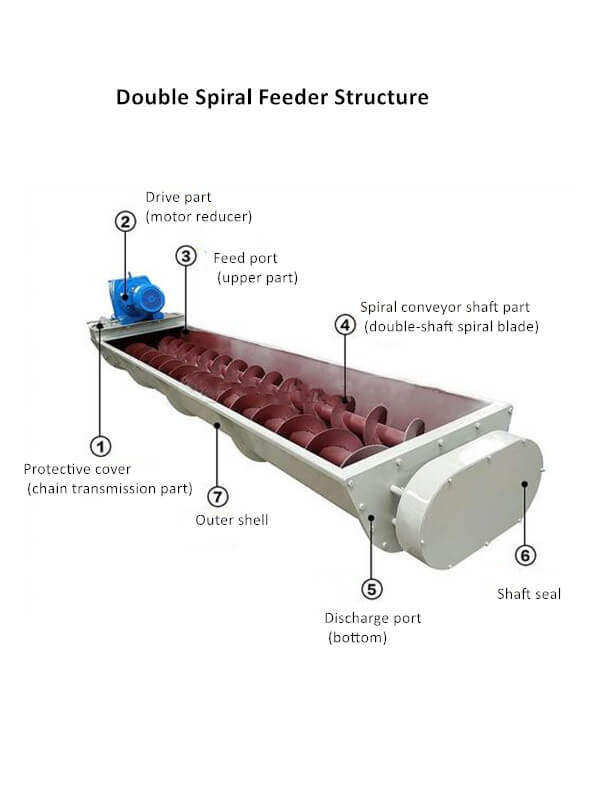

Double Spiral Feeder Structure

The basic components of a double spiral feeder are the driving device (motor, reducer, coupling), conveying device (double spiral tube), inlet, and outlet bins.

Double Spiral Feeder Working Principle

The working principle of the double screw feeder mainly relies on the design of two solid spirals. These two spirals are installed in two seamless steel pipes, one is left-handed and the other is right-handed. When working, the two spirals mesh and rotate through a pair of gears at the shaft extension position, causing the spiral body to rotate, the material moves axially along the spiral direction to achieve the purpose of conveying the material.

In addition, the distance between the two screw shafts of the double screw conveyor can be adjusted to accommodate materials of different sizes and shapes. The shape and length of the screw shaft can also be customized according to different material conveying usage scenarios. During the material transportation process, if there is any undesirable situation such as blockage, the double-tube screw feeder can also realize reverse discharge to ensure the normal operation of the equipment.

Technical Parameters

| Model | Spiral Diameter (mm) | Feeding Capacity (t/h) | Motor Power (kW) | Length |

| XL315 | 315 | 10-20 | 2.2 | Customized |

| 2XL315 | 315 | 20-35 | 2.2×2 | |

| XL500 | 500 | 35-50 | 5.5 | |

| 2XL500 | 500 | 40-60 | 5.5×2 | |

| XL750 | 750 | 50-70 | 11 | |

| 2XL750 | 750 | 80-120 | 11×2 | |

| XL1000 | 1000 | 60-80 | 15 | |

| 2XL1000 | 1000 | 120-160 | 15×2 |